Method for laying geotextile underwater

A technology of geotextiles and gravel bags, which is applied in infrastructure engineering, coastline protection, construction, etc., can solve problems such as uneven weight of stones, stone crushing of 1 volume of drainage board, etc., to reduce maintenance frequency, ensure construction quality, The effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

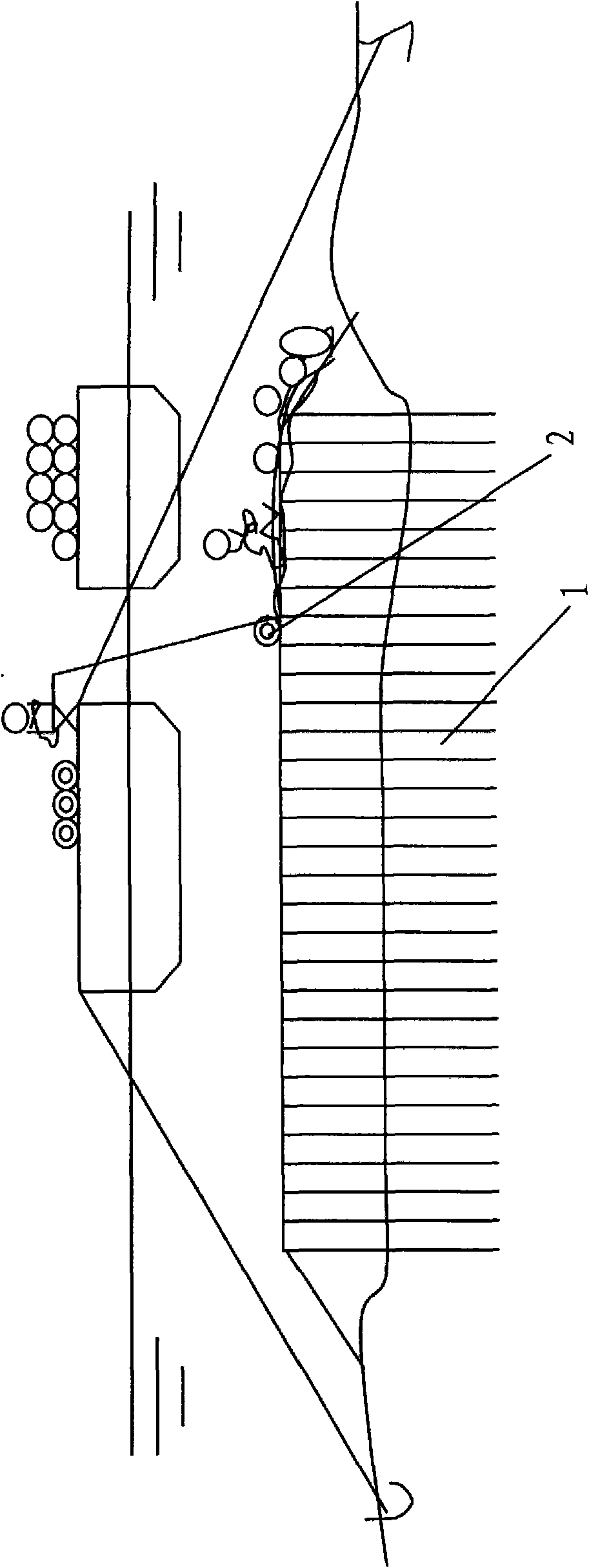

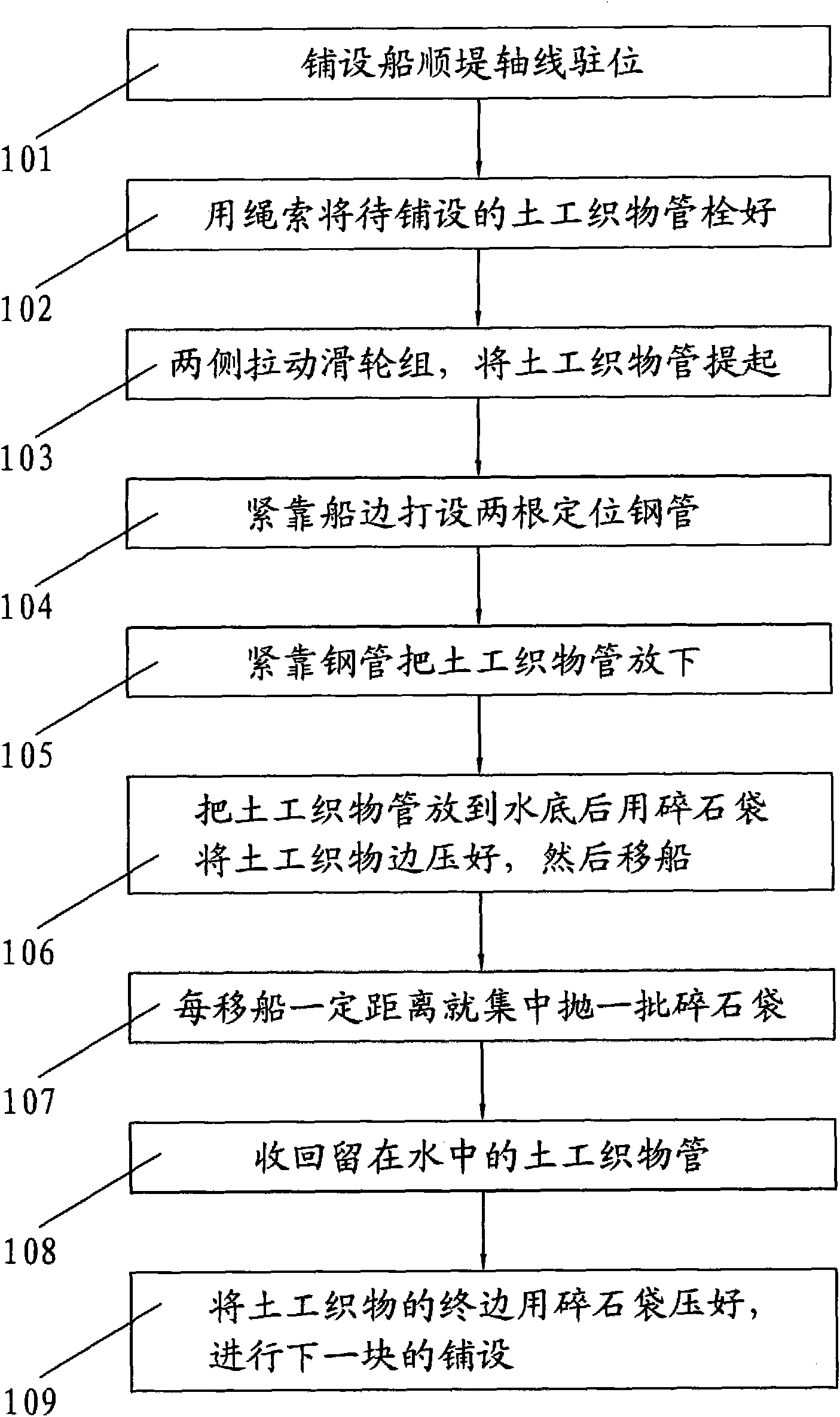

[0024] The method for underwater laying of geotextiles of the present invention preferably adopts the first self-propelled deck barge with a good mooring system as the laying ship. The laying ship has two mooring systems at the front and rear respectively, and two sets of pulley blocks are equipped on one side of the ship for lowering to be laid. geotextiles. In addition, a second self-propelled deck barge is required next to said laying vessel, which is used to carry bags of rubble and doubles as a diver's boat. The parking directions of the two self-propelled deck barges are along the dike axis, and the middle position of the two ships is the laying sideline. The distance between the two ships is about 0.4m-0.8m, which is just enough to lay down the geotextile. After the laying ship is in place, the divers go into the water, and the workers put down the geotextile that has been rolled up with steel pipes along the side of the ship. During the above-mentioned process of layi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com