Novel winding method for high-frequency transformer coils

A high-frequency transformer and coil technology, which is applied in the directions of transformer/inductor coil/winding/connection, inductance/transformer/magnet manufacturing, coil manufacturing, etc., can solve large energy loss, poor conversion energy efficiency, and high-frequency transformer loss and other issues to achieve the effects of improving conversion efficiency, saving production costs, and reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

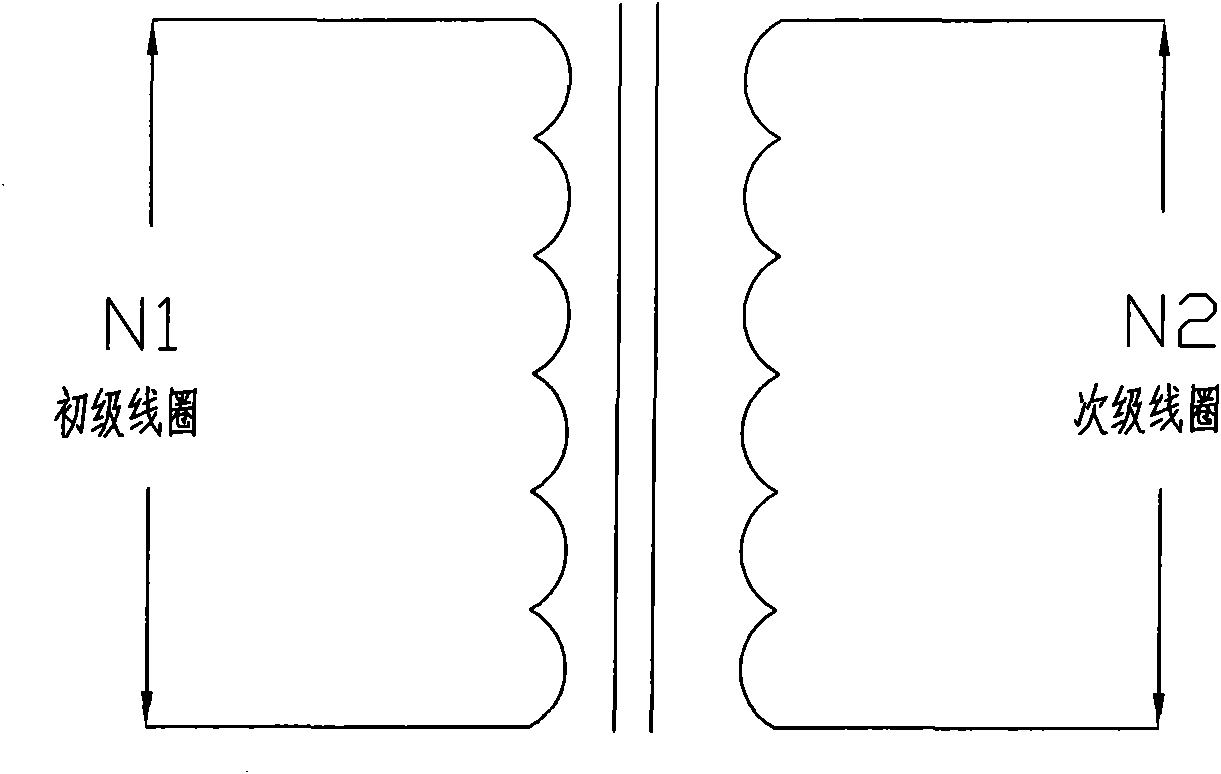

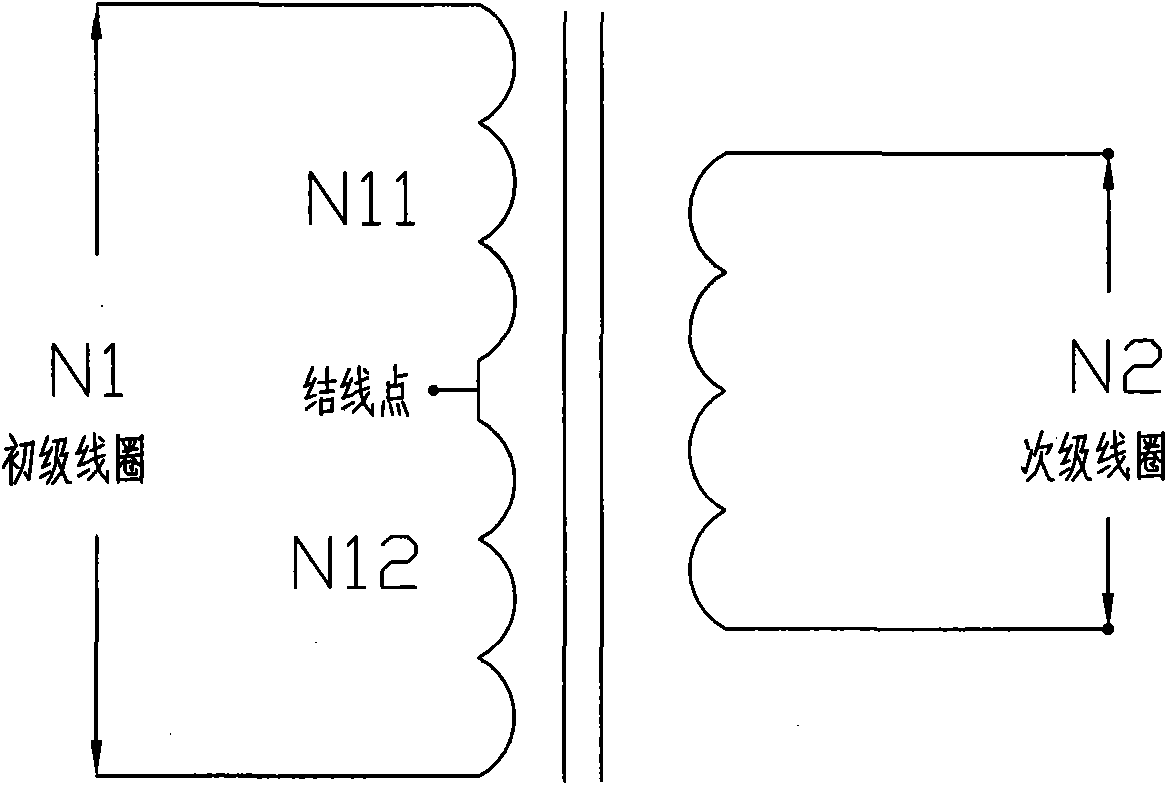

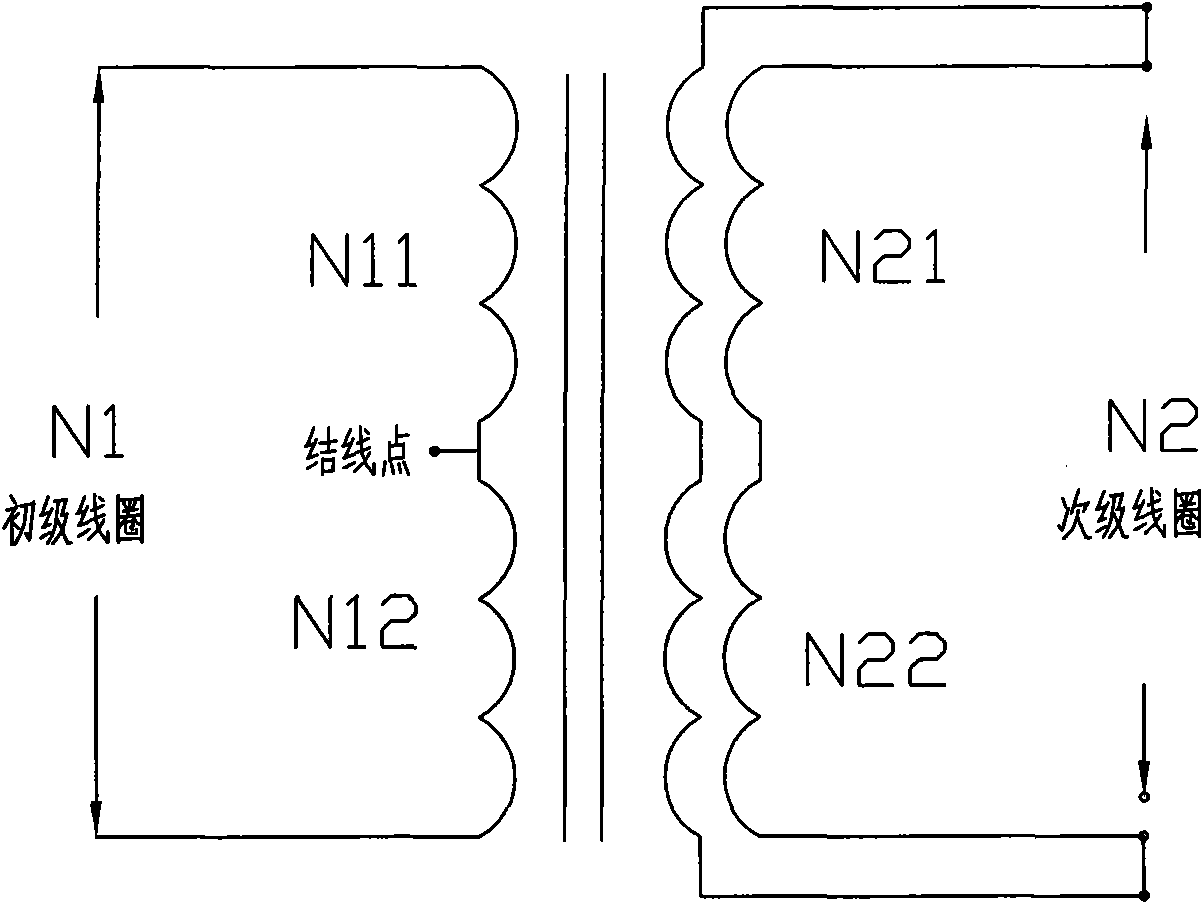

[0022] The present invention is a new winding method of a high-frequency transformer coil. First, the number of turns (number of turns) of the primary and secondary coils N1 and N2 is divided into several equal parts; One equal number of coil turns of the primary coil is then wound around one equal number of turns of the secondary coil, so that each equalized primary and secondary coil is wound crosswise until all the equalized primary and secondary coils are wound. Coil; the secondary coil is divided and wound with two or more strands of coil, and the number of parallel wound strands of the secondary coil is calculated according to the current to be passed. Through the cross-winding of the primary and secondary coils, the inductance between the coils can be improved, and the conversion efficiency is greatly improved compared with the transformer produced by the current winding method.

[0023] The number of turns of the primary and secondary coils N1 and N2 can be divided int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com