Single-phase reluctance generator

A reluctance generator, single-phase technology, applied to synchronous motors with static armatures and rotating magnets, synchronous machine parts, magnetic circuit rotating parts, etc., can solve the problem that permanent magnet rotors cannot use claw-pole rotors, Increase the manufacturing cost, operating cost, one-way current in the power generation state, etc., to achieve the effect of improving efficiency, reducing equipment cost, and increasing power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

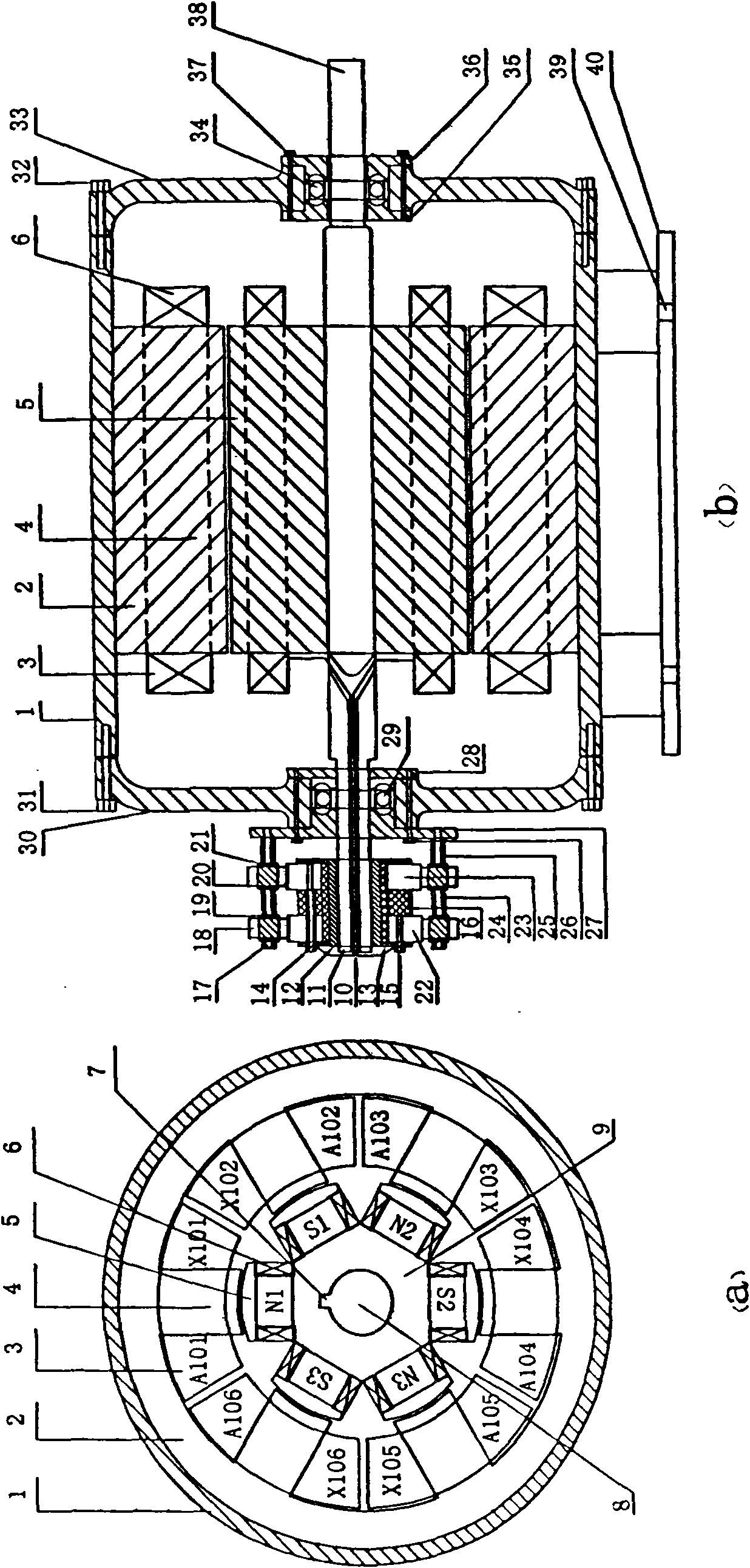

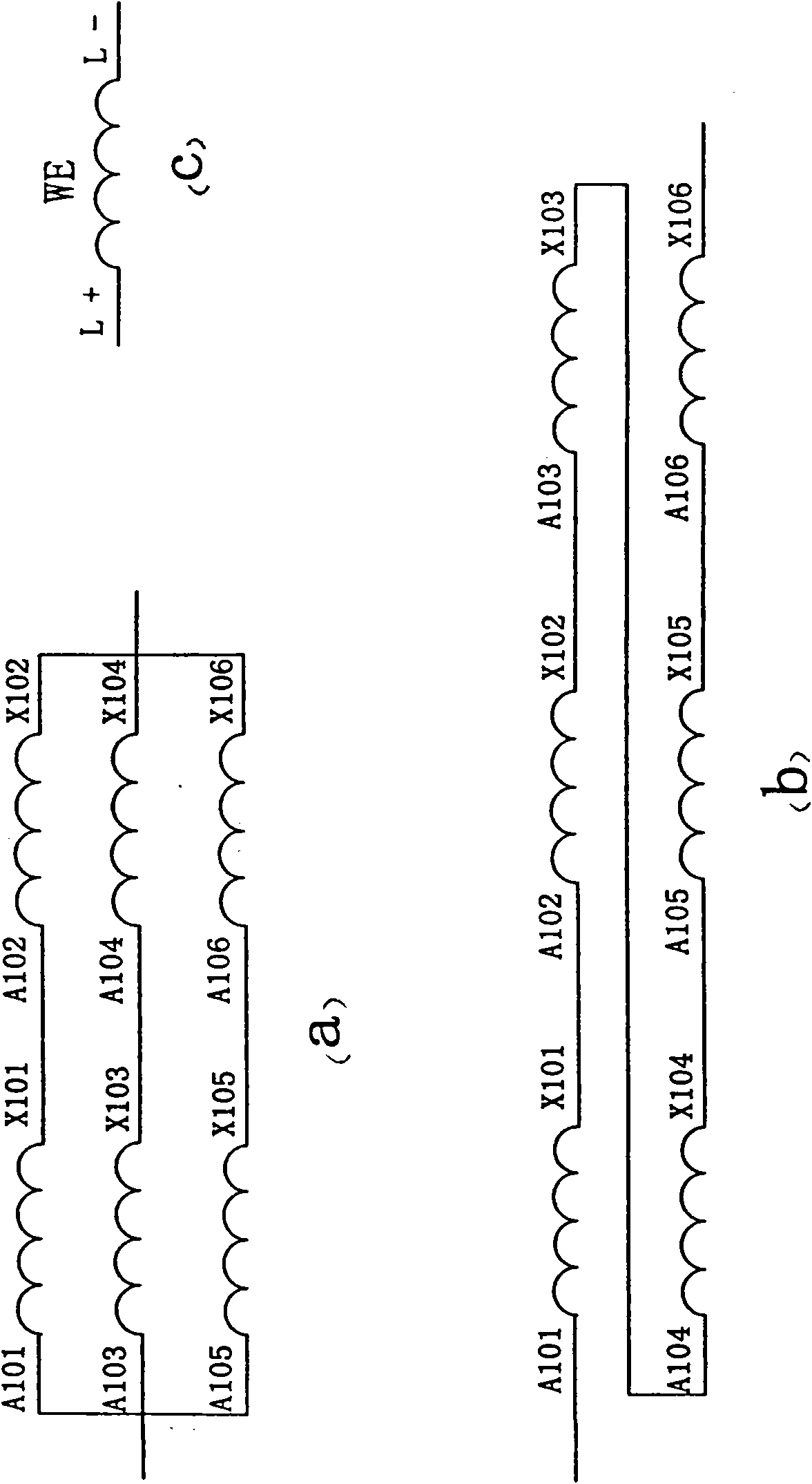

[0039] Such as figure 1 a, b and image 3 , Figure 5 As shown: the single-phase magnetic group generator consists of a stator and a rotor, both of which are laminated with silicon steel sheets to form a salient pole structure; the stator part includes the stator shell 1, the stator yoke 2, the stator armature winding 3, the stator pole 4 and the base 40, etc., the rotor part includes the rotor pole 5, the rotor field winding 6, the rotor yoke 9, the rotor shaft 11, and the front and rear bearings 29, 34, etc.; there are concentrated armature windings on the salient poles of the stator, and the windings are based on the N and S of the armature windings. The polarities are connected in series or in parallel to form a phase. Armature windings 3 are sheathed on the salient magnetic poles of the stator, and the armature windings on two adjacent salient poles of the winding 3 are connected in anti-phase series to form a set of windings, while the rotor windings are connected in a...

