Electromechanically integrated industrial sewing machine

An industrial sewing machine, an integrated technology, applied in sewing machine components, sewing machine control devices, sewing equipment and other directions, can solve the problems that limit the technological development of industrial sewing machine application fields, the degree of integration and integration of industrial sewing machines is not ideal, and the use effect of industrial sewing machines is unstable. and other problems, to achieve obvious novelty and creativity, wide practicability, and good production effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and embodiment the present invention will be further described.

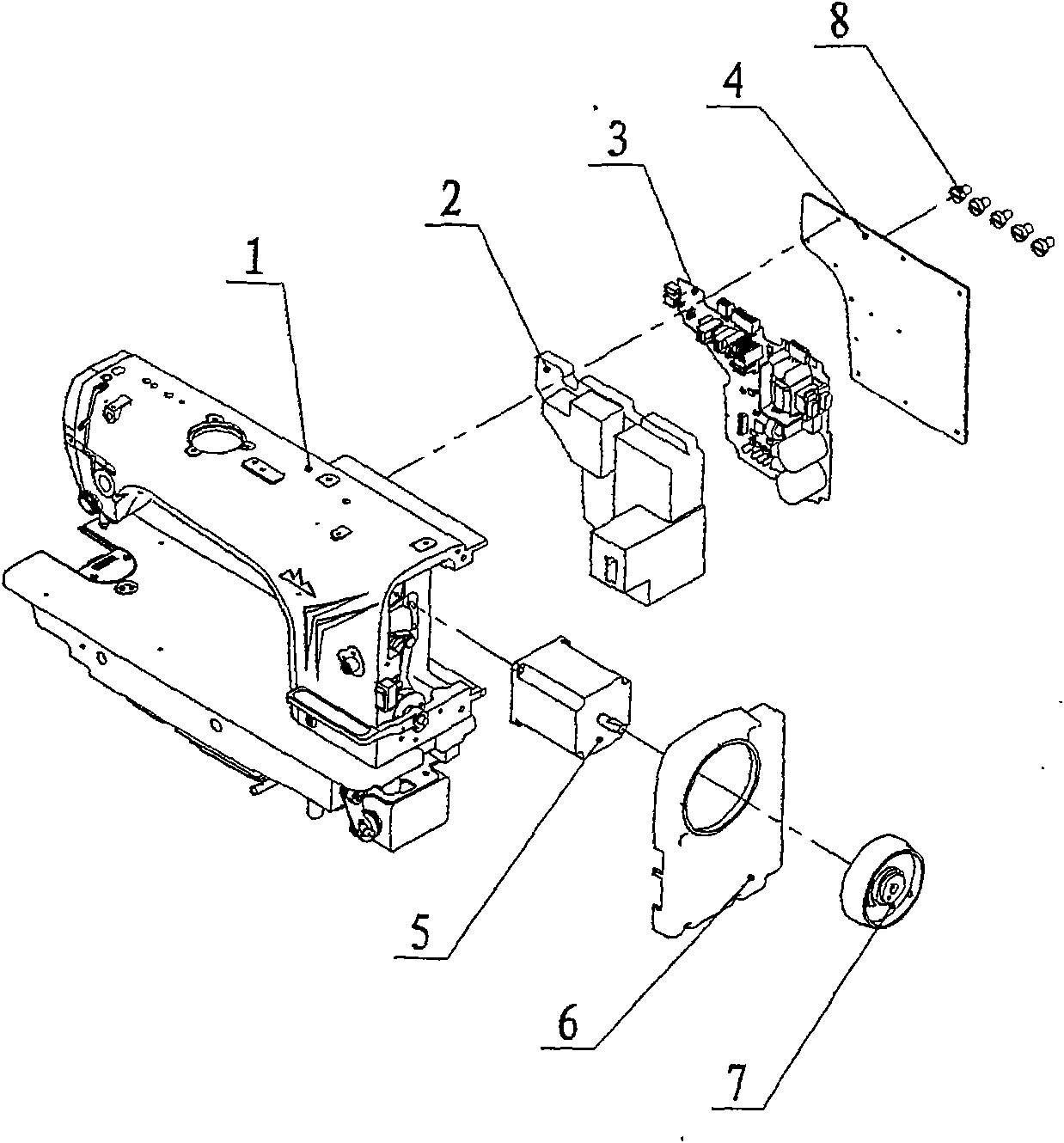

[0021] The electromechanical integrated industrial sewing machine of the present invention, such as figure 1 Shown: Servomotor (5) is installed on the main shaft of industrial sewing machine head (1). A controller box (2) is installed on the rear window of the machine head (1); the controller box (2) is made of metal plate or plastics. The controller (3) is installed in the controller box (2), so that the controller (3) is isolated from the sewing machine head (1), and at the same time, the safety of the controller (3) is protected. The aluminum alloy rear cover (4) is attached to the flat side of the power module of the controller (3) and fixed with screws (8); inserted into the controller box (2), and directly installed into the industrial sewing machine head (1) The rear portion (rear window) of the housing is fixed behind the casing with screws (8). A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com