Horizontal planing machine for machining internal hole spline grooves of long shaft parts

A spline groove and horizontal technology, applied in the direction of planer/slotting machine, metal processing equipment, planer, etc., can solve the problems that cannot be implemented, and achieve the effect of convenient loading and unloading, strong versatility and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

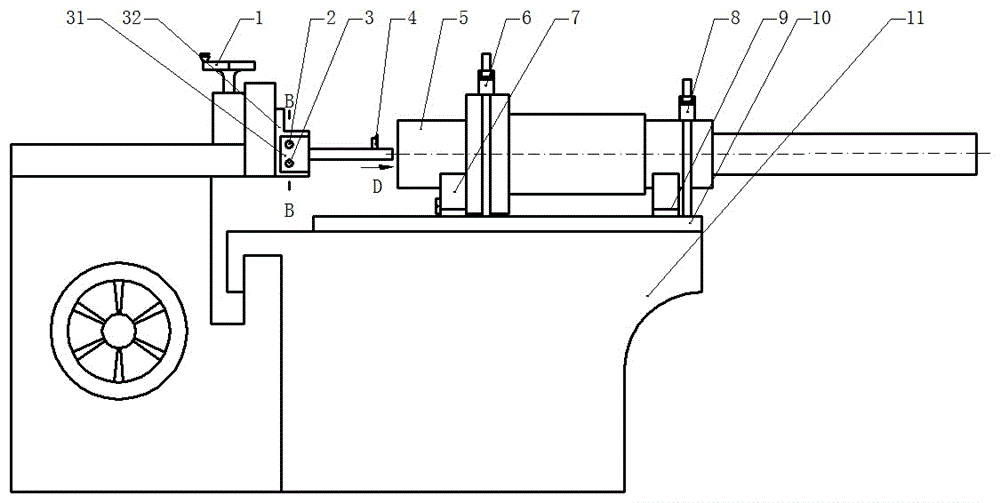

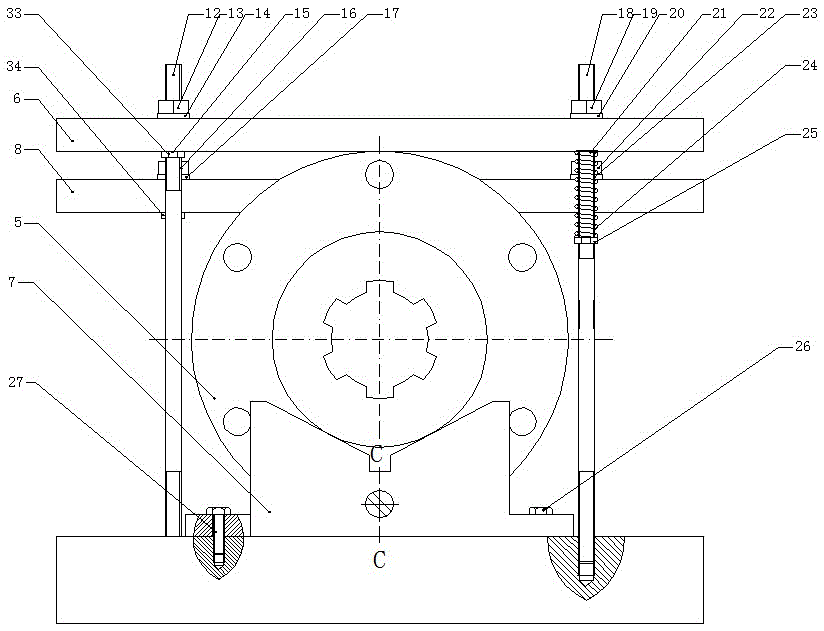

[0024] Take the main shaft 5 of a certain type of reducer as an example below. The main shaft 5 of the reducer is as follows: Figure 9 , Figure 10 As shown, the technical solution of the present invention is further described in conjunction with the accompanying drawings, but it should not be construed as a limitation on the technical solution.

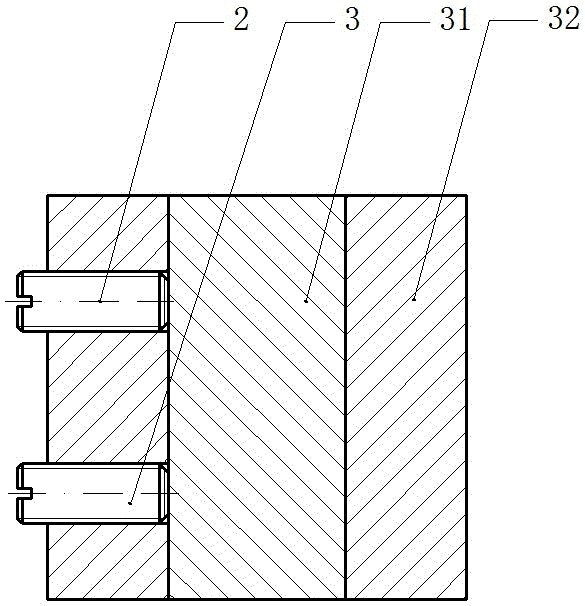

[0025] Such as Figure 1-8 As shown, the horizontal planer includes a horizontal planer body 11, which is characterized in that a cutter and a clamp are installed on the horizontal planer body 11; The left end is horizontally stuck in the slot of the knife holder 32 and fixed by the No. 1 locking screw 2 and the No. 2 locking screw 3 and moves horizontally reciprocatingly. Under the driving of the reciprocating linear motion, the rotating hand wheel 1 adjusts the tool rest 32 to move in the vertical direction and drives the slotting knife 4 to move in the vertical direction to realize the adjustment of the depth of the slotting ke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com