Method for detection by ultrasonic guided wave signals

An ultrasonic guided wave and signal technology, which is applied to the analysis of solids using sonic/ultrasonic/infrasonic waves, can solve problems such as inapplicability to long-distance detection, and achieve the effect of accurate detection results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

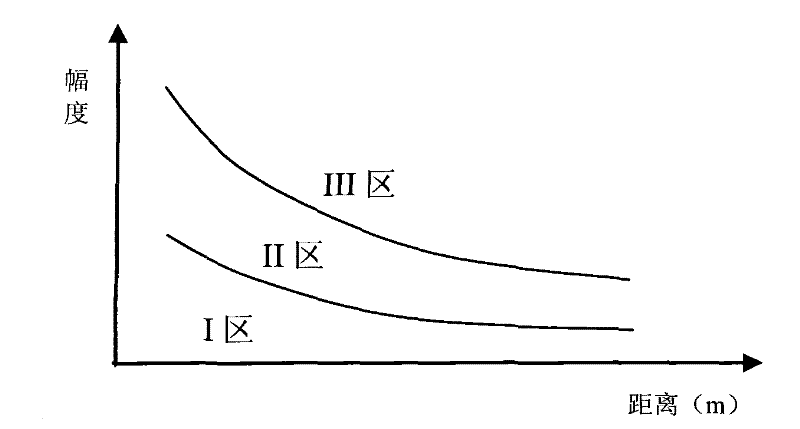

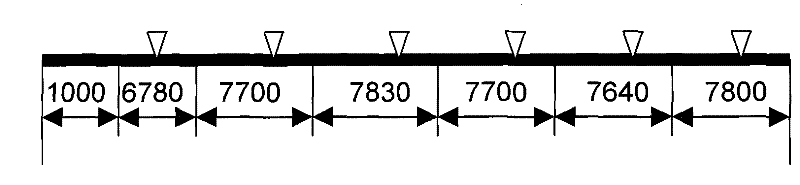

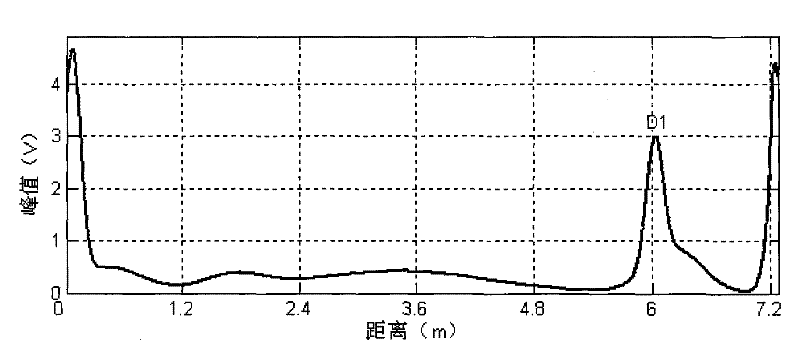

[0029] figure 1 A curve close to the coordinate system is the evaluation line, and a curve far away from the coordinate system is the waste judgment line. Make a standard sample pipe with an outer diameter of 57mm, a length of 46.45m, and a thickness of 3.5mm, and cut a groove with a sectional area loss of 12% at a distance of 1m from the left end. The sample pipe after cutting the groove is as follows: figure 2 as shown, figure 2 Among them, the first distance at the left end refers to the distance from the left end of the cut groove, the second distance refers to the distance from the first weld to the cut groove, and the distances after that refer to the distance be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com