Lubricating oil composition

A technology of lubricating oil composition and compound, applied in lubricating composition, petroleum industry, additives, etc., can solve problems such as inability to precisely control hydraulic equipment, hydraulic cylinder vibration, abnormal noise, etc., achieve low friction coefficient, precise control, reduce The effect of frictional losses

Inactive Publication Date: 2009-10-28

SHOWA SHELL SEKIYU KK

View PDF1 Cites 15 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In addition, although hydraulic equipment is generally used in construction machinery, etc., if the friction coefficient of lubricating oil used for hydraulic oil is high, micro-stick-slip occurs in the sliding area of the reciprocating module of the hydraulic cylinder, causing problems such as hydraulic Phenomena such as cylinder vibration, vibration, sharp sound or abnormal noise, making it impossible to accurately control hydraulic equipment

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1~19

[0101] Examples 1-19, Comparative Examples 1-5

[0102] Lubricating oil compositions of Examples 1 to 19 and Comparative Examples 1 to 5 were prepared with the compositions shown in Tables 1 to 5 using the materials of the above compositions.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Coefficient of friction | aaaaa | aaaaa |

Login to View More

Abstract

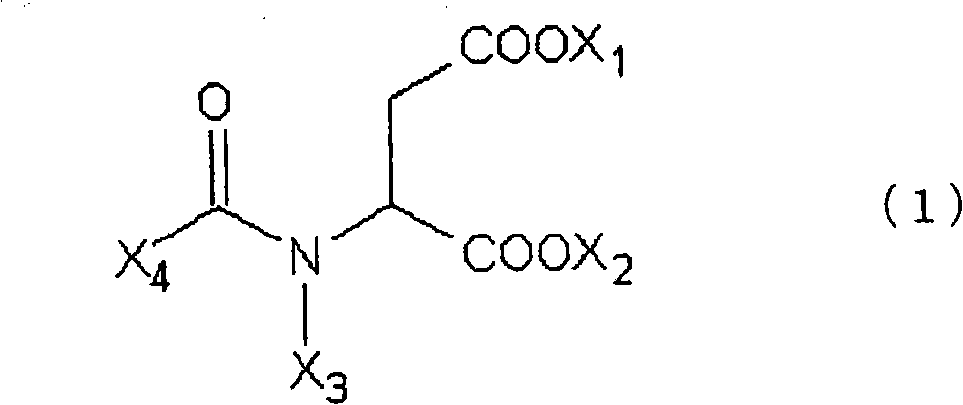

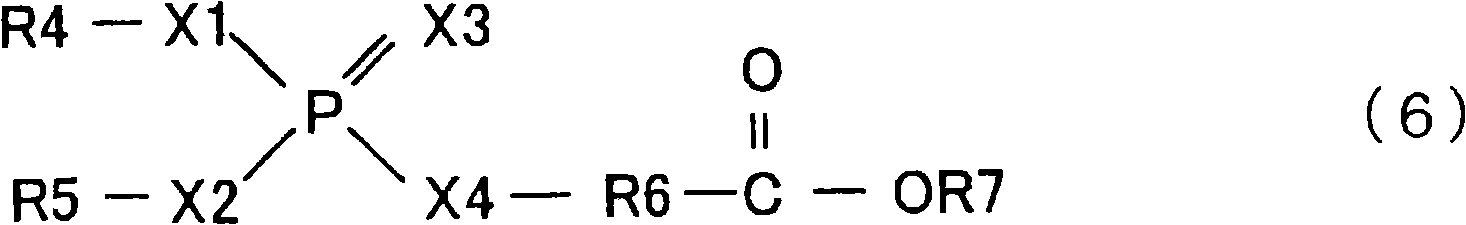

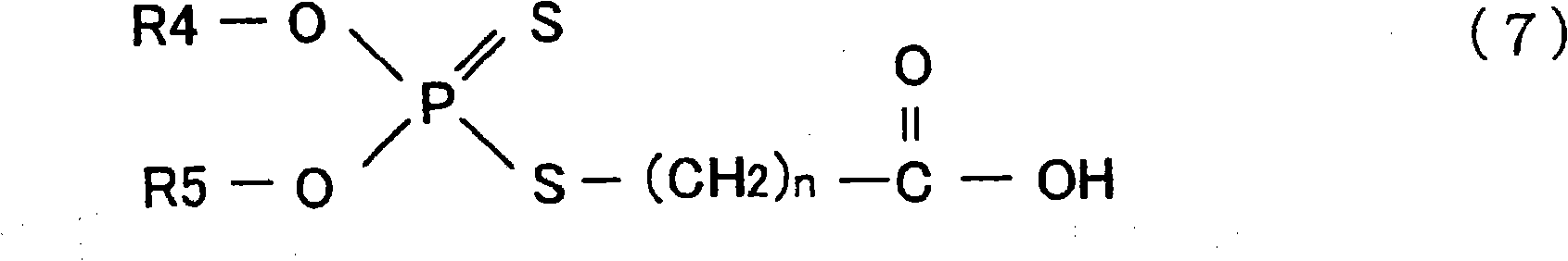

The present invention provides a lubricating oil composition comprising a base oil, an aspartic acid derivative and an aliphatic amine compound. The lubricating oil composition is ideal as an industrial lubricating oil such as for example for a hydraulic working oil in hydraulic equipment. Primary amine, secondary amine, diamine, and / or tertiary amines may be employed for the aliphatic amine compound.

Description

technical field [0001] The present invention relates to lubricating oil compositions, especially lubricating oil compositions for use as industrial lubricating oils, especially for use as machine oils, hydraulic oils, turbine oils, compressor oils, gear oils, sliding surface oils, bearing oils Or the lubricating oil composition of the calibration oil. Background technique [0002] Lubricating oils used in mechanical equipment require the necessary rust resistance to maintain their performance. The reasons for this include the following: the temperature of the lubricating oil in the oil tank in mechanical equipment is raised and lowered depending on the conditions of use, which may cause condensed water to mix with the lubricating oil in the oil tank; Moisture mix. In order to obtain this rust resistance, aspartic acid ester or the like is used. See Japanese Patent Application Laid-Open No. 6-200268. [0003] Also, in recent years, industrial lubricating oil compositions ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C10M141/00C10M141/02C10M141/06C10M169/04C10N30/06C10N30/12

CPCC10N2240/30C10M2203/1025C10M169/04C10M2207/283C10M141/00C10M2223/047C10M2207/12C10M2215/042C10N2240/14C10N2240/02C10M2215/06C10M2207/127C10N2230/12C10N2240/08C10M141/10C10M2215/065C10M2205/0285C10N2230/06C10M141/02C10M2209/084C10N2240/06C10M141/08C10M2229/041C10M2223/04C10M2205/173C10M2207/026C10M141/06C10M2203/1006C10M2215/064C10M2209/105C10M2207/289C10N2240/04C10M2215/08C10M2209/104C10M2215/223C10M2215/04C10M141/12C10M2207/282C10N2030/12C10N2030/06C10N2040/02C10N2040/04C10N2040/06C10N2040/08C10N2040/135C10N2040/30

Inventor 永仮光洋金子弘马场善治

Owner SHOWA SHELL SEKIYU KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com