A kind of MOS field-controlled thyristor based on Schottky diode and its manufacturing method

A technology of Schottky diodes and manufacturing methods, which is applied in the manufacture of diodes, thyristors, semiconductors/solid-state devices, etc., can solve the problems of current concentration, device fatigue damage, and reduce the efficiency of redundant holes, etc., to solve repeated charging and discharging, Effects of alleviating current concentration and reducing off-time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

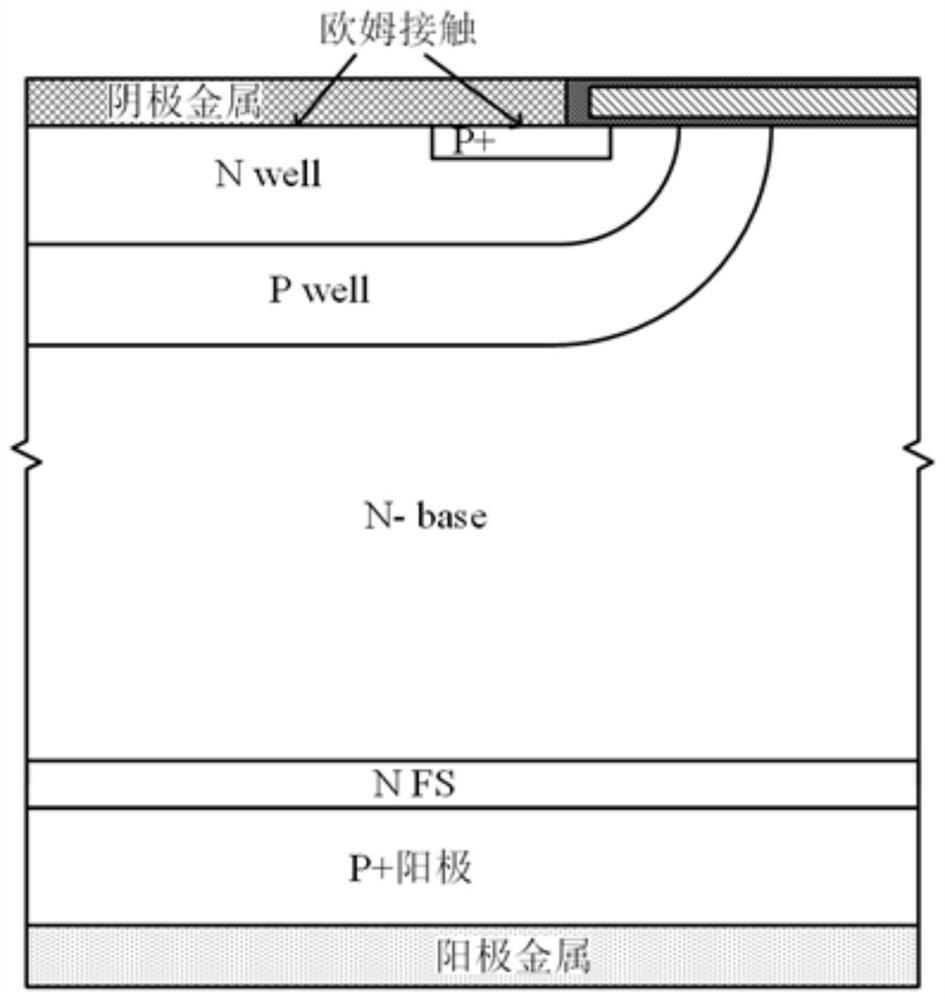

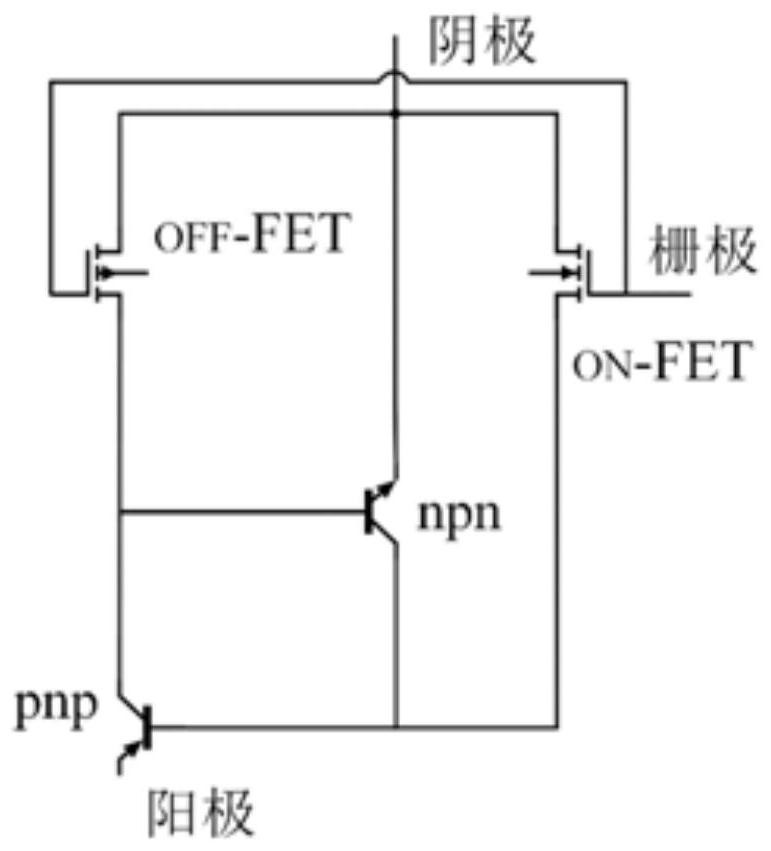

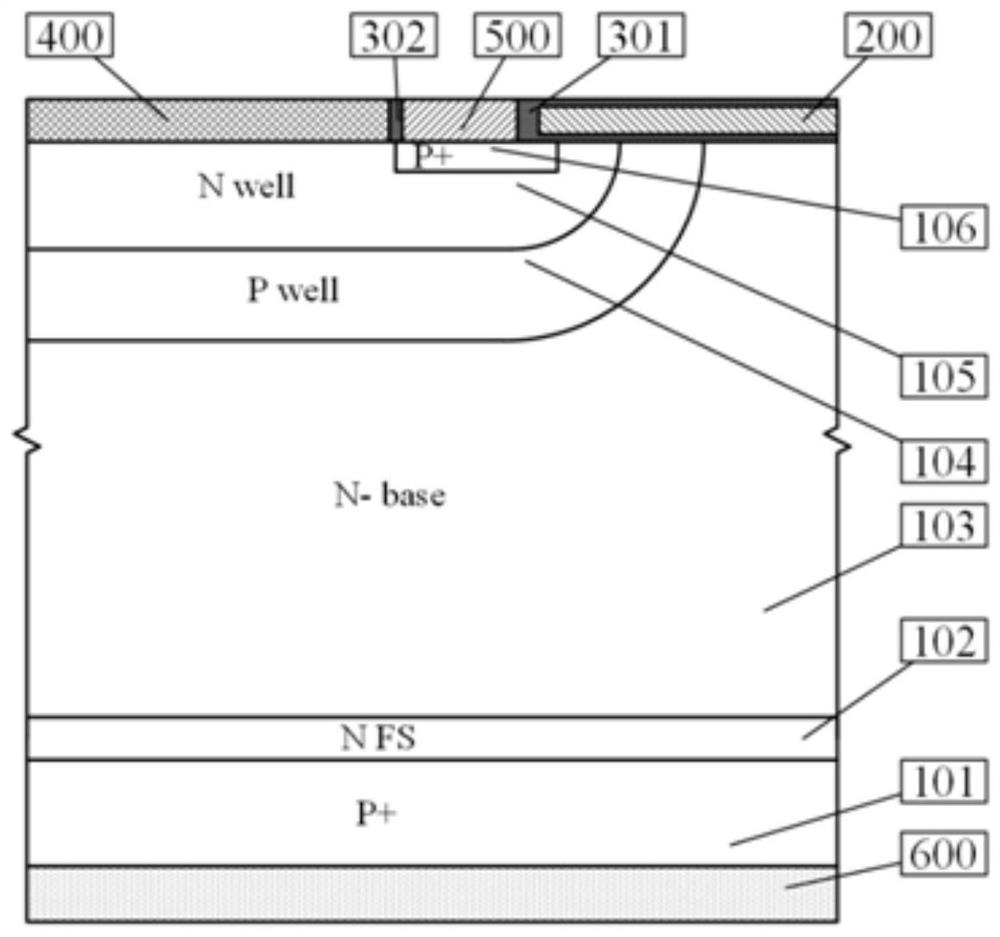

[0055] Taking the traditional MCT structure with a withstand voltage of 1200V and the MCT structure of the present invention as an example for simulation comparison, it is intuitively shown that the present invention has well solved the problem of the conventional MCT turning off the pulse circuit for a long time. MCT structure schematic diagram of the present invention is as image 3 As shown, the equivalent circuit diagram is shown in Figure 4 shown. In order to rule out some potential influencing factors, the simulation uses Figure 5 As shown in the traditional MCT structure, its equivalent circuit is as figure 2 shown. The half-cell width of the two MCTs is 14 μm, and the doping concentration of the P+ region is 4×19 cm -3 , except for the difference in the contact type of the cathode metal, the rest of the structural parameters are the same. In the MCT of the present invention, the work function of the second cathode metal 500 in contact with the P+ region is 4.8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com