Crystal device for surface mounting

A surface mount, crystal technology, used in electric solid devices, semiconductor devices, electrical components, etc., can solve problems such as poor bonding, electrode roller speed changes, current fluctuations, etc., to improve productivity, increase allowable range, and increase welding efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

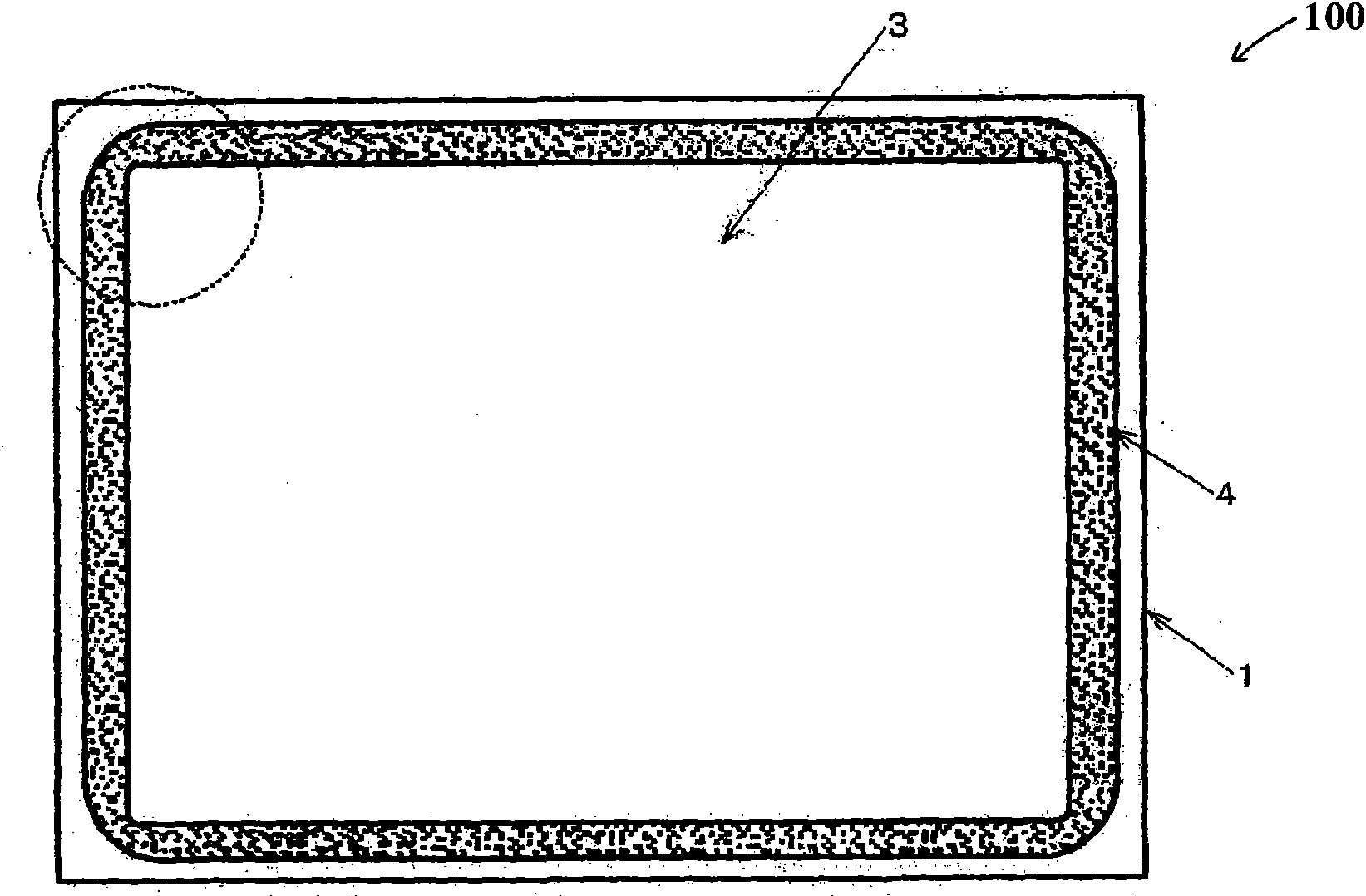

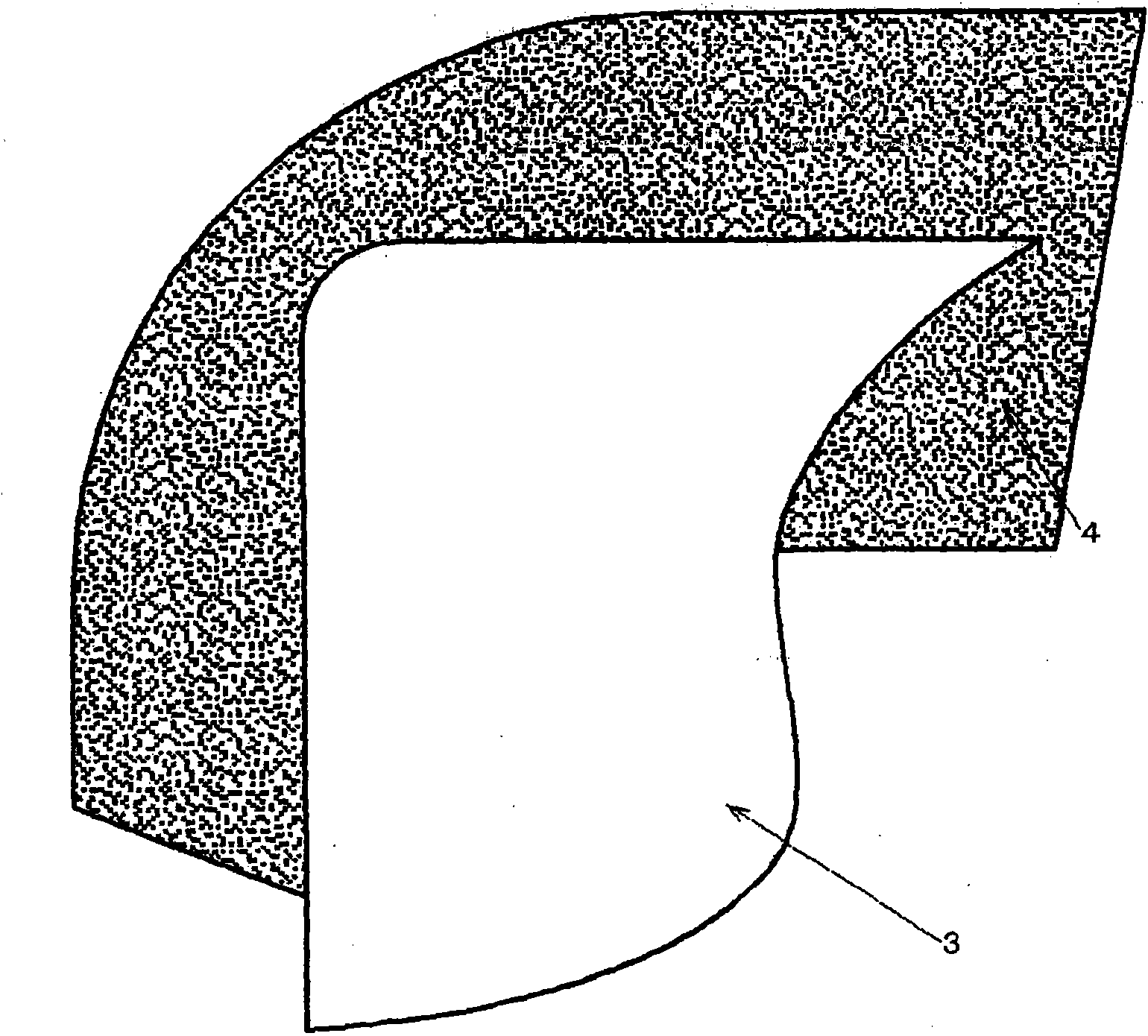

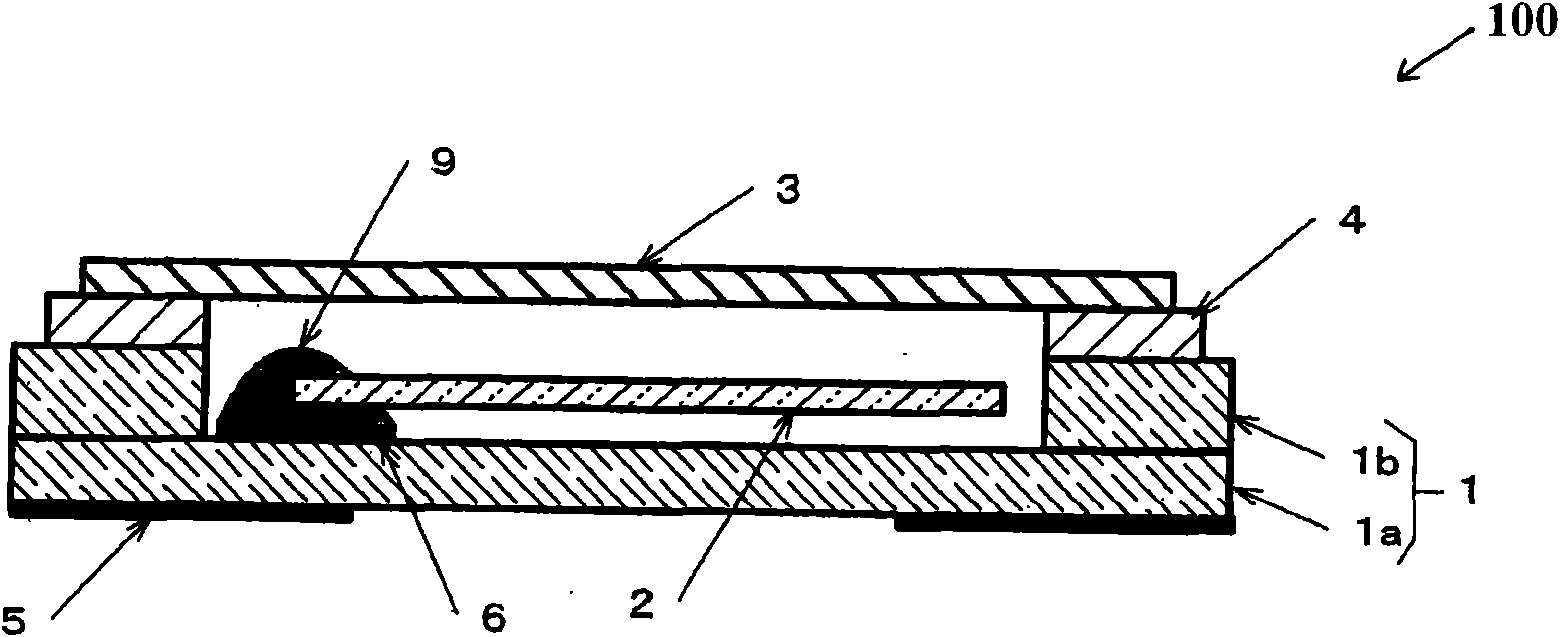

[0030] Figure 1A to Figure 2B is a schematic diagram of a surface mount unit used to illustrate an embodiment of the present invention, where Figure 1A is a plan view of the surface mount unit with the metal cover engaged, Figure 1B yes Figure 1A The magnified view of the part indicated by the O-shaped dashed line in , Figure 1C is a cross-sectional view of the surface mount unit, Figure 2A is the plan view of the ferrule of the surface mount unit, and Figure 2B It is a floor plan of the metal cap. Incidentally, the same parts as those in the related art are denoted by the same symbols, and their descriptions are simplified or omitted.

[0031] The surface mount unit 100 according to the present invention is constructed such that the crystal element 2 is housed in the ceramic case 1, and the metal cover 3 is bonded to the metal ring 4 which is provided on the end face of the opening by seam welding so as to be airtight Package the crystal element 2 . The ceramic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com