Device for loading and unloading crystal bars

A technology for loading and unloading devices and crystal rods, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of safety, poor reliability, laborious manual operation, and easy damage of crystal rods, so as to improve efficiency, save time, Manpower saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

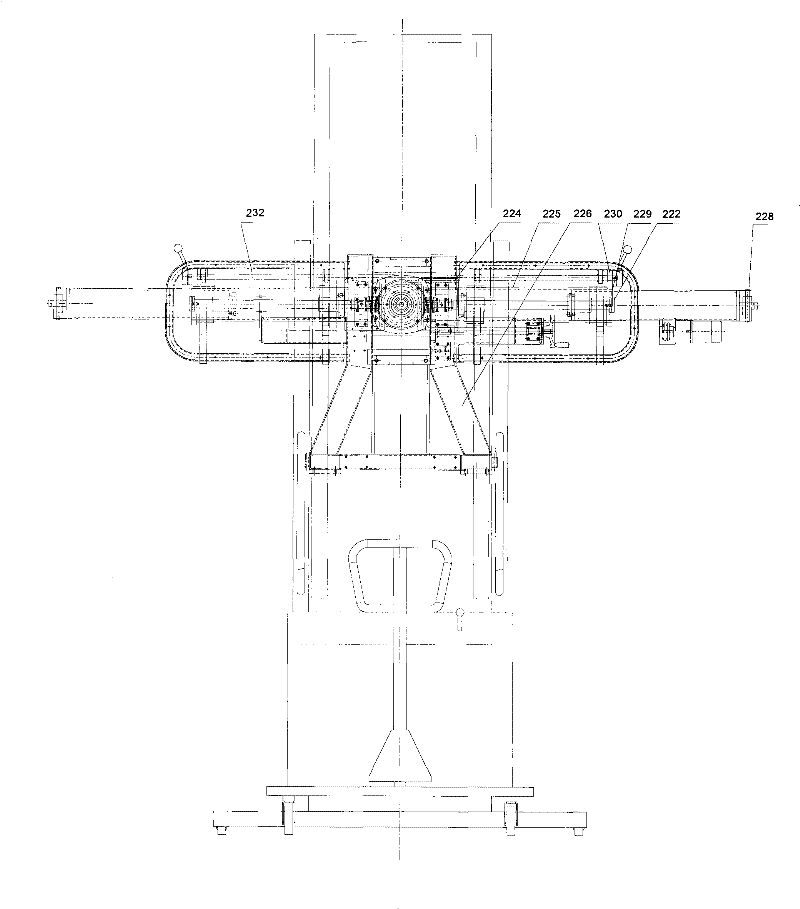

[0055] In order to make the technical means, creative features, goals and effects of the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

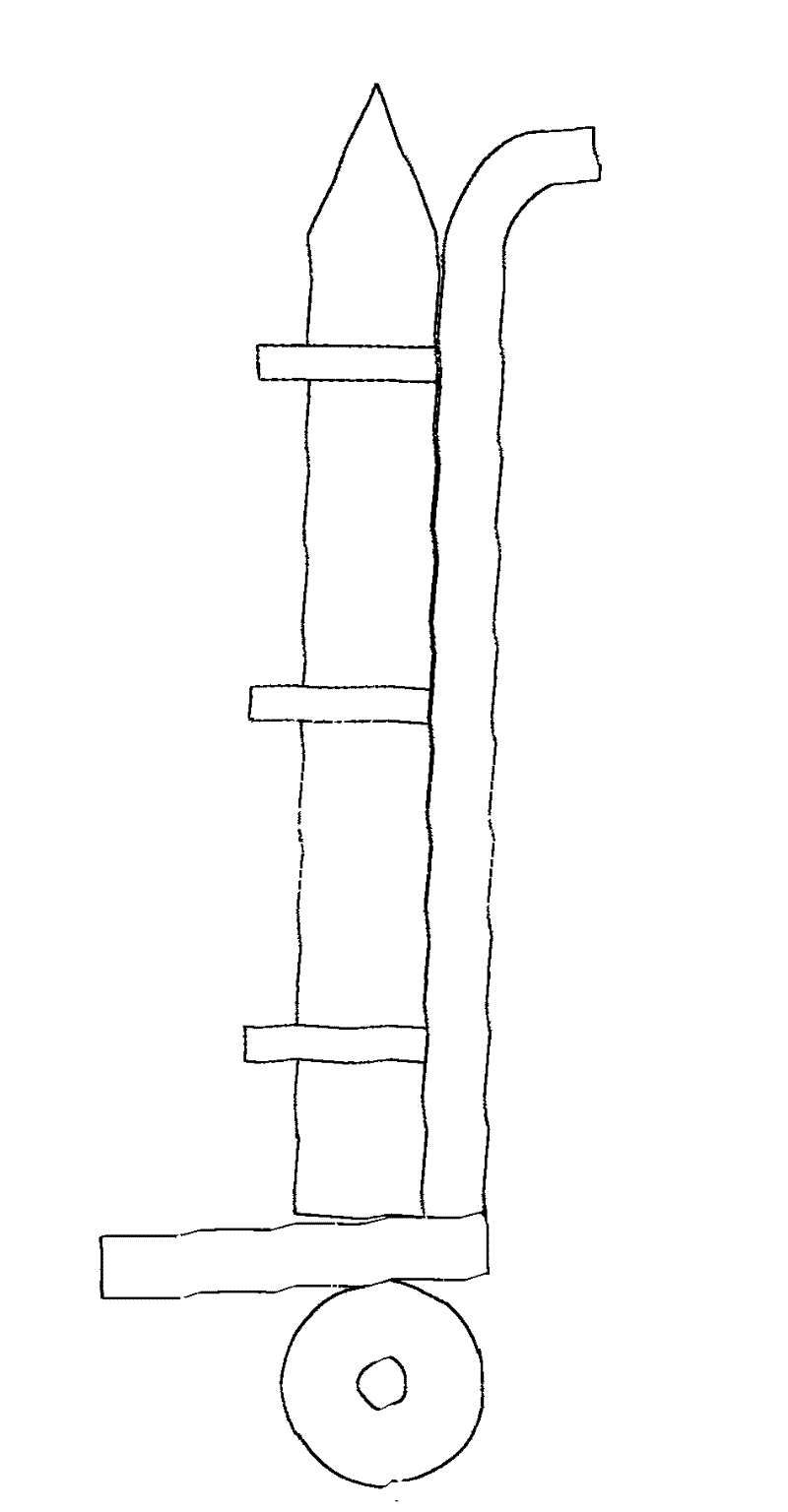

[0056] The crystal ingot loading and unloading device includes a stacker and a console, and the stacker is connected to a crystal ingot clamping device. The stacker adopts the semi-electric stacker 15 of the fixed fork with inserted legs, and the console is the console after 15 of the semi-electric stacker with fixed forks inserted with legs, and the semi-electric stacker with fixed forks with inserted legs 15 is Hangzhou Lifu Special Machinery Co., Ltd. products,

[0057]An operation panel is arranged on the console, and a tilt button (not shown in the drawings) for controlling the movement of the ingot clamping device is arranged on the operation panel, and a lifting motor for hydraulic work is arranged in the semi-electric stacker 15 of the inserted-l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com