Planar silicon carbide reverse-blocking MOSFET device and preparation method thereof

A silicon carbide, planar technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., to achieve the effects of large forward and reverse symmetrical withstand voltage, reduced leakage current, and large forward withstand voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

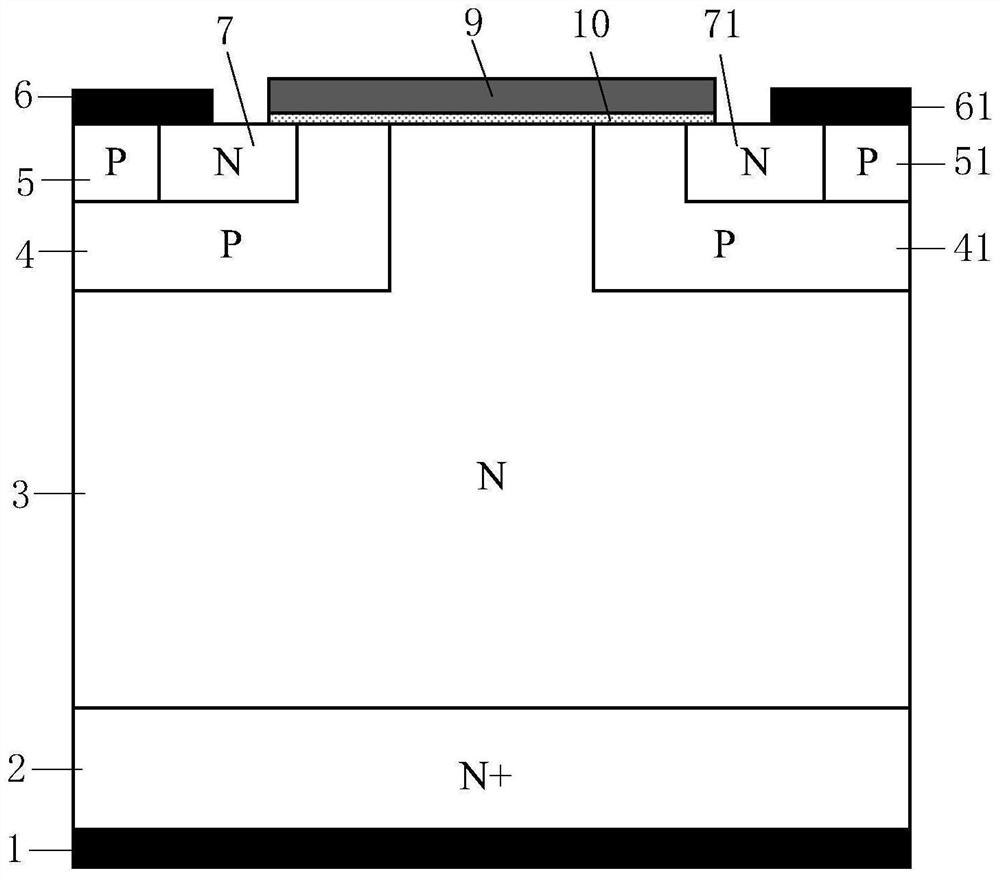

[0077] A reverse-resistance silicon carbide MOSFET, its cell structure is as follows figure 2 As shown, it includes: a back drain metal 1, a second N-type silicon carbide buffer layer 21, an N-type silicon carbide epitaxial layer 3, and a first N-type silicon carbide buffer layer 11 stacked in sequence from bottom to top; The N-type silicon carbide buffer layer 11 has a first P-type silicon carbide base region 4 and a second P-type silicon carbide base region 41; the lower part of the first N-type silicon carbide buffer layer 11 is in contact with the N-type silicon carbide epitaxial layer 3 , the upper part of the first N-type silicon carbide buffer layer 11 separates the first P-type silicon carbide base region 4 and the second P-type silicon carbide base region 41; the first P-type silicon carbide base region 4 has a second A P-type silicon carbide source region 5 and a first N-type silicon carbide source region 7; the first P-type silicon carbide source region 5 is in con...