Embodiment 2

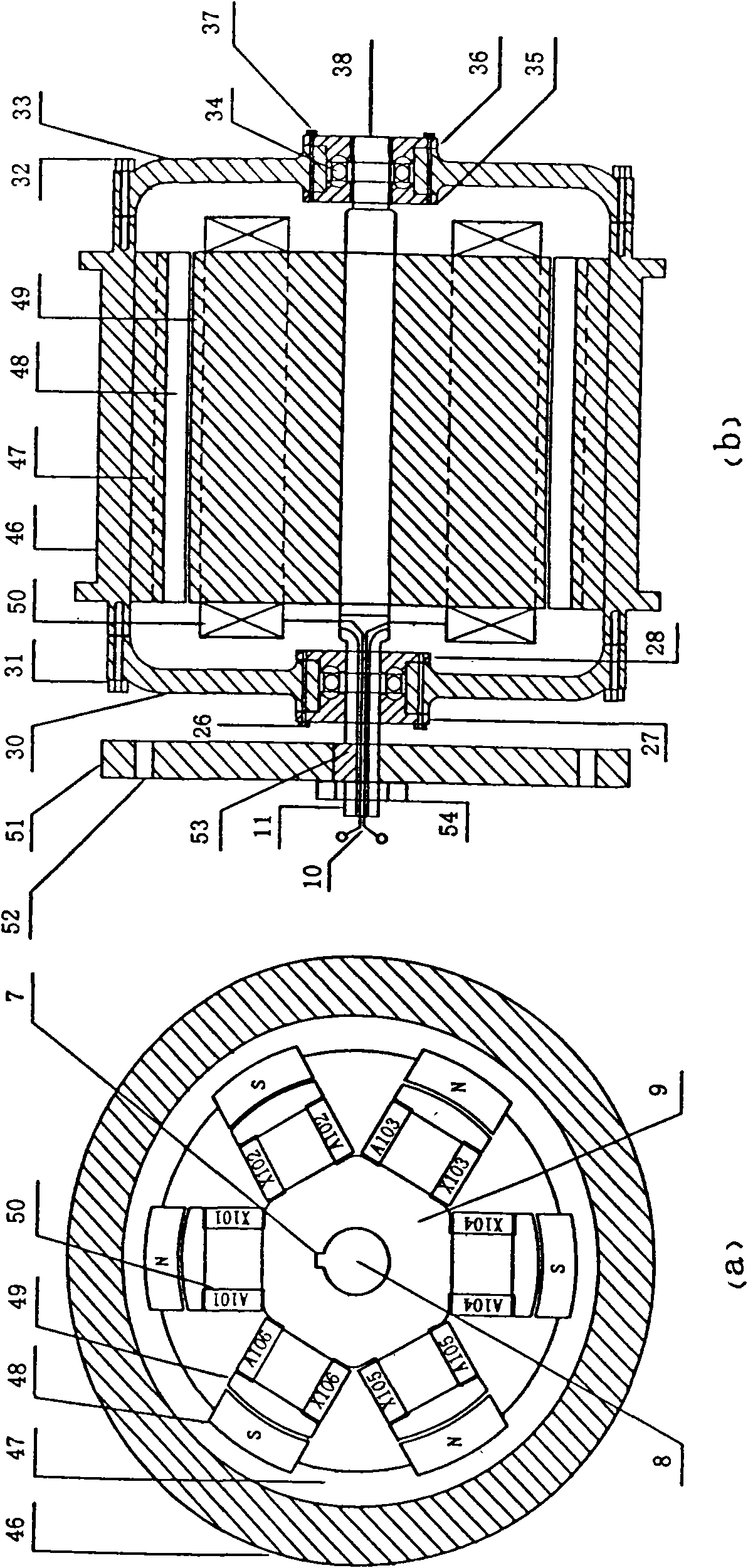

[0044] Such as figure 2 As shown in a and b: it is a single-phase 6 / 6 double-salient electric excitation type equal-pole outer rotor generator; the technology adopted is to change the rotor to a permanent magnet outer rotor, that is, neither the inner stator nor the outer rotor need to slide Ring (non-excitation), the shell 46 of the motor is a rotating shell or a rotating pulley; this technology only changes the electric excitation winding of the rotor into a permanent magnet outer rotor; its principle and application are the same as figure 1 The same; the stator armature series is the same image 3 b, parallel connection with image 3 a.

Embodiment 3

[0046] Such as Figure 4 As shown in a and b: it is a single-phase 8 / 8 double salient pole permanent magnet type equal pole inner rotor permanent magnet generator; the technology used is the outer stator inner rotor, which increases the number of poles (adding two more poles); the inner rotor magnet A permanent magnet pole 41 is fixed on the yoke 9, where the permanent magnet pole rotor does not need a slip ring. Its stator armature winding is 4-way or 2-way parallel connection can reduce the output voltage and increase the output current, 1-way series connection can increase the output voltage, and the output current is equal to the rated current of the winding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com