A lateral bipolar power semiconductor device and a manufacturing method thereof

A power device and semiconductor technology, applied in the field of bipolar semiconductor power devices and their preparation, can solve the problems of increasing the turn-off time of the device, increasing the turn-off loss and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

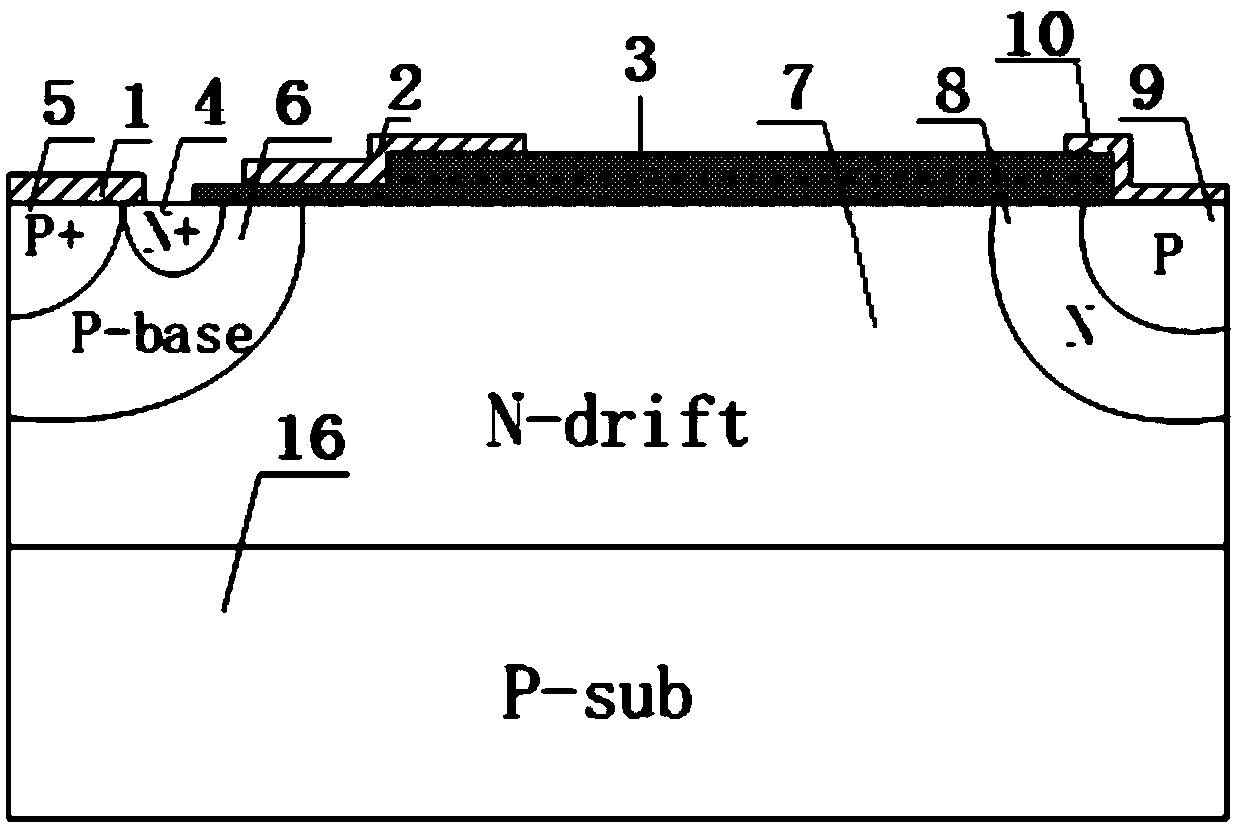

[0095] This embodiment provides a MOS control anode IGBT device, the cell structure of which is as follows figure 2 As shown, it includes an anode structure, a drift region structure, a cathode structure and a control gate structure located above the P+ substrate 116; wherein, the drift region structure is located on the upper surface of the P+ substrate 116, and the drift region structure includes an N-type drift region 107; The anode structure is located on one side of the top layer of the N-type drift region 107, and the anode structure includes an N-type buffer layer 108, a P-type anode region 109 located on the top layer of the N-type buffer layer 108, and an anode metal drawn from the P-type anode region 109 118; the cathode structure is located on the other side of the top layer of the N-type drift region 107, and the cathode structure includes a P-type body region 106, a P+ emitter region 105, an N+ emitter region 104 and a cathode metal 101; the P-type body region 106...

