Hub bearing unit

A wheel hub bearing and bearing ball technology, which is applied in the direction of bearing components, hubs, shafts and bearings, can solve the problems of increased weight, increased hub size, and easy vibration of vehicles, and achieves convenient replacement, reduced size, and reduced weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

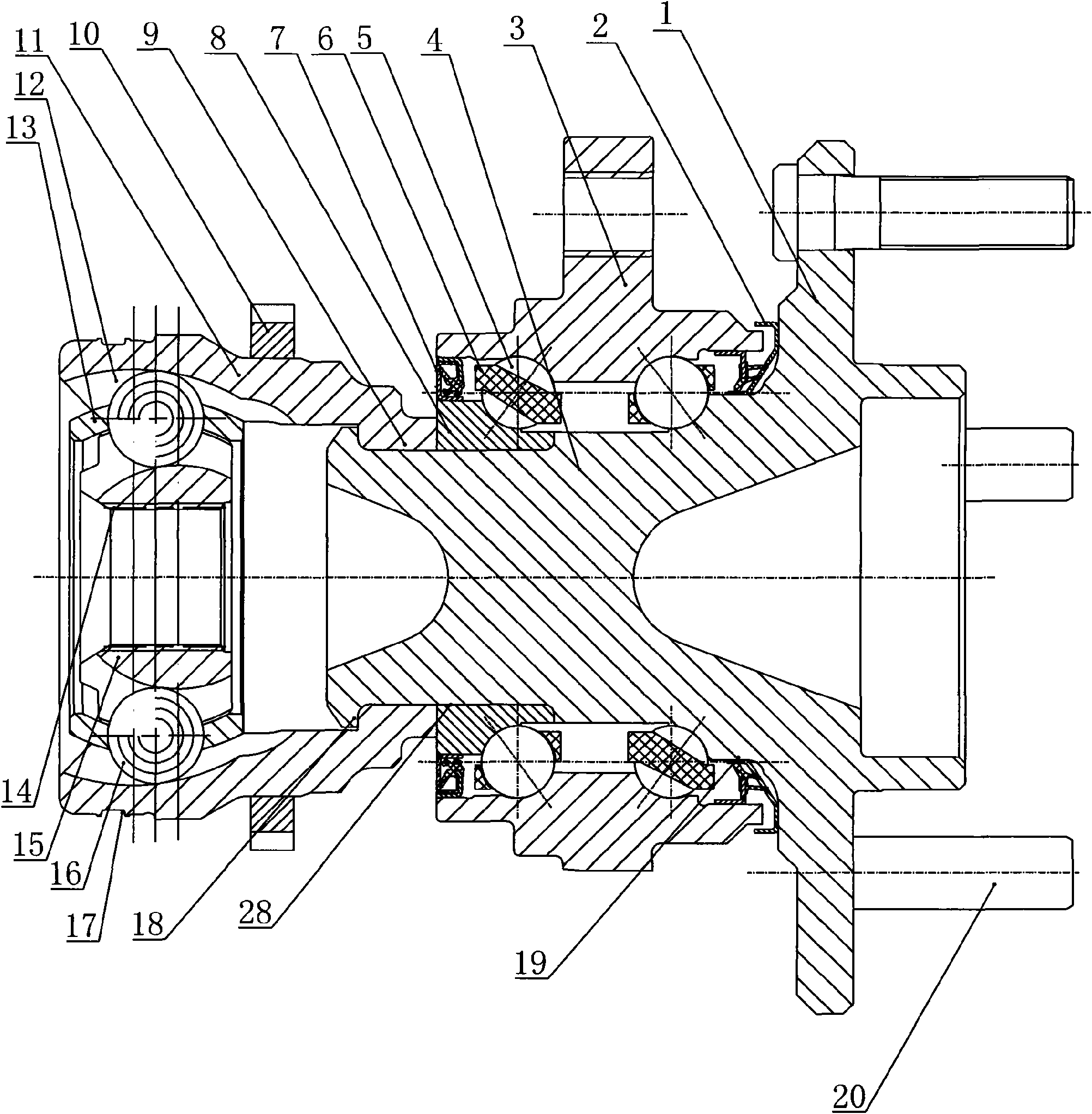

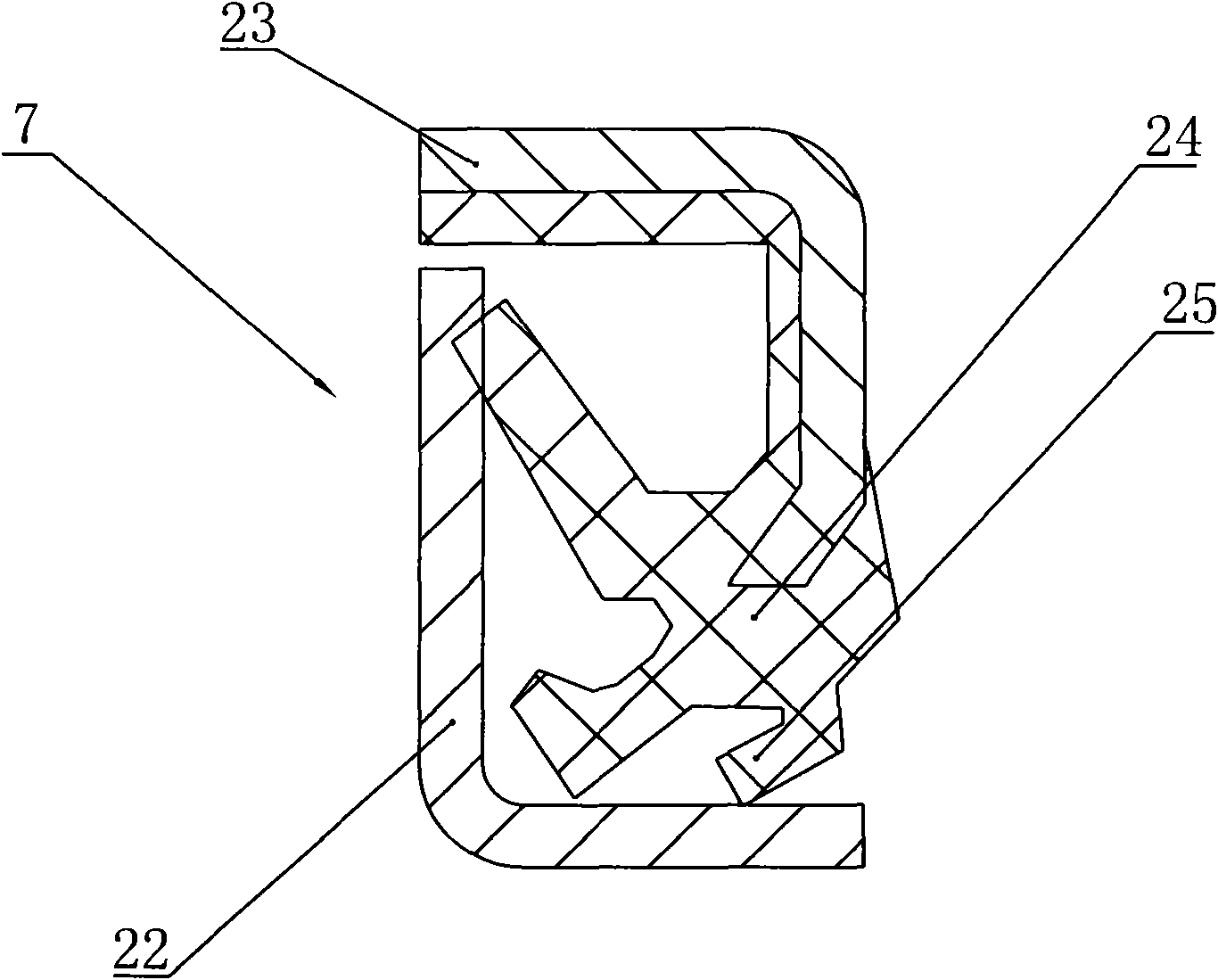

[0022] Embodiment 1: a kind of fourth generation wheel hub bearing unit (see attached figure 1 ), including a flange and an outer ring 3, the flange can be fixed by bolts 20, between the flange and the outer ring are spherical bearing balls 5 arranged in double rows, and the flange includes a flange end face 1 And the long end journal 4, the bearing balls are divided into outer ring bearing balls and inner ring bearing balls, the root of the long end journal is provided with raceways, the outer surface of the inner ring is also provided with raceways, and the corresponding parts of the outer ring are provided with corresponding The middle position of the inner surface of the outer ring is the limit part, and the two rows of bearing balls are placed in the raceway, and the bearing rollers of the same row are fixed by the cage 6, and the root of the long-end journal is provided with a sealing diameter 19, and the sealing diameter There is a sealing ring assembly II2 between the ...

