Semiconductor device and method for manufacturing the same

A manufacturing method and semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, transistors, etc., can solve problems such as hindering and reducing on-resistance, and achieve the effect of alleviating the rise of on-resistance

Inactive Publication Date: 2011-01-05

PANASONIC CORP

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

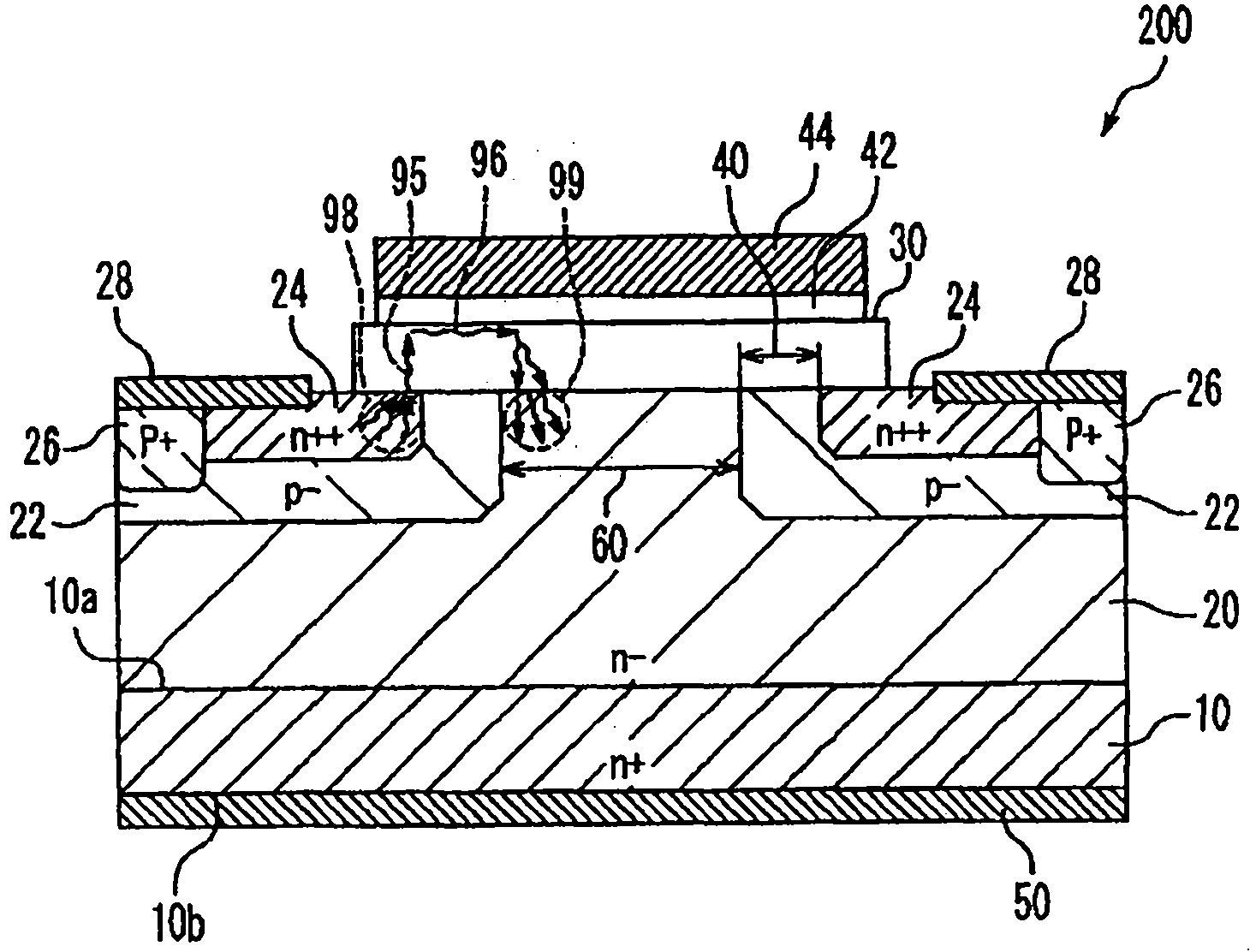

However, the inventors of the present application found that the current may be concentrated in a part of the channel epitaxial layer 105, and the reduction of the on-resistance will be hindered due to the current concentration.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

