Method for grinding inner hole of front segment camshaft by external grinding machine

A cylindrical grinding machine, camshaft technology, applied in grinding machines, grinding/polishing equipment, machine tools designed for grinding the rotating surface of workpieces, etc. Large and other problems, to achieve the effect of convenient clamping, reduced labor intensity, and firm clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

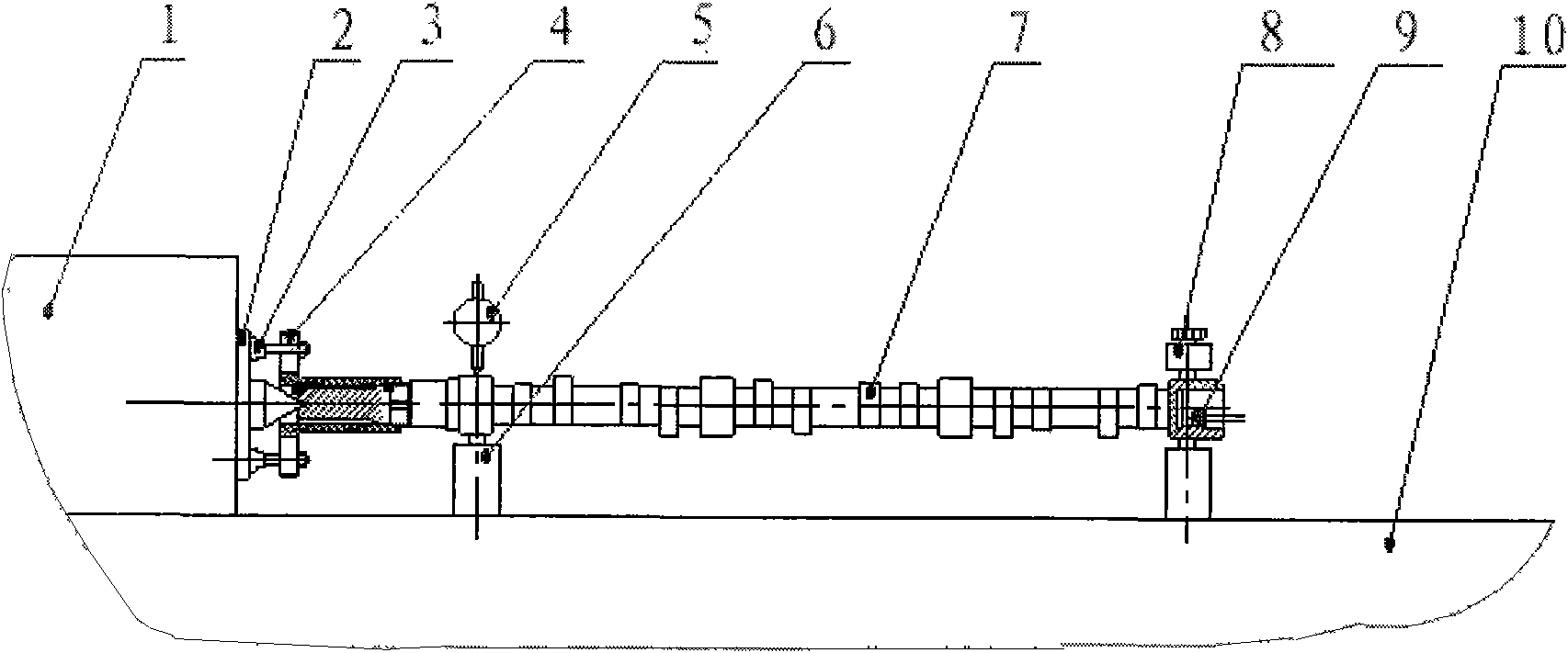

[0014] refer to Figure 1-Figure 3 , a method for cutting the inner hole of a front camshaft with an outer cylindrical grinder, comprising the use of an outer cylindrical grinder and an inner hole grinding tool. The headstock 1 of the grinding machine, the pulling disc 2 and the top of the headstock 1 of the grinding machine are in close contact with the center hole of the front section of the camshaft 7, so that the design datum, measurement datum and machining datum of the front section of the camshaft 7 coincide.