Embodiment 2

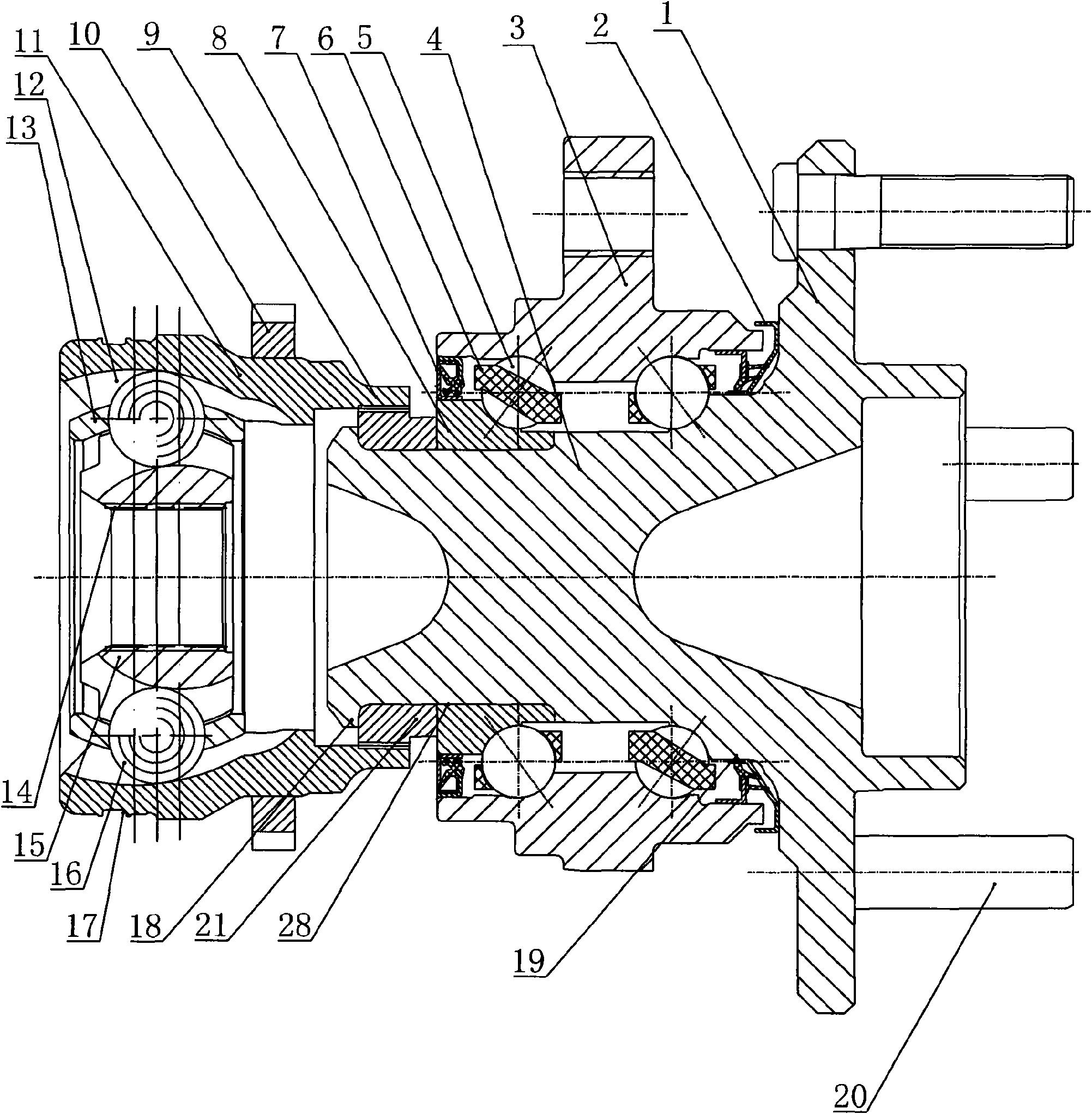

[0024] Embodiment 2: a kind of fourth generation wheel hub bearing unit (see attached figure 2), the difference structure with Embodiment 1 is that the small diameter end of the trumpet-shaped bell-shaped shell is provided with an internal spline, and an external spline ring 21 is nested at the end step of the journal end of the long end, and the external spline ring and the step are formed. Ying connects and supports the inner ring, rolls and wraps and fixes the outer spline ring, the outer diameter of the outer spline ring is larger than the outer diameter of the crimping, and the inner spline at the small diameter end of the bell shell is matched with the outer spline ring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com