Oil conservator moisture absorber with convenient silica gel replacement

A technology that is easy to replace and oil conservator, applied in the direction of transformer/inductor cooling, etc., can solve the problems of excessively long dimensions, misjudgment of operation monitoring, heavy weight, etc., to save time and maintenance costs, and ensure normal breathing. , the effect of weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

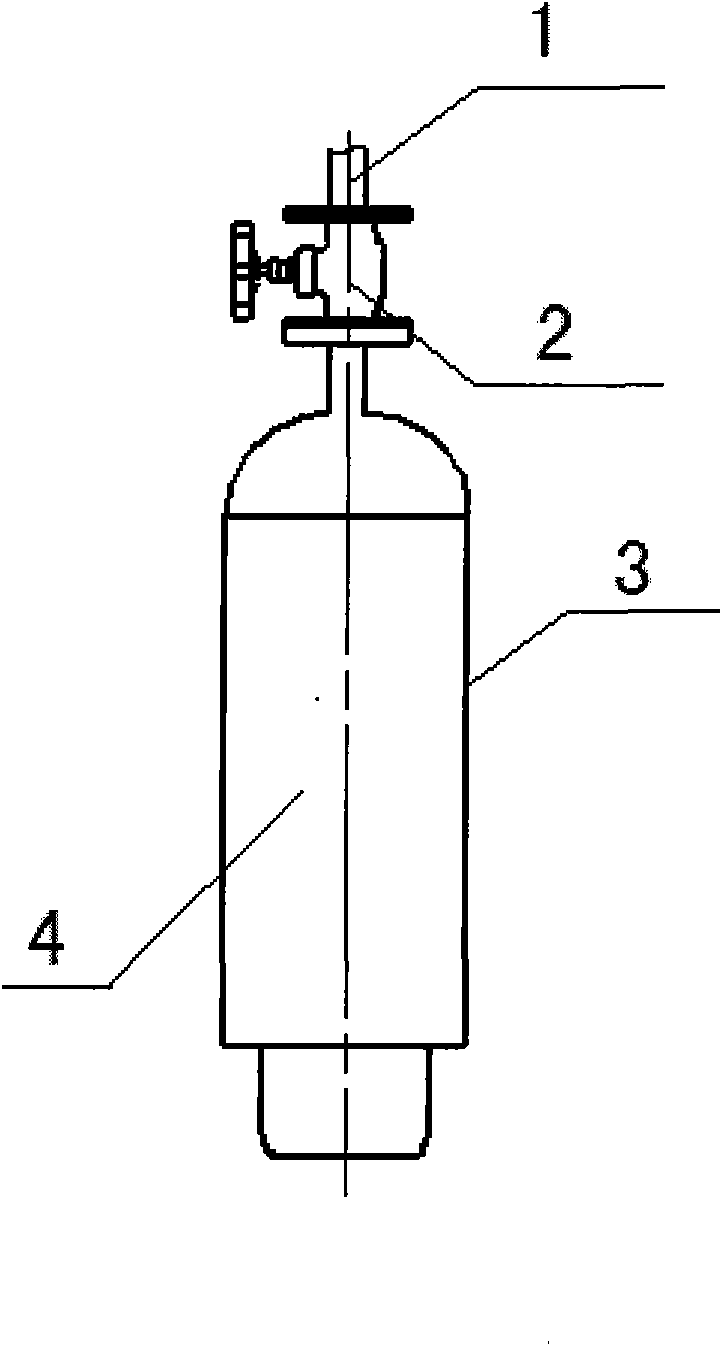

Embodiment 1

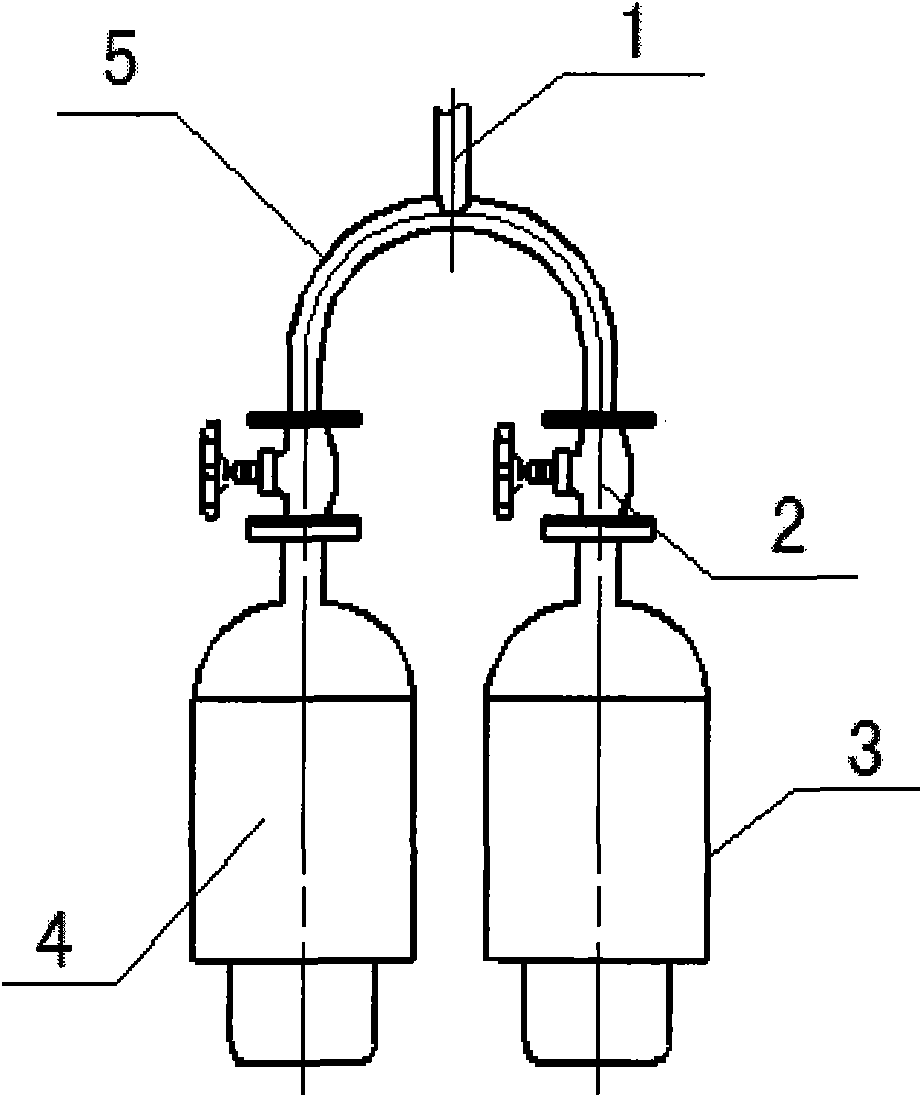

[0017] Such as figure 2 As shown, the new structure is changed from the original oil conservator connecting pipe 1 connected with the moisture absorber to only one tank body 3, to connecting two side-by-side tank bodies through an inverted U-shaped tee pipe 5, the inverted U-shaped The bending radius of the three-way pipe 5 is relatively large, and