High temperature air source heat pump hot-air fan used for drying

An air source heat pump, high temperature air technology, used in drying gas layout, dryer, drying and other directions, can solve the problems of low heating temperature, unable to meet the requirements of drying, overpressure protection shutdown, etc., to reduce the intake pressure , Simple and easy design, stable pressure reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

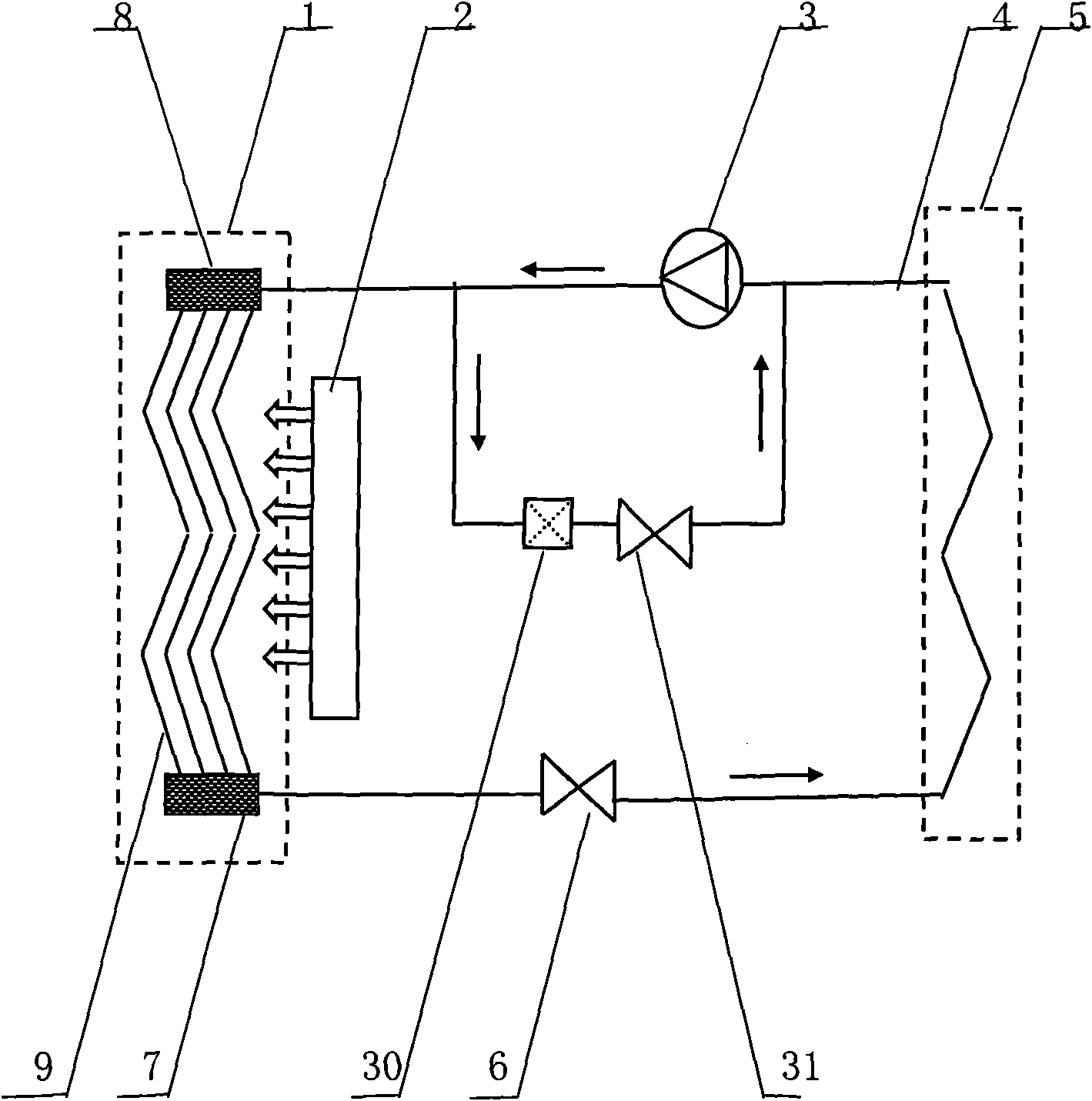

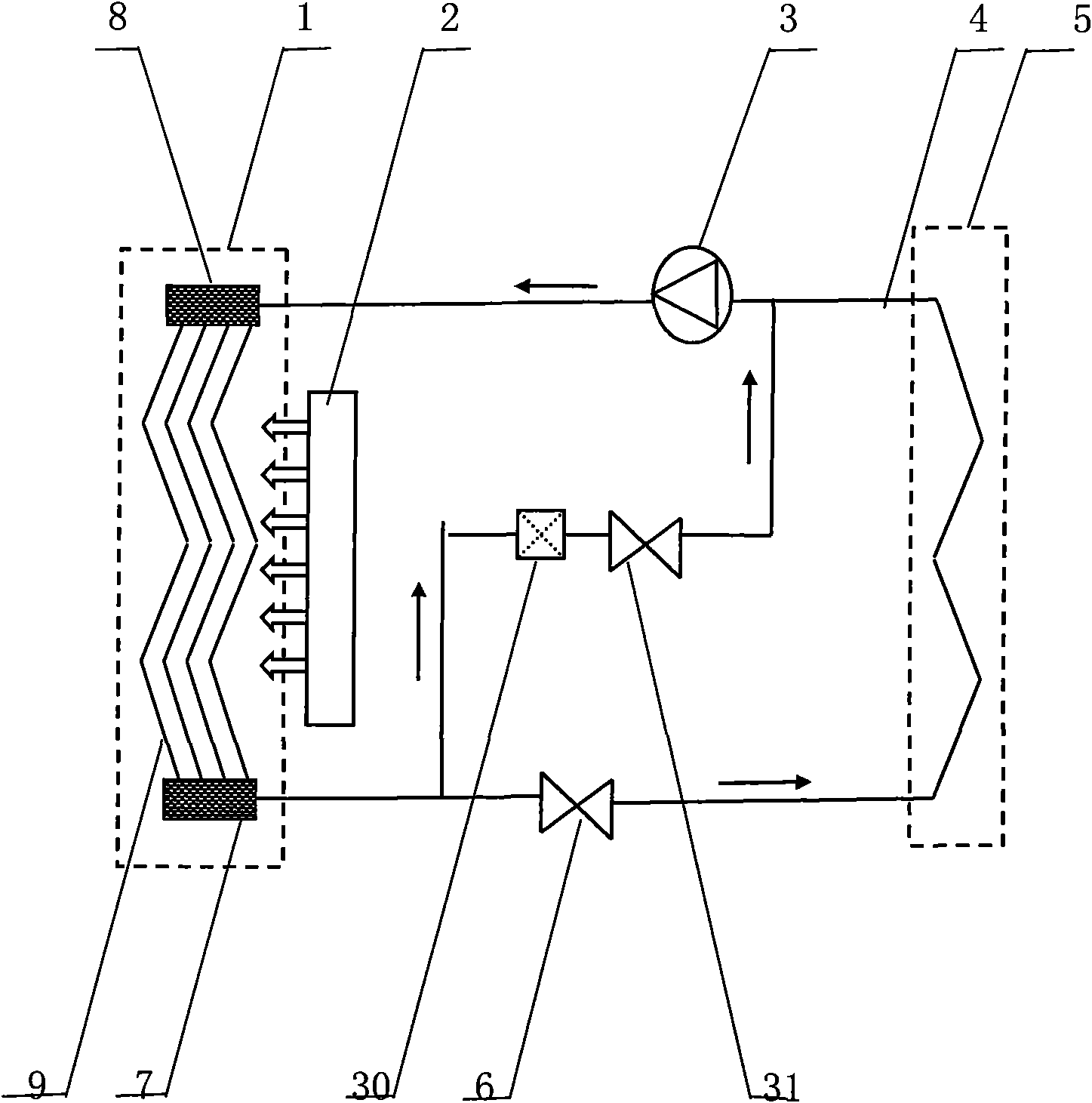

