Viscosity reduction heating method for heavy oil recovery in well

A heating method and heavy oil technology, which is applied in the direction of mining fluid, earthwork drilling, wellbore/well parts, etc., can solve the problems of energy waste, high energy consumption, and rising mining costs, and achieve long service life, saving electricity, Labor saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

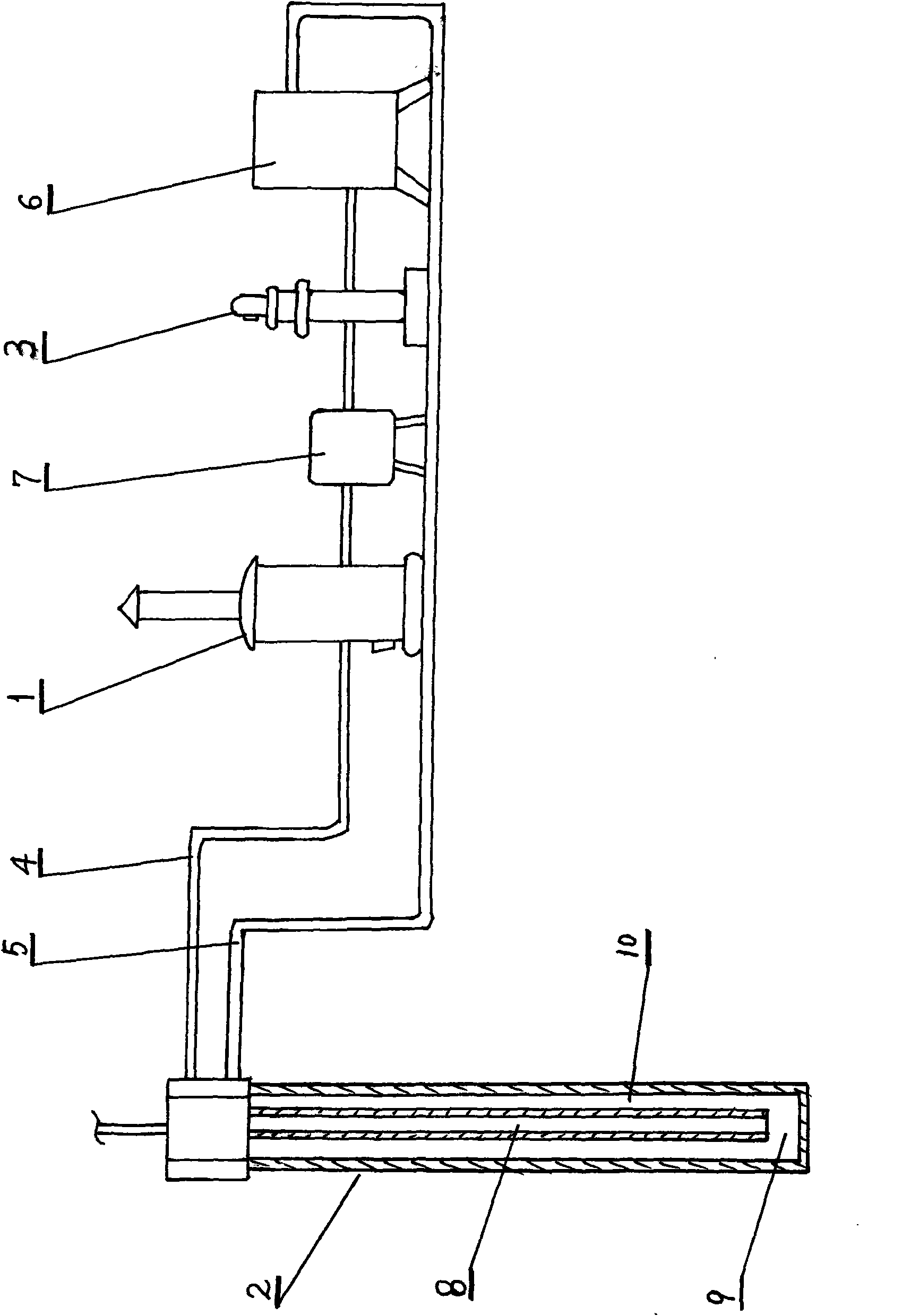

[0010] combine figure 1 Illustrative examples are as follows: the present invention adopts biofuel automatic heater 1 to heat the heat carrier, and adopts double hollow sucker rods 2; Heavy oil circulation heating; the cold water circulated from the double hollow sucker rod 2 enters the liquid storage tank 6 through the return pipe 5, and the high-pressure circulation pump 3 pumps the water in the liquid storage tank 6 into the buffer tank 7 for buffering and gas-water separation, and The biofuel automatically flows into the heater 1 at a high speed for heating, forming a heating system with a closed inner circulation of the heat carrier.

[0011] Driven by the high pressure of the high-pressure circulating pump 3, the heat carrier overcomes the pipe wall friction and flows to the inner hole channel 8 of the double hollow sucker rod 2 at high speed, and then returns to the outside of the double hollow sucker rod 2 after being deposited in the bottom sedimentation chamber 9 Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com