Power clamping static protection circuit

An electrostatic protection and power supply technology, applied in the field of power supply clamp electrostatic protection circuit, can solve the problem of not being able to help the input and output unit electrostatic current discharge well, and achieve the effect of saving area and improving electrostatic protection capability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings.

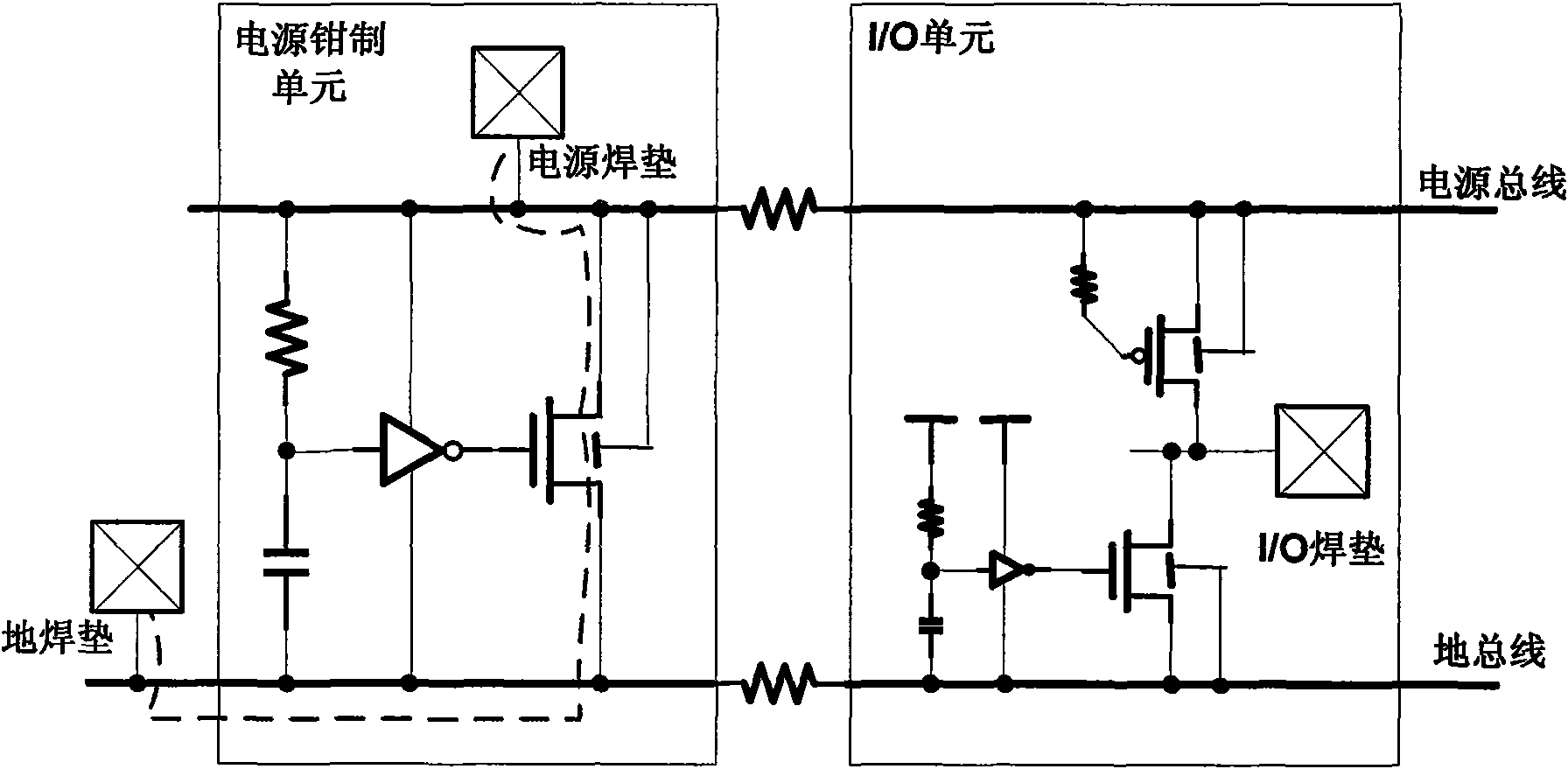

[0012] figure 1 is a schematic diagram of a previous power supply clamping unit circuit. The circuit in the power supply clamping unit is an independent power supply electrostatic protection clamping circuit. figure 1 The curve formed by the dotted line segment in the figure shows the path of the electrostatic current discharge when the electrostatic discharge test (ESD zapping) occurs between the VDD Pad and the GND Pad. It will pass through the electrostatic protection circuit in the input / output unit (I / O unit).