Embodiment 2

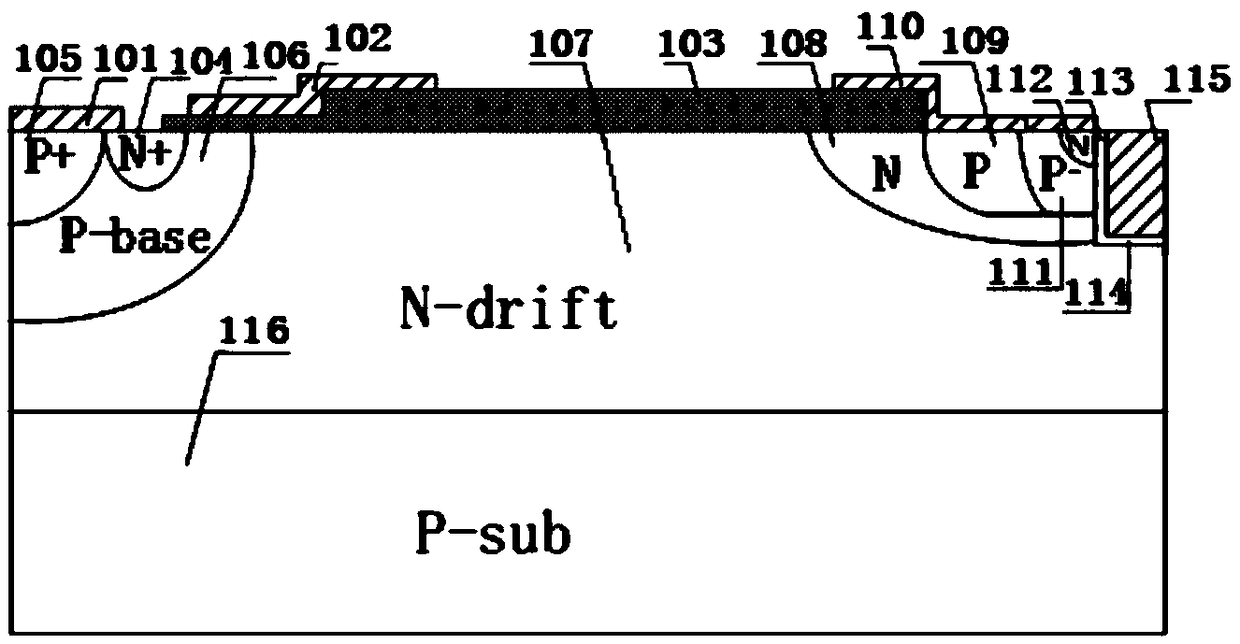

[0098] This embodiment provides a MOS control anode IGBT device, the cell structure of which is as follows image 3 As shown, the difference from Embodiment 1 is that the thickness of the second anode trench gate dielectric layer 114 in the anode trench gate structure is greater than the thickness of the first anode trench gate dielectric layer 113, specifically, the first anode trench gate The thickness of dielectric layer 113 is about The thickness of the second anode trench gate dielectric layer 114 is about The purpose of this design is to reduce the parasitic capacitance of the anode trench gate electrode while controlling the turn-on voltage of the anode trench gate, thereby reducing the adverse effect of the parasitic parameters of the anode MOS structure on the IGBT device parameters.

Embodiment 3

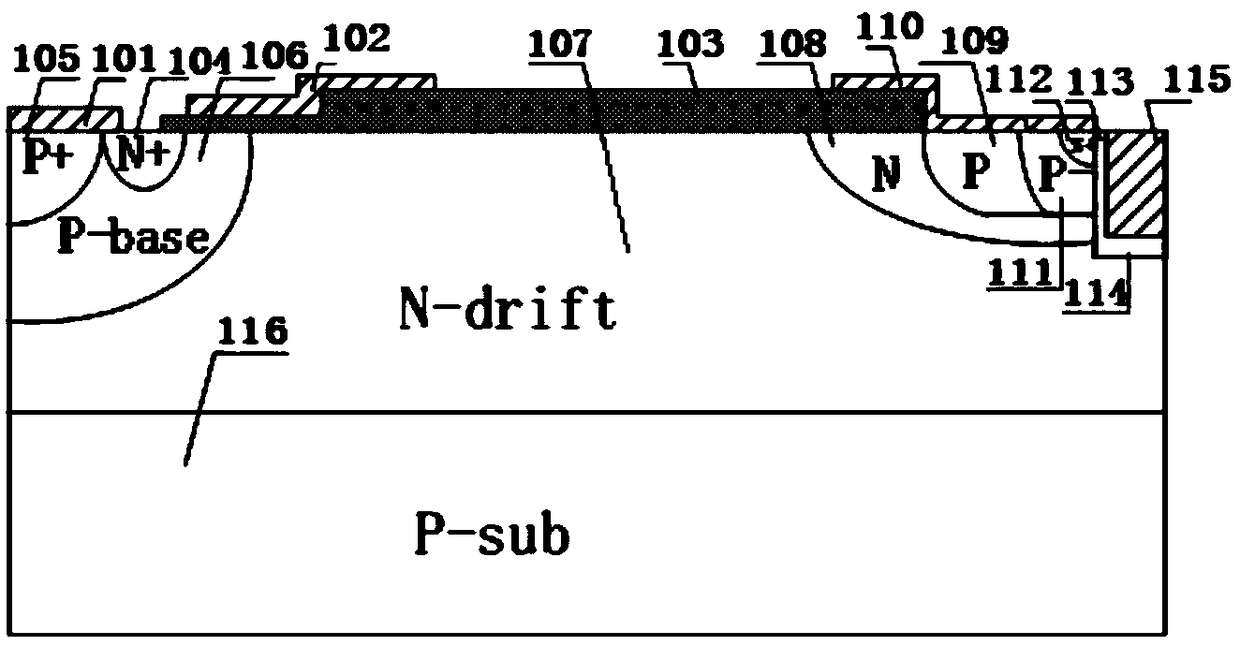

[0100] This embodiment provides a MOS control anode IGBT device, the cell structure of which is as follows Figure 4 As shown, the difference from Embodiment 1 is that the N+ source region 112 in the anode MOS structure is replaced with a P- base region 111 . Since the concentration of the P-base region 111 is lower than that of the P-type anode region 109, when the device is working, the anode trench gate controls the channel inversion on the side, thereby achieving the effect of bypassing the anode diode. At this time, the P-type anode region 109 forms an ohmic contact with the anode metal 110 , and the P-base region 111 forms a Schottky contact with the anode metal 110 .

[0101] When the device is working, the Schottky junction formed by the anode metal 110 and the P-base region 111 is reversely biased. When the control gate structure forms a conductive channel, the carriers passing through the channel of the control gate structure are reversely Under the action of the pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com