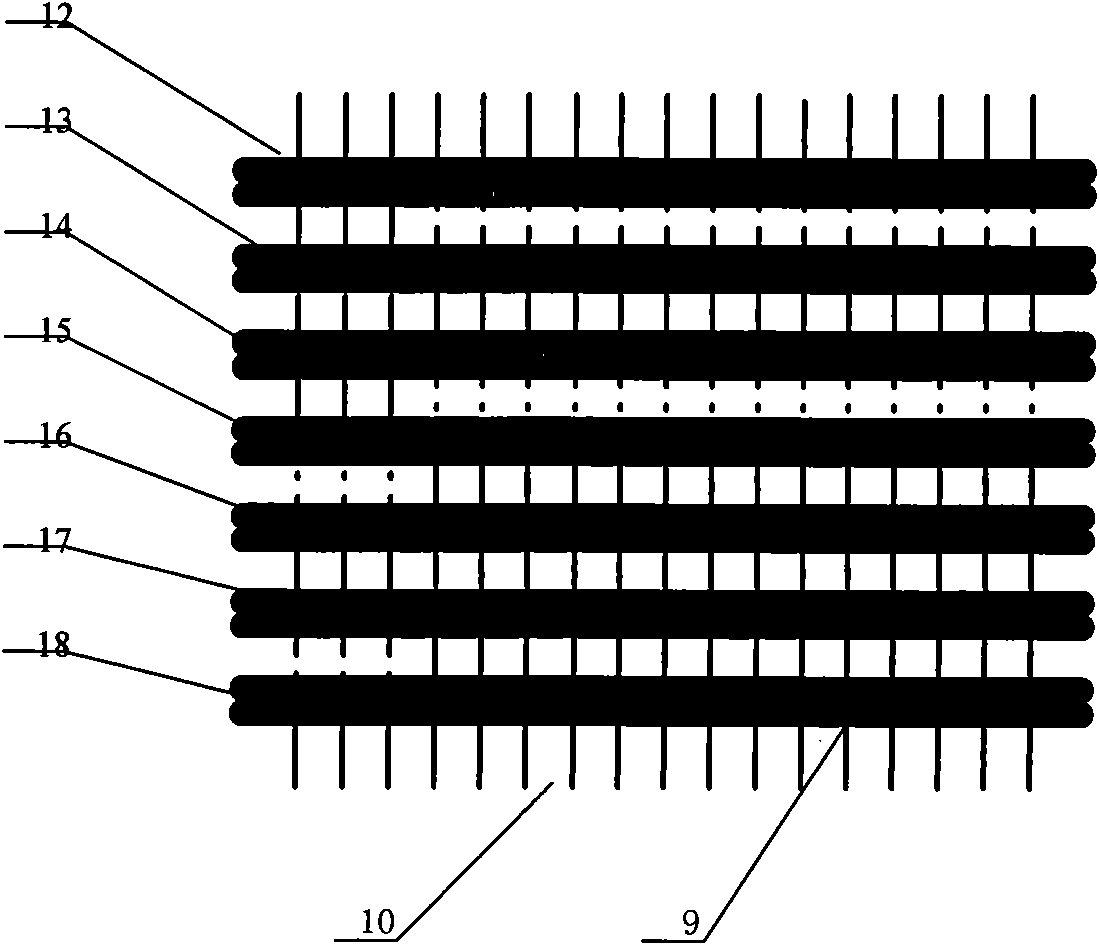

[0033] see figure 1 , reflecting a specific structure of the present invention, including an air source heat pump and a fan 2 mainly composed of an evaporator 5, a compressor 3, a condenser 1, and a main throttling device 6 connected with a working fluid circulation pipeline 4 in sequence. The hot air blower is also provided with a pressure relief diverter valve 30 and a secondary throttling device 31, the input end of the pressure relief diverter valve 30 is connected to the working fluid circulation pipeline 4 between the compressor 3 and the condenser 1, and the pressure relief diverter valve The output end of 30 is connected to the input end of the auxiliary throttling device 31 , and the output end of the auxiliary throttling device 31 is connected to the working medium circulation pipeline 4 between the evaporator 4 and the compressor 3 , and the connection point is close to the compressor 3 . Condenser 1 includes the air inlet and outlet on the shell and the shell and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com