Automatic indexing fixture

An automatic indexing and fixture technology, applied in the direction of clamping, manufacturing tools, supports, etc., can solve problems such as inability to achieve accurate indexing, achieve the effects of improving precision, improving production efficiency, and realizing automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

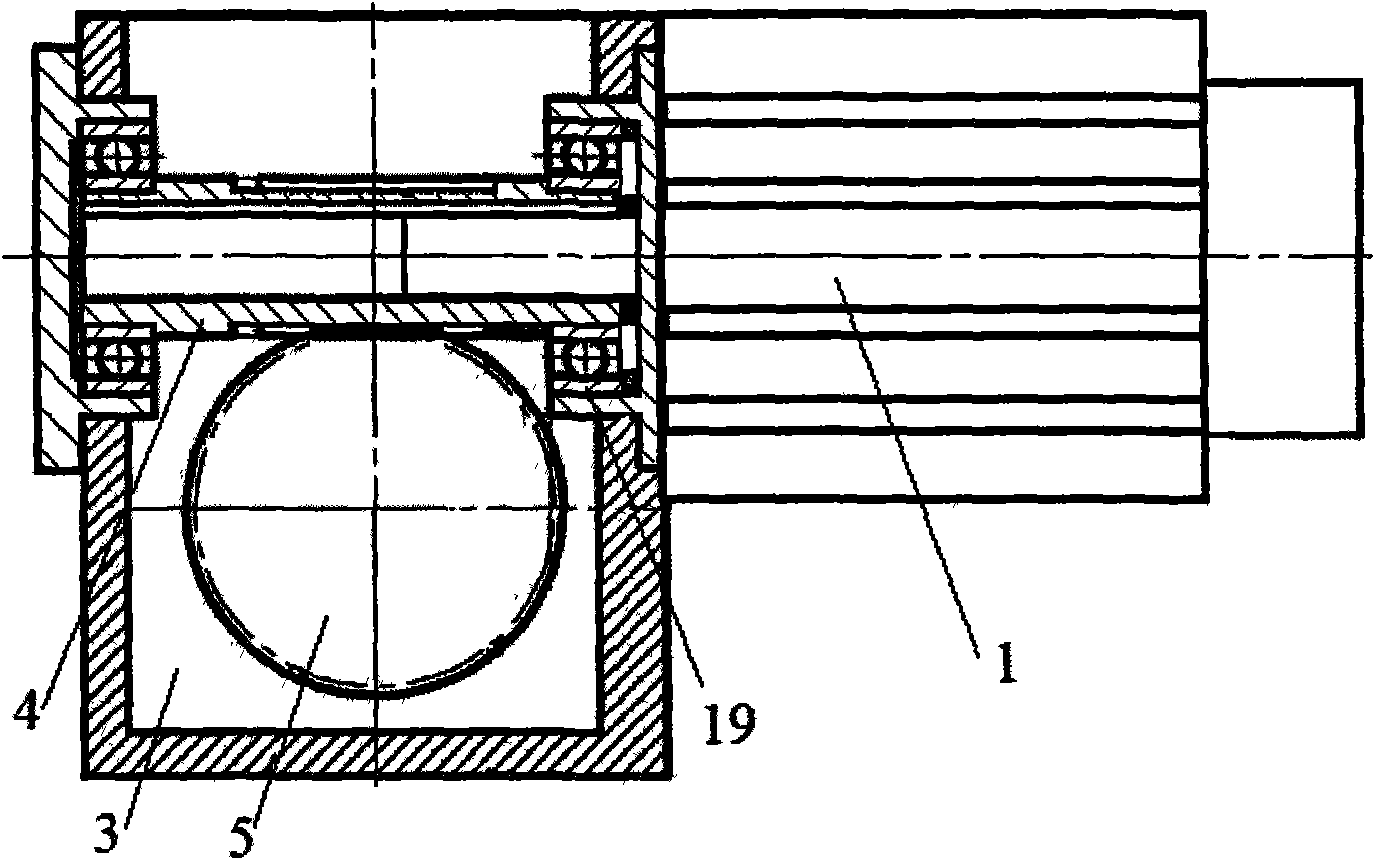

[0031] Such as figure 2 As shown, the driving structure of the worm gear mechanism of the present invention adopts the servo motor 1, and the hole of the worm shaft 4 in the worm gear mechanism is matched with the shaft of the servo motor 1 and is tightly connected.

[0032] Servo motor is a motor that controls the operation of mechanical components in a servo system. It is an auxiliary motor indirect speed change device. Its function is to convert the voltage signal into torque and speed to drive the control object, which can make the control speed and position accuracy very accurate. The encoder is set in the electrical control system of the machine tool, and the accuracy of the servo motor depends on the accuracy (number of lines) of the encoder.

[0033] Using the servo motor as the driving device of the indexing mechanism in the machine tool fixture can improve the indexing accuracy of the indexing device, and can realize the automatic control of the indexing, so that i...