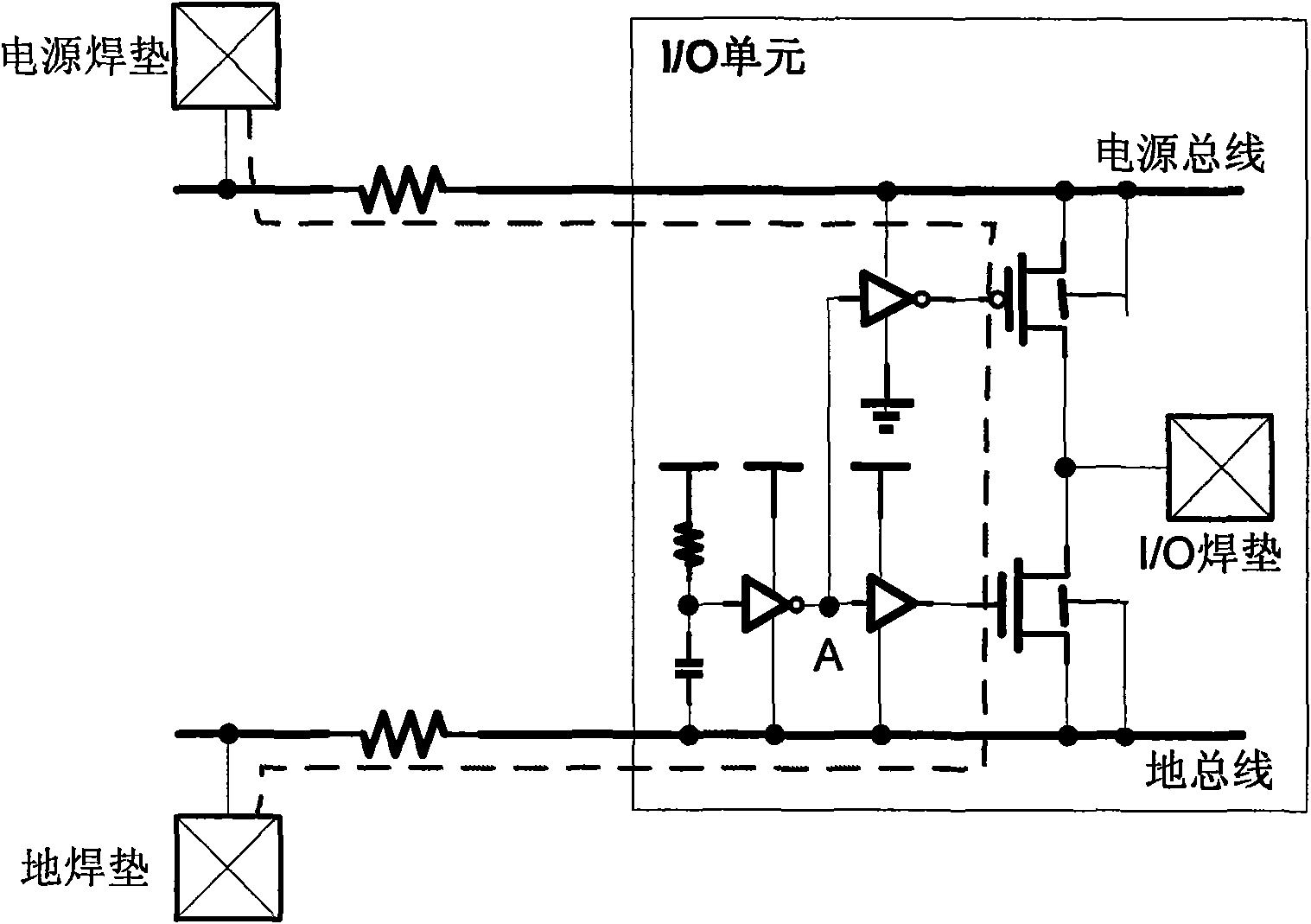

[0013] figure 2 It is a schematic diagram of the source clamping electrostatic protection circuit of the present invention. In the I / O unit, the original ESDNMOS trigger circuit is modified. The output (point A) of the original starting circuit is output to the gate of the NMOS through the forward buffer, and output to the gate of the PMOS ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com