Cable connector plug

A cable connection and plug technology, which is applied in the direction of conductive connection, connection, clamping/spring connection, etc., can solve the problem of cable shortening, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

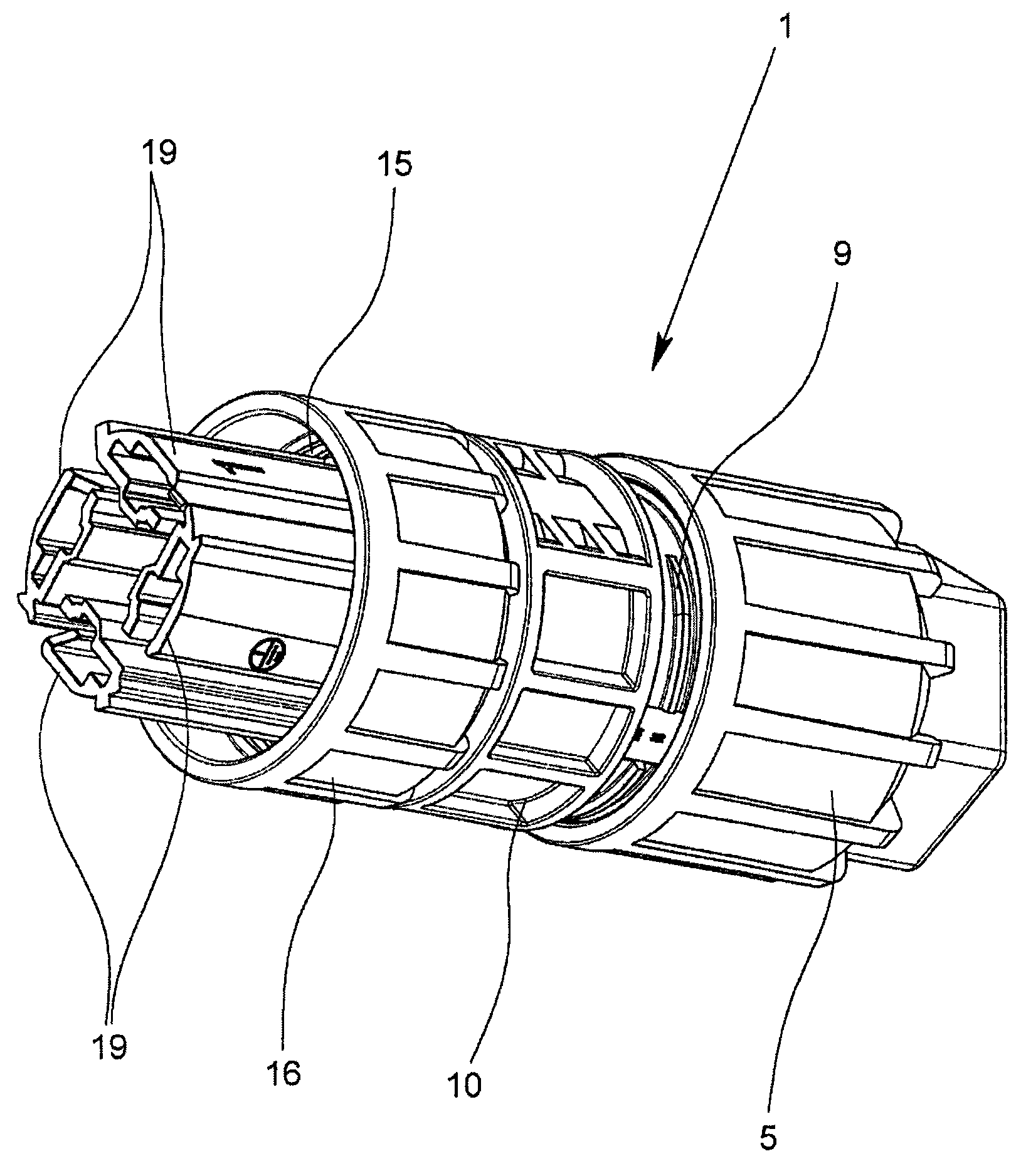

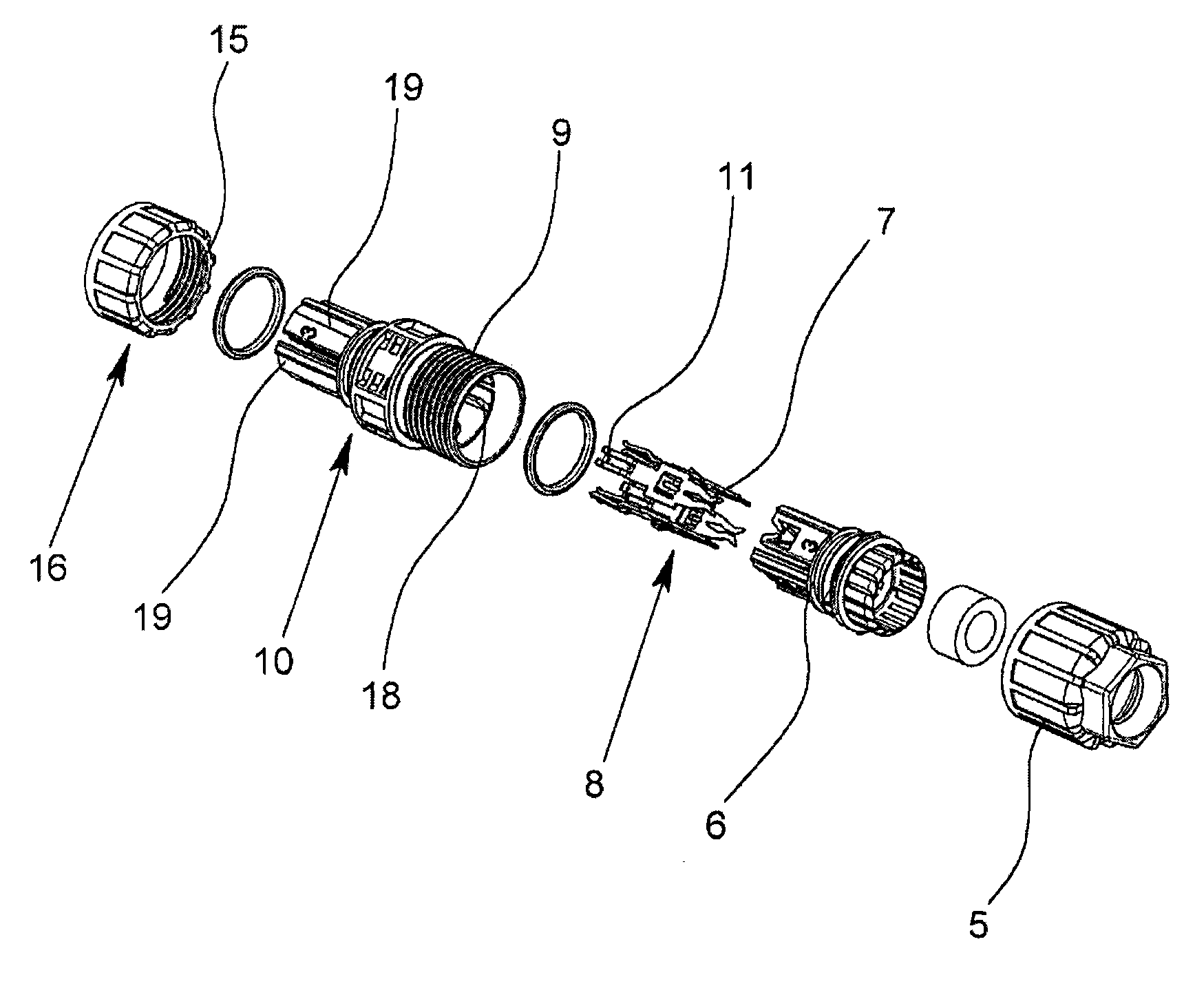

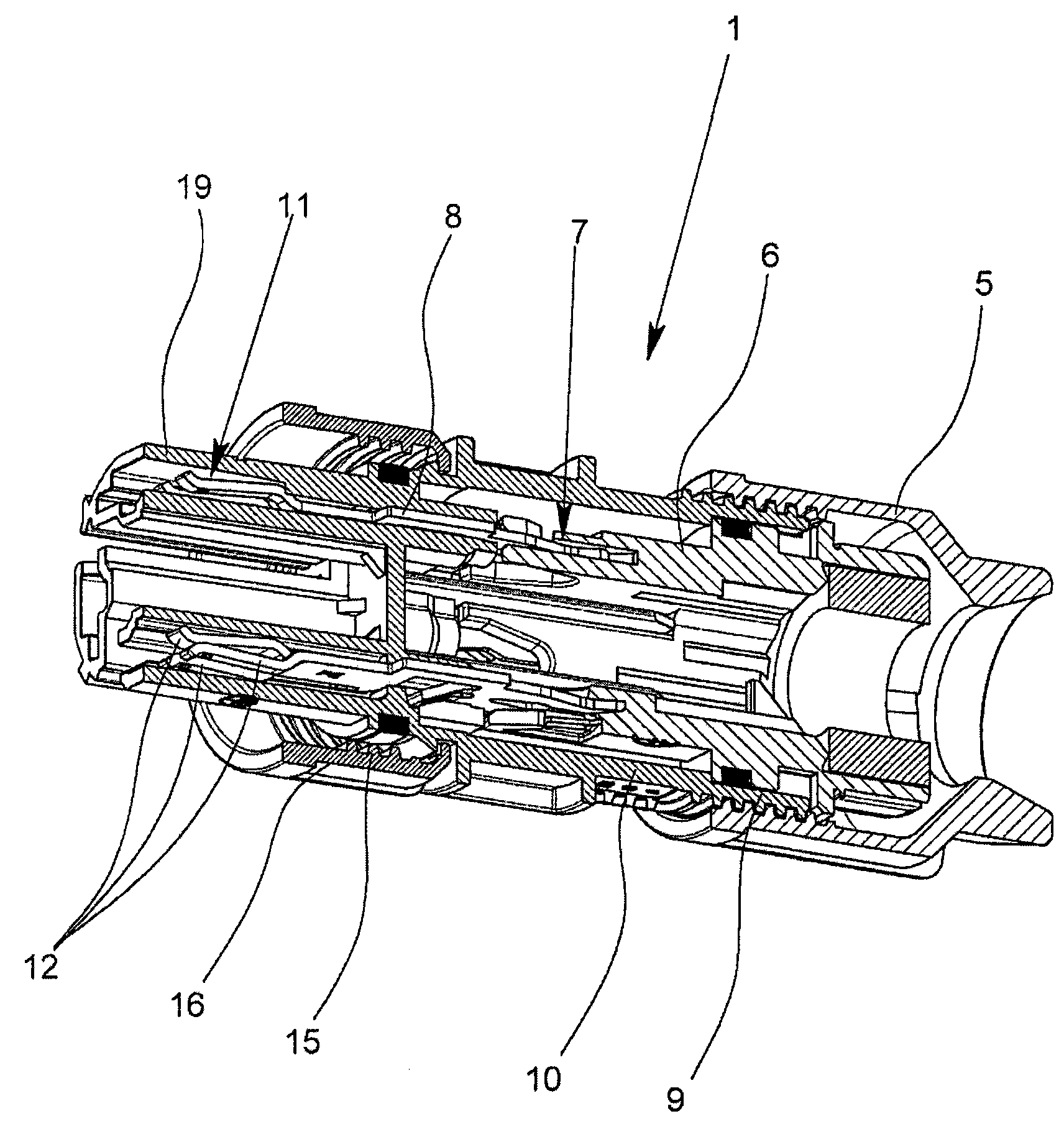

[0032] Figures 1 to 3 shows a socket for connecting a quad cable not shown here to the Figure 4 Cable connection plug 1 on connection device 3 with cut terminal 2 of electrical distributor 4 shown in .

[0033] The cable connection plug 1 comprises in particular a union nut 5, a conductor receiving and guiding element 6, four contact elements 8 each having a cut-off terminal 7 on their side facing the cable to be connected, and one having and The internal thread of the locking nut corresponds to the connecting body 10 of the external thread 9 . To connect a cable to the cable connection plug 1 , the union nut 5 is first pushed onto the end of the cable from which the cable insulation has been removed. The individual cores are then inserted into the core guides of the core receiving and guiding element 6 in order to press the cores into the cut terminal when screwing the union nut onto the connecting body 10 7, whereby the cutting terminal 7 cuts the insulating layer of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com