Breaking type split connecting rod used for compressor and manufacturing method thereof

A technology for a compressor and a connecting rod, which is applied to the fractured split connecting rod for a compressor and its manufacturing field, can solve the problems of high manufacturing precision, high manufacturing cost, great difficulty, etc., and achieves improved stability and easy disassembly and connection. , to avoid the effect of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

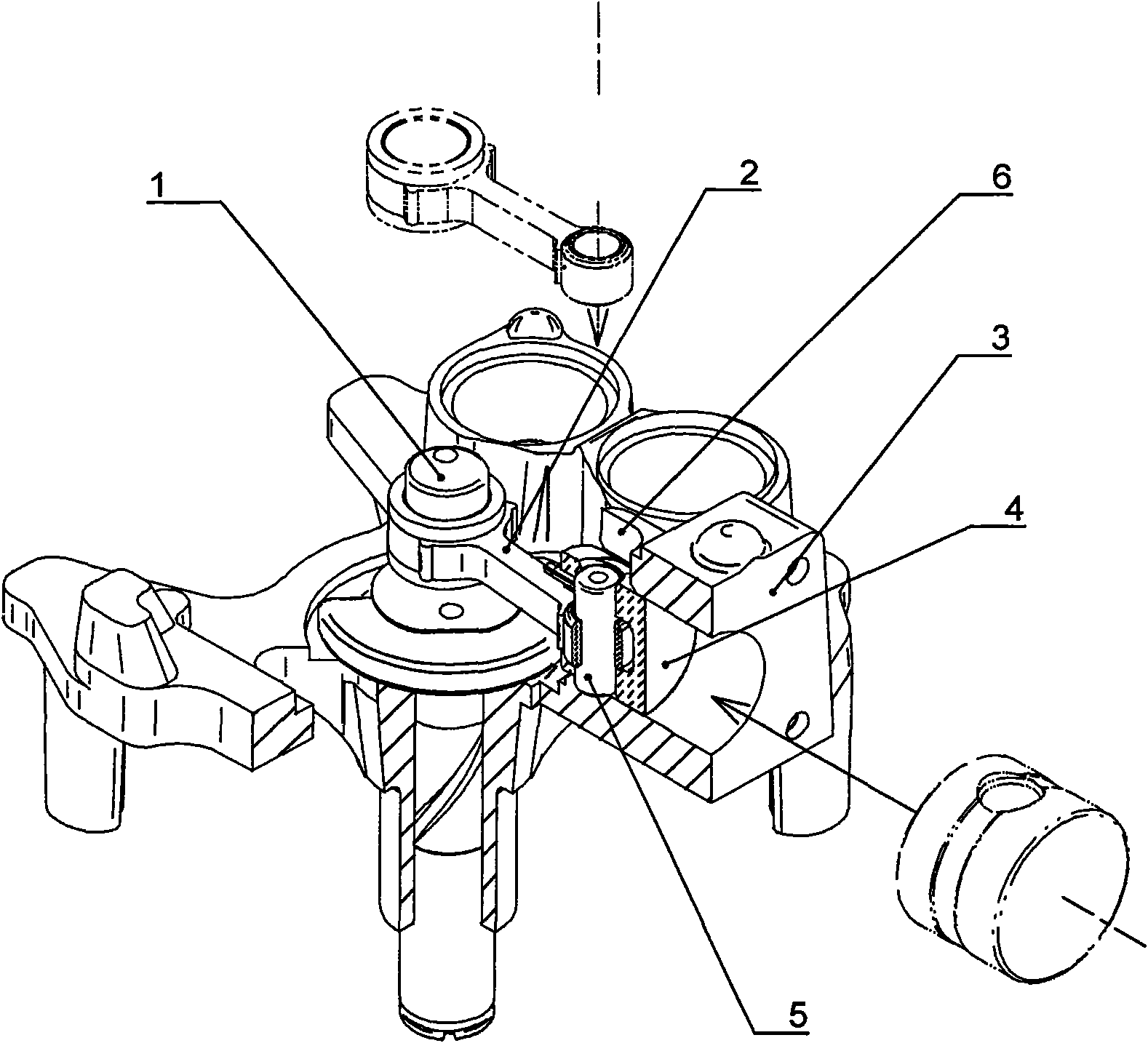

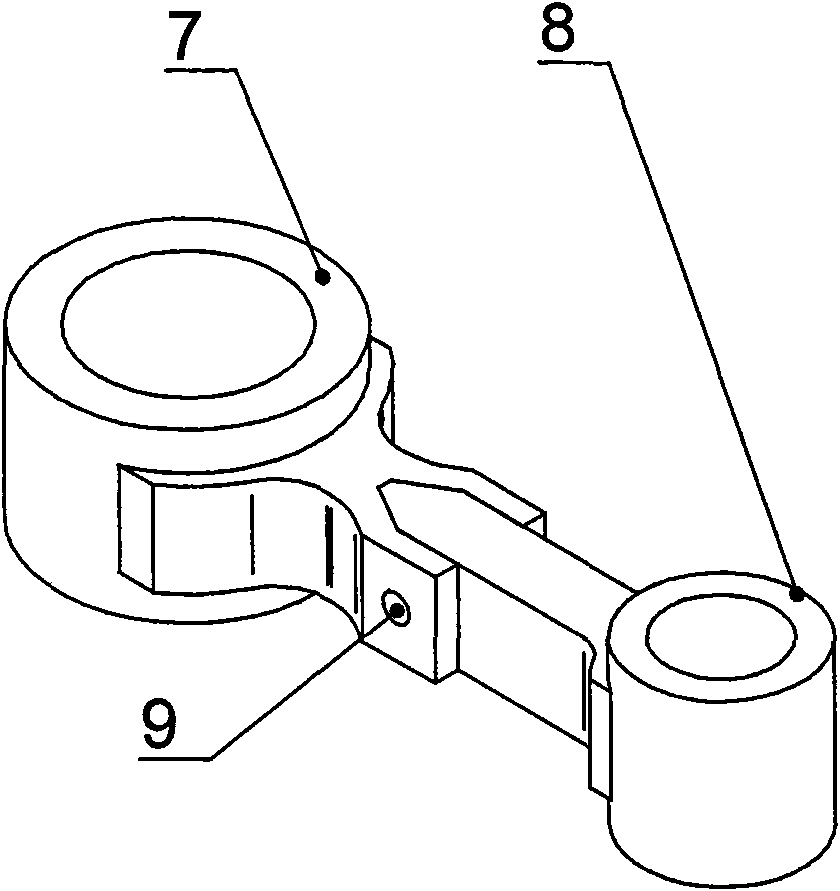

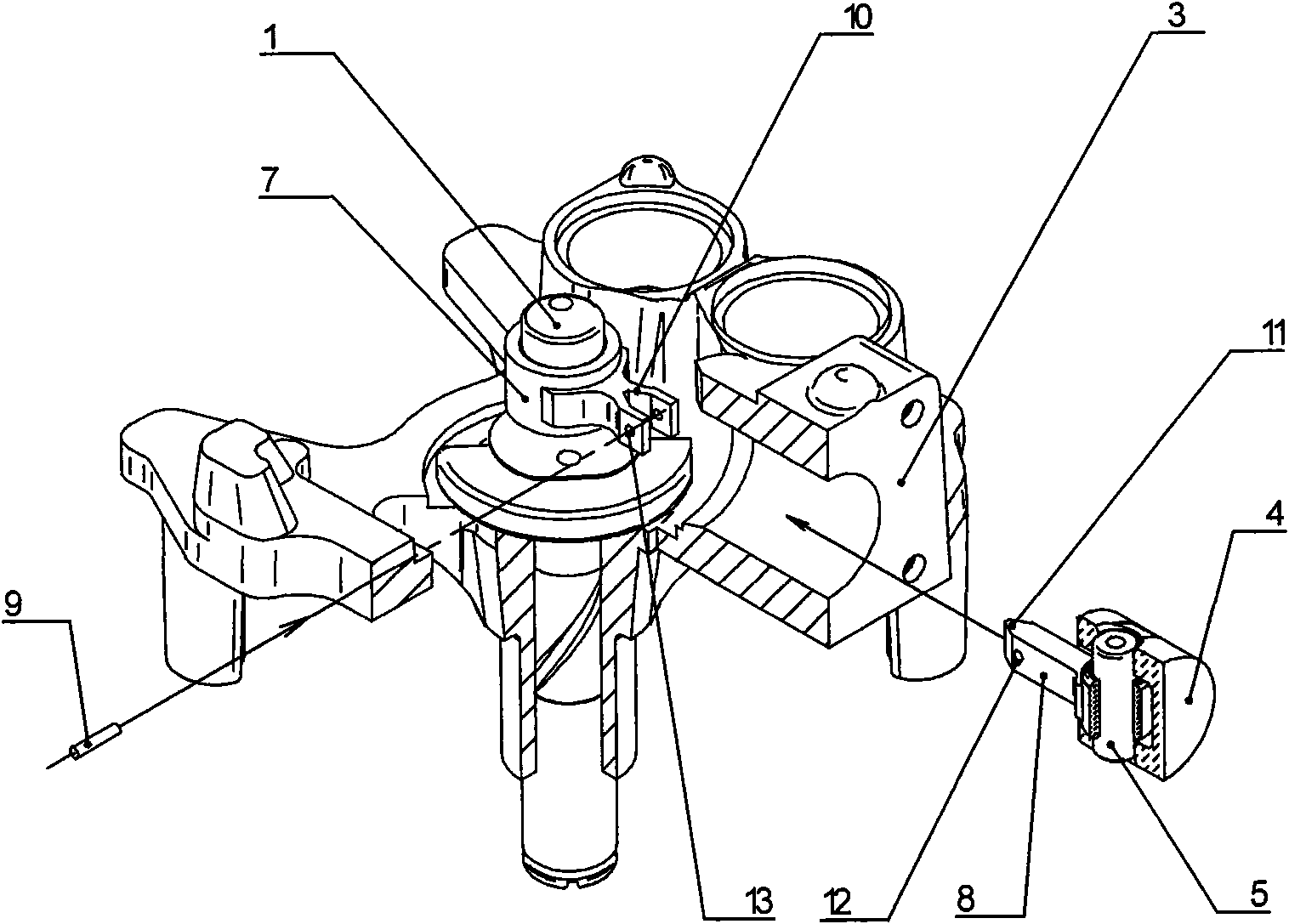

[0018] Such as Figure 4 As shown, the fractured split connecting rod for compressors of the present invention adopts an integral structure before fracture, including the large connecting rod 7 and the small connecting rod 8, which can be formed on a pair of molds, and the manufacturing cost is relatively low.

[0019] Such as Figure 5 As shown, the fractured split connecting rod for the compressor of the present invention is provided with a positioning installation groove 16, a positioning installation groove 17, a fracture groove 20 and a hole 21 before the fracture, and the positioning installation groove 17 is provided with an arc groove 18 and an arc Groove 19. Under the action of external forces F1 and F2, the integral connecting rod is broken at the fracture groove 20 and separated into a large connecting rod 7 and a small connecting rod 8 . Such as Figure 6 As shown, the broken connecting rod big head 7 forms a V-shaped positioning groove 23 at the breaking groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com