Embodiment 2

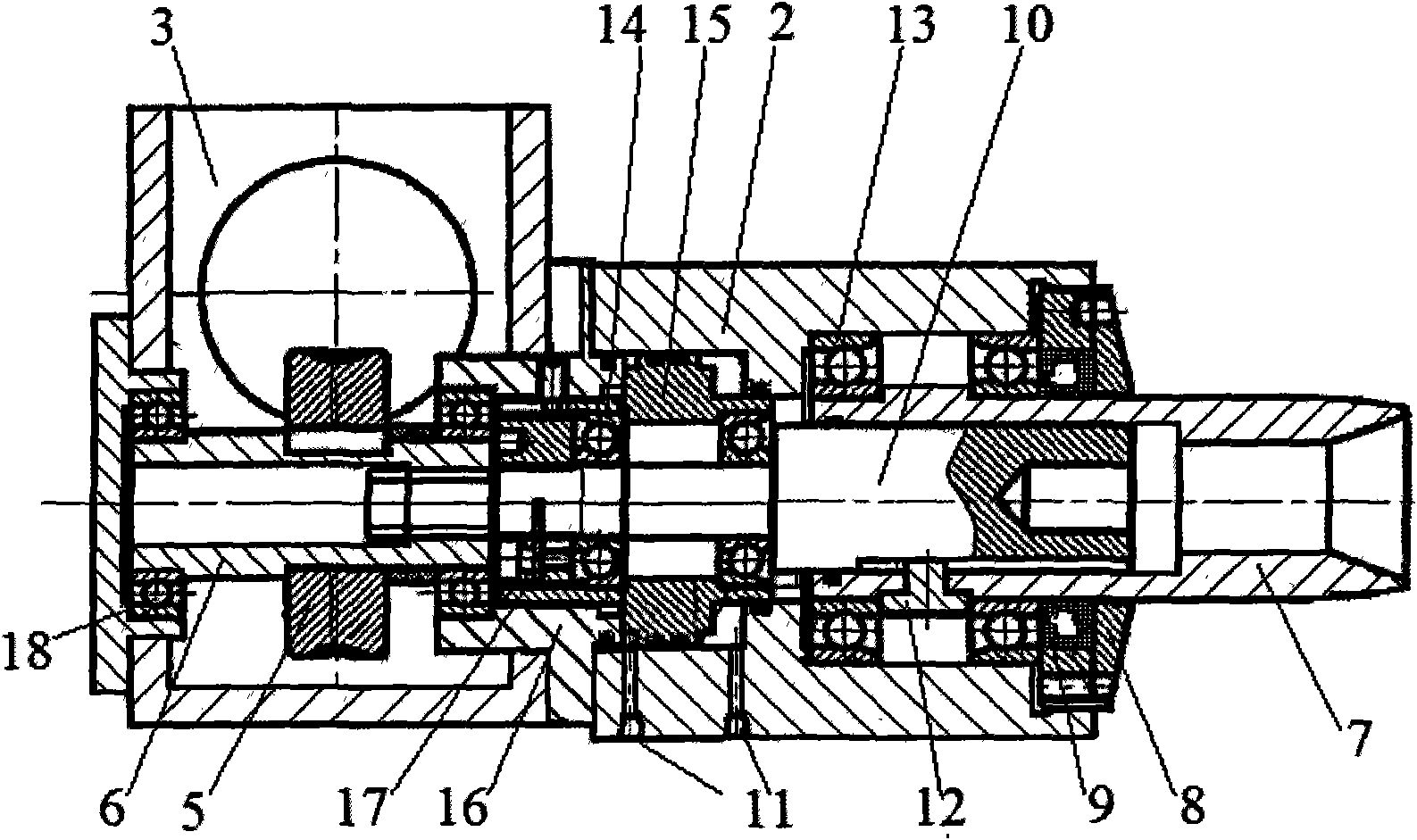

[0035] Such as figure 1 As shown, the pneumatic transmission mechanism of the present invention is provided with a cylinder 2, and the jacket 7 is installed in the hole of the cylinder 2 through a jacket bearing 13. There are two jacket bearings 13, which are distributed at a certain distance along the axial direction of the jacket 7, and play a supporting role on the jacket 7.

[0036] The above-mentioned structure enables relative rotation between the jacket 7 and the cylinder 2 , that is, the jacket 7 can rotate and index in the state of clamping the workpiece, or rotate.

[0037] Cylinder 2 is a fixed part, and its function is to form the execution part driven by air pressure together with cylinder piston 15 described below.

Embodiment 3

[0039] Such as figure 1 As shown, the end of the cylinder 2 according to the present invention is provided with an inner skeleton oil seal 9 tightly sleeved on the outer circle of the jacket 7, and a sealing gland 8 is provided, and the inner skeleton oil seal 9 is fixed by the sealing gland 8 , the sealing gland 8 is fastened on the end of the cylinder 2 .

[0040] The inner frame oil seal 9 and the sealing gland 8 are adopted, and the inner frame oil seal 9 is pressed tightly on the end of the cylinder 2 by the sealing gland 8, so as to play a good sealing effect on the jacket bearing 13.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com