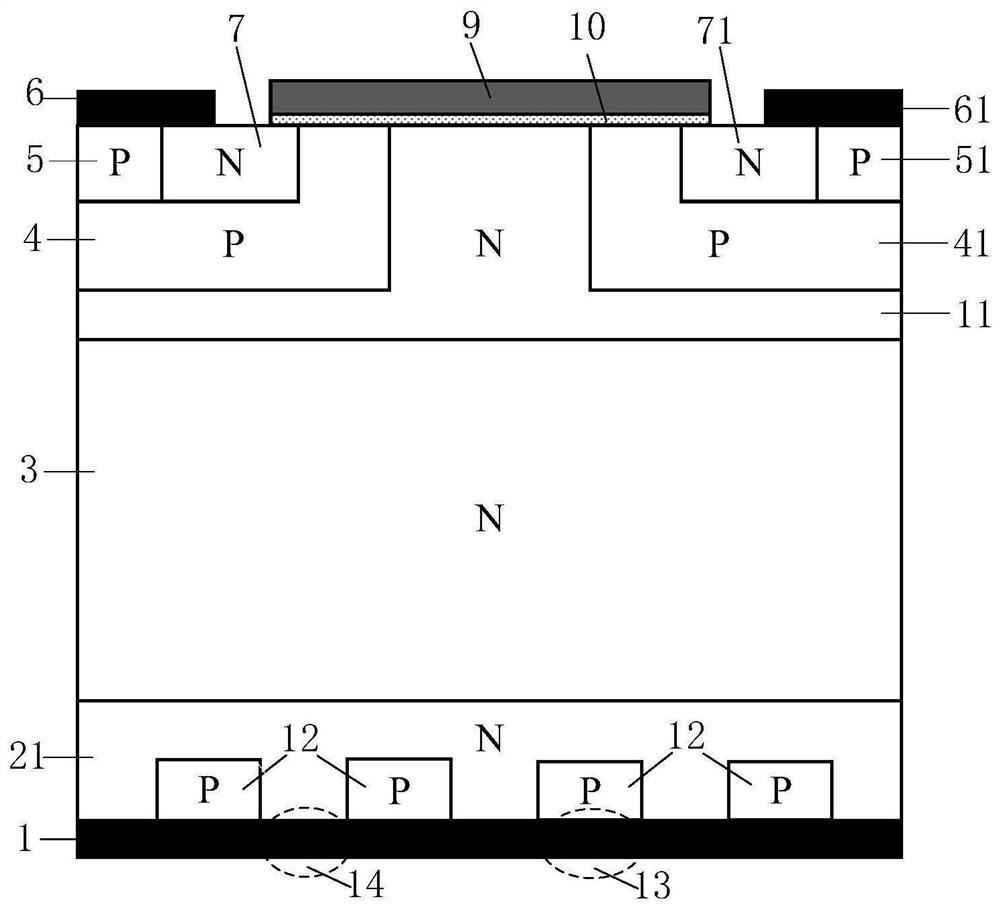

Embodiment 2

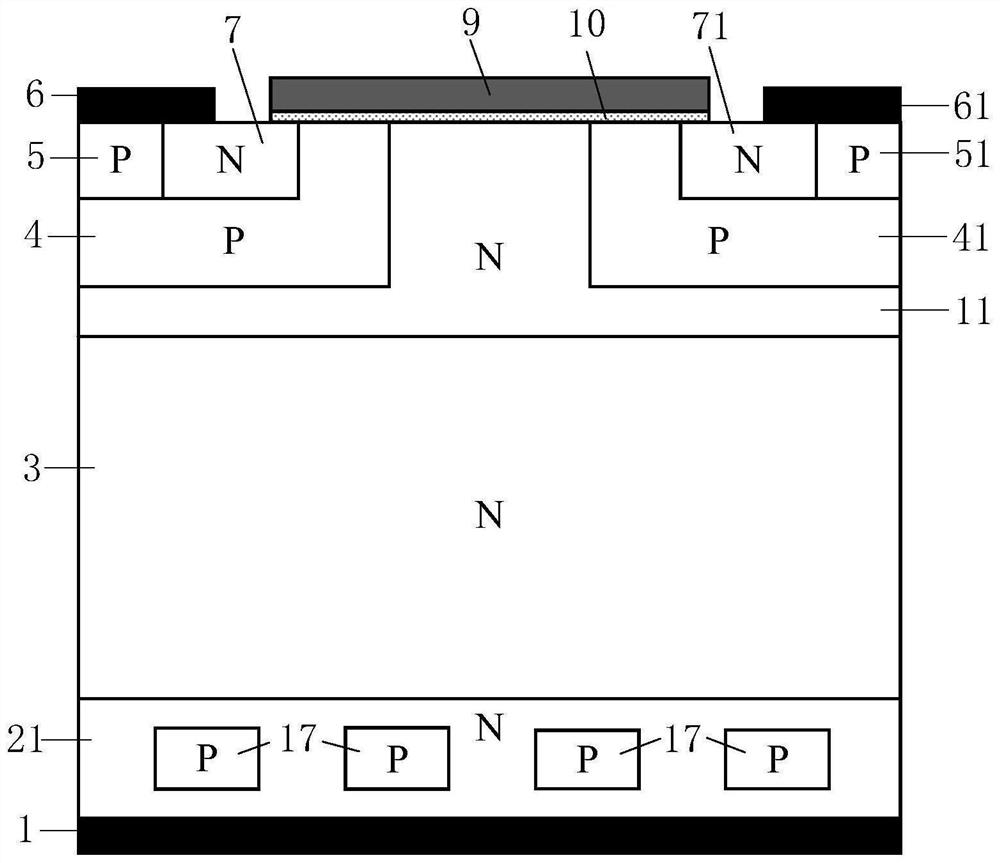

[0093] A reverse-resistance silicon carbide MOSFET, its cell structure is as follows image 3 As shown, the difference between this embodiment and Embodiment 1 is that: the second N-type silicon carbide buffer layer 21 has a P-type floating region 17 that is not connected; There is no contact between them, completely floating in the second N-type silicon carbide buffer layer 21 ; a Schottky contact is formed between the second N-type silicon carbide buffer layer 21 and the back drain metal 1 .

[0094] Preferably, all silicon carbide materials are replaced with gallium nitride, gallium oxide, boron nitride, and silicon materials.

[0095] This embodiment also provides a method for preparing a planar silicon carbide reverse resistance MOSFET device, including the following preparation steps:

[0096] Step 1: using an epitaxial process to prepare a second N-type silicon carbide buffer layer 21 on the surface of the N-type silicon carbide substrate 2;

[0097] Step 2: using an ...

Embodiment 3

[0108] A kind of derivation structure of embodiment 1, its cell structure is as Figure 4 shown. In this embodiment, the N-type silicon carbide epitaxial layer 3 in Embodiment 1 is replaced by P pillars 31 and N pillars 32 , and other structures are the same as those in Embodiment 1.

[0109] In this embodiment, a super junction MOSFET structure is formed by introducing P pillars 31 and N pillars 32 . The specific principle is: when the P column 31 and the N column 32 reach the charge balance, the external non-electricity of the entire drift region can be approximately neutral, which makes the concentration and withstand voltage of the drift region relatively independent. This embodiment can ensure that the conduction voltage drop of the device is effectively reduced under the same withstand voltage level, and the performance of the device is improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com