Three-joint three-phase asynchronous flame proof vibrating motor

A three-phase asynchronous, vibrating motor technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems that are difficult to improve, and achieve the effect of light weight, reduced weight and good lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

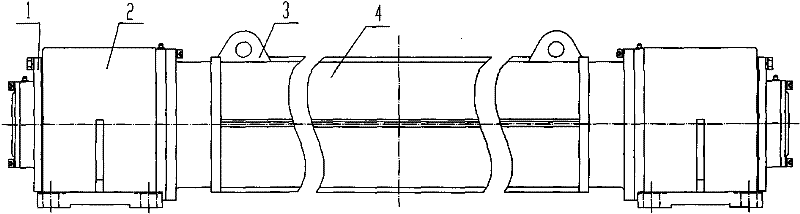

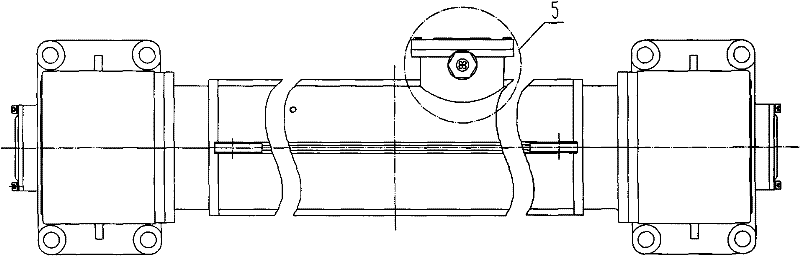

[0020] The present invention is a three-joint three-phase asynchronous explosion-proof vibration motor (abbreviated as the motor) with a slender structure that integrates a power source and a vibration source. The power source is a three-phase asynchronous flame-proof motor, and the vibration source is an eccentric block. It constitutes the excitation source of the vibration equipment.

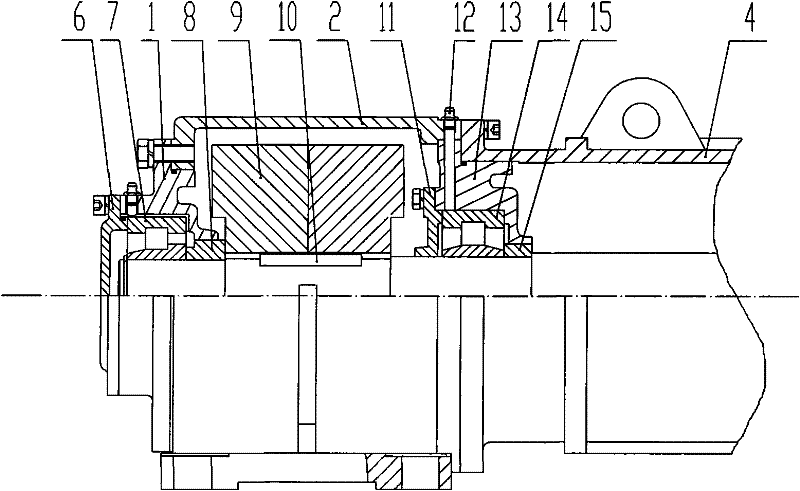

[0021] The structure of the motor is as Figure 1 to Figure 5 Shown: It consists of a three-phase asynchronous flameproof motor and two vibrators 2. Among them: the three-phase asynchronous flameproof motor is composed of a frame 4, a rotor 19 and a stator 18 located in the middle of the frame; an inner seat cover 17 and a third bearing 21 for supporting are arranged between the stator 18 and the bearing seat 13 . Inside each vibrator 2 there are two eccentric blocks 9 connected with the rotor shaft by a key 10; the rotor shaft is the rotating shaft of the rotor 19. The left and right sides...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com