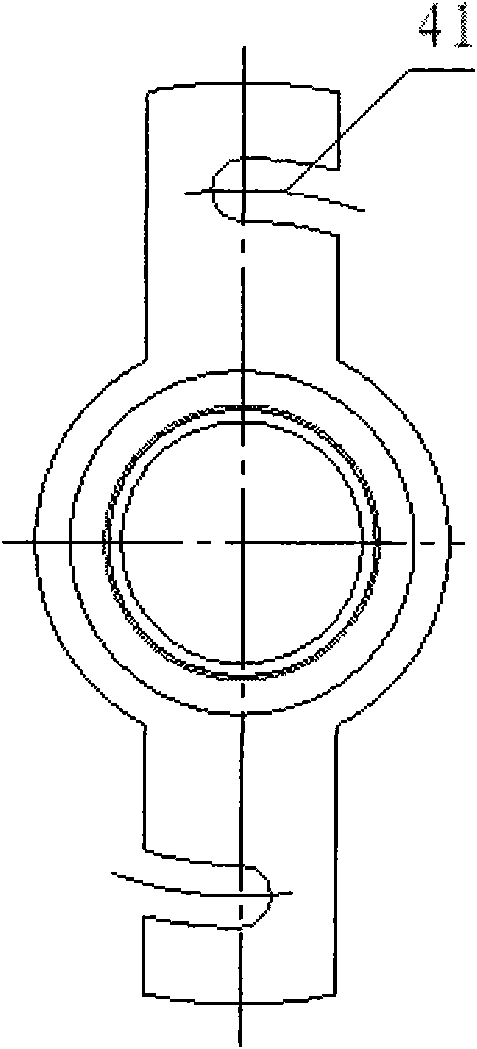

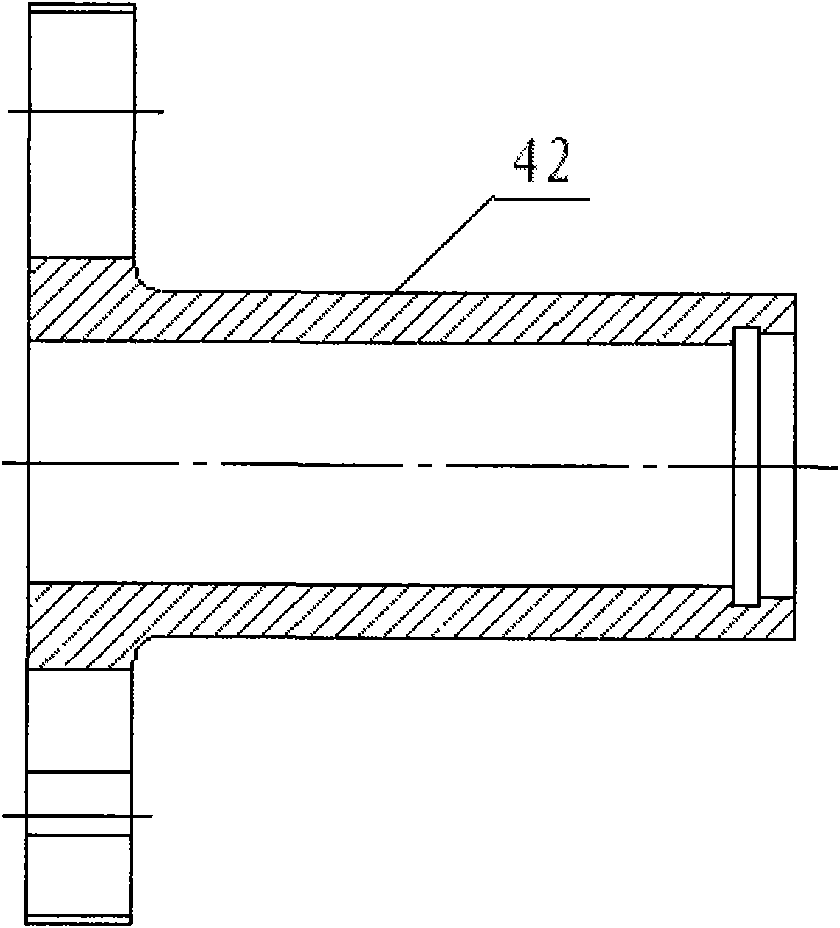

[0015] The camshaft 7 inner hole grinding tool 4 adopts the connection mode of the double U-shaped groove 41 and the grinding machine headstock 1. The camshaft 7 inner hole grinding tool 4 is connected with the front camshaft by M52×1.5 internal thread, and is axially tensioned with the camshaft 7 . The inner hole grinding tool 4 is a tubular structure with a connecting arm at one end, and the tubular body 42 is provided with an M52×1.5 internal screw. Both sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com