no. 1 approach

no. 2 approach

no. 3 approach

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

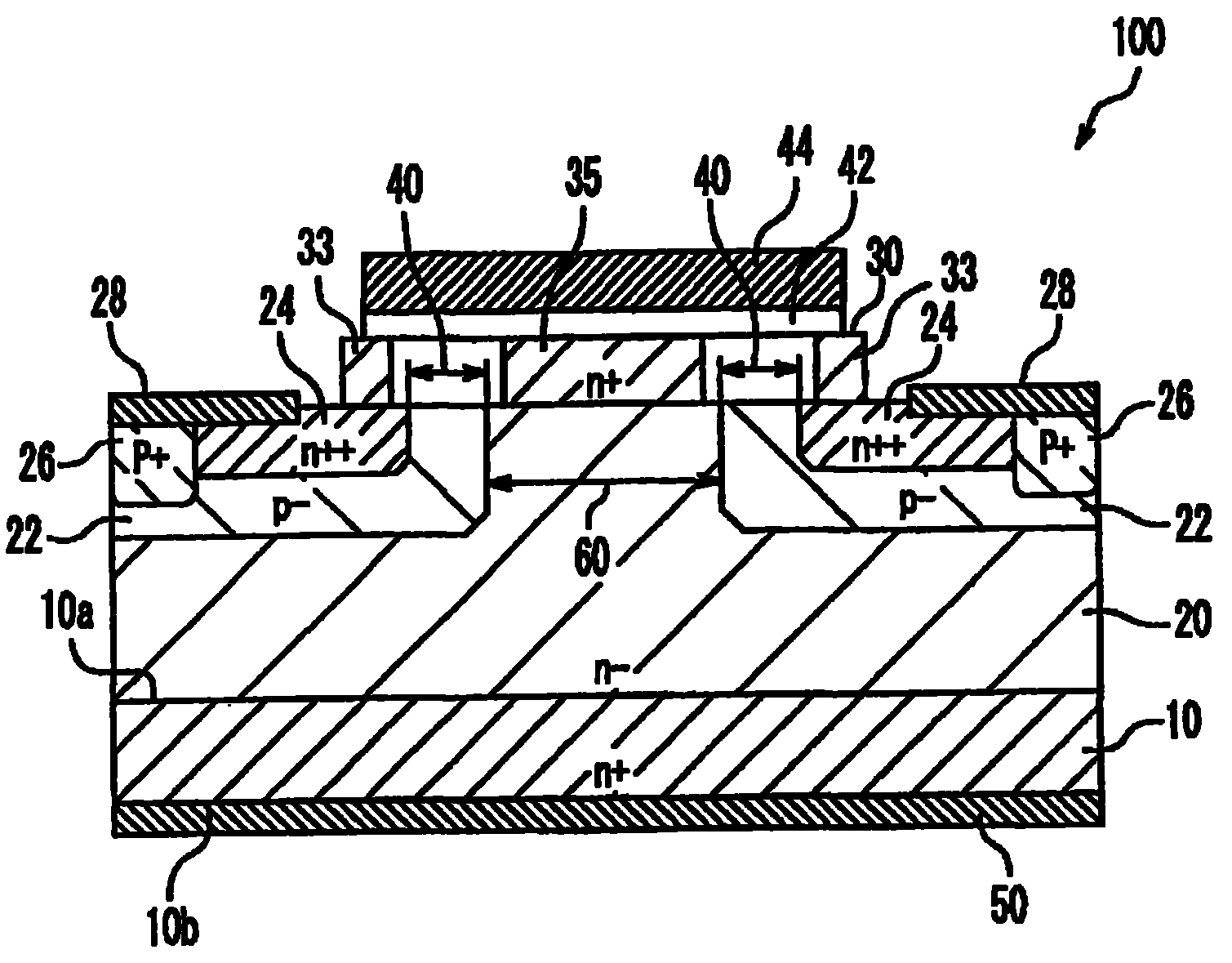

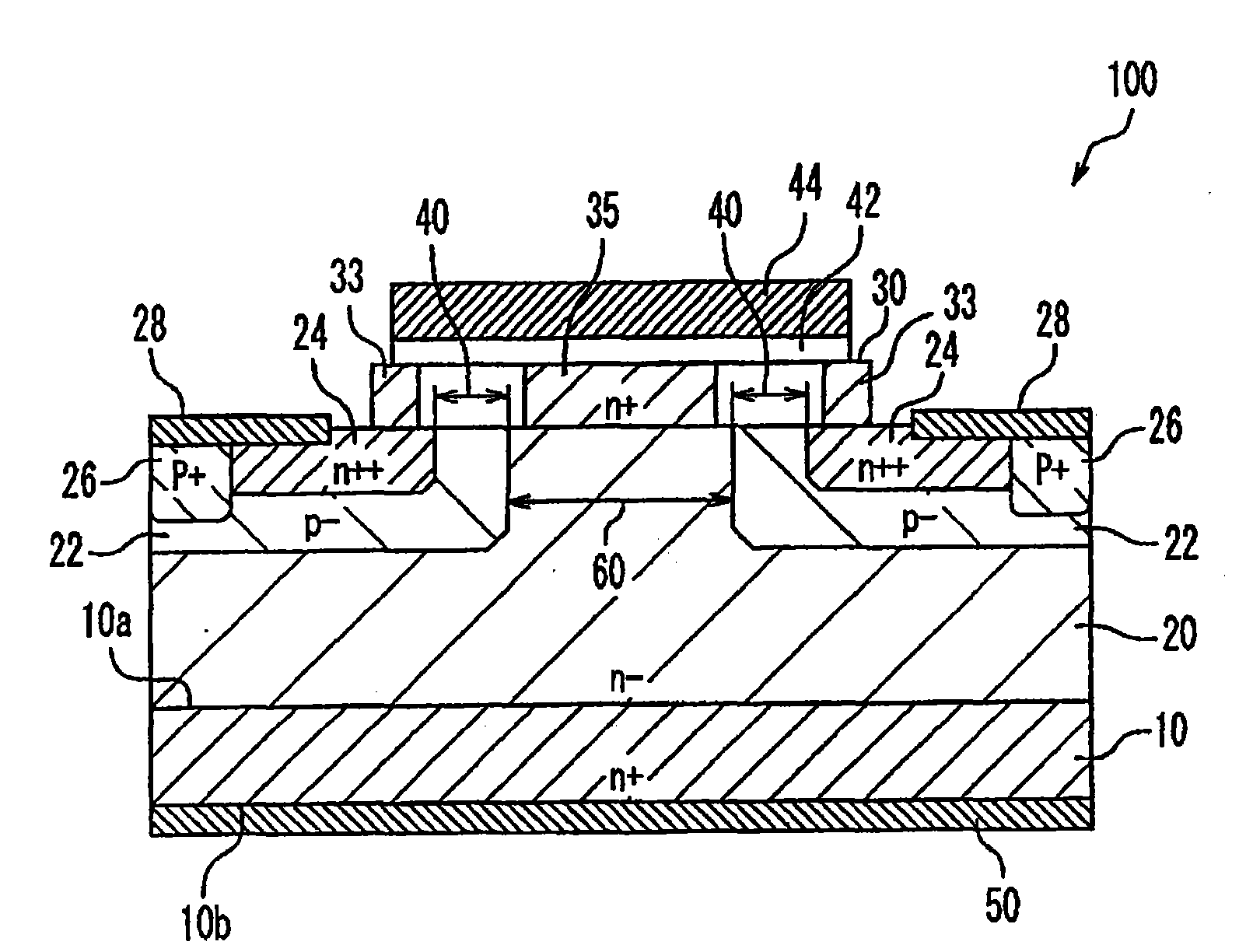

Disclosed is a semiconductor device (100) comprising a semiconductor substrate (10) of a first conductivity type which is composed of silicon carbide, a silicon carbide epitaxial layer (20) of the first conductivity type formed on a major surface (10a) of the semiconductor substrate (10), a well region (22) of a second conductivity type formed in a part of the silicon carbide epitaxial layer (20),and a source region (24) of the first conductivity type formed in a part of the well region (22). A channel epitaxial layer (30) composed of silicon carbide is formed on the silicon carbide epitaxiallayer (20), the well region (22) and the source region (24), and a part of the channel epitaxial layer (30) located on the well region (22) functions as a channel region (40). A dopant of the first conductivity type is implanted into portions (33, 35) of the channel epitaxial layer (30), namely portions other than the channel region (40).

Description

Semiconductor device and manufacturing method thereof technical field The present invention relates to a semiconductor device and a manufacturing method thereof. In particular, the invention relates to a power semiconductor device made of silicon carbide for high withstand voltage and high current. Background technique A power semiconductor device is a semiconductor element used for passing a large current at a high withstand voltage, and preferably has low loss. Existing power semiconductor devices mainly use silicon (Si) substrates, but power semiconductor devices using silicon carbide (SiC) substrates have attracted attention in recent years and have been continuously developed (for example, refer to Patent Documents 1 to 6 Wait). Because silicon carbide (SiC) has a one-digit higher insulation breakdown voltage than silicon (Si), it has the advantage that even if the depletion layer in the pn junction and Schottky junction is thinner, it can Maintain reverse withsta...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01L29/12H01L21/336H01L27/088H01L21/8234H01L29/78

CPCH01L29/1608H01L29/42368H01L29/7828H01L29/66068H01L29/0847

Inventor 工藤千秋楠本修桥本浩一

Owner PANASONIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com