there is no dead angle. When replacing the silica gel 4 in one of the tanks, it can ensure the unimpeded flow of the oil conservator capsule and the breathing channel of the other tank. Thereby, the original single-can bulky large moisture absorber is optimized into a two-can lightweight moisture absorber. Its length is 3 / 4 of the original length; the weight is 1 / 2 less.

Embodiment 2

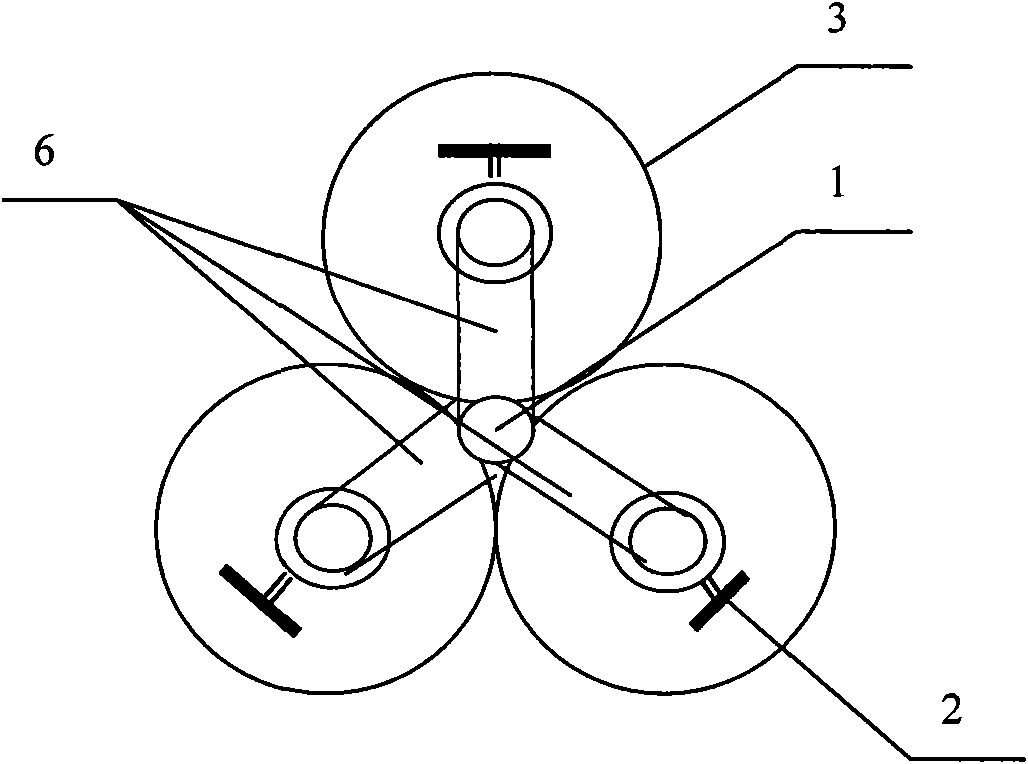

[0019] Such as image 3 As shown, the tank bodies 3 are three arranged in a character shape, and a Y-shaped four-way pipe 6 communicating with the connecting pipe 1 is connected to the vacuum valves 2 of the three tank bodies. When one of the tanks is replaced with the silica gel 4, it can ensure the unimpeded flow of the oil conservator capsule and the breathing passages of the other two tanks.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com