ITO sintered body and ITO sputtering target

A sintered body and secondary sintering technology, which is applied in the field of ITO sputtering targets, can solve problems such as no research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

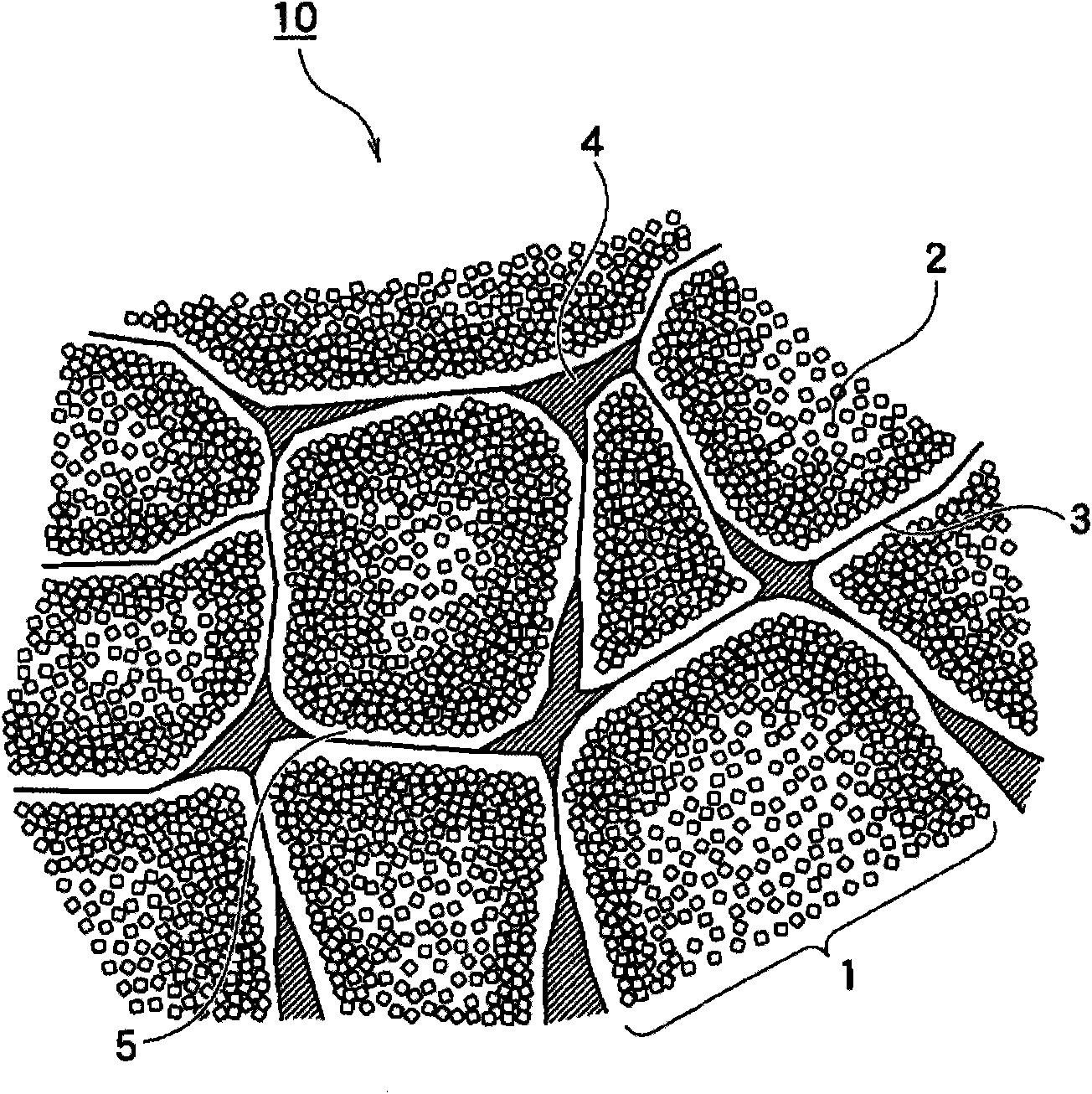

Image

Examples

Embodiment 1

[0088] Indium oxide (In 2 o 3 ) powder and tin oxide (SnO 2 ) powder in a ratio of 90:10 (weight ratio), polyvinyl alcohol (PVA) as a binder was added to the powder, and ball milling was carried out. at 800kg / cm 2 The resulting mixed powder was compression-molded under an extrusion pressure of 100,000°C, and degreased in air to obtain a molded body.

[0089] The resulting molded body is placed in the state of the sintered plate and then put into a batch heating furnace, and the oxygen concentration of 100% is blown into the furnace while oxygen (for every 1m 3 The volume of the furnace, the amount is 1m 3 / h), the furnace is heated to 1600°C, and the holding time at this temperature is set to 0 seconds (instant), and then the temperature is immediately lowered to 1550°C. Then, after holding at 1550° C. for 2 hours, the oxygen in the furnace was replaced with argon and held for another 6 hours. At this time, the oxygen concentration in the furnace was 10.1%. Thereafter, ...

reference example 1

[0116] Manufacture the ITO molded body identical with embodiment 1, the molded body of gained is placed in the state of burning plate and then puts into the batch heating furnace again, blowing into the oxygen concentration in the furnace is the oxygen of 100% while (for each 1m 3 The volume of the furnace, the amount is 1m 3 / h), heat the furnace to 1600°C, and keep it at this temperature for 8 hours, replace the oxygen in the furnace with air, and blow in the air at the same time (for every 1m 3 The volume of the furnace, the amount is 1m 3 / h) cooling to room temperature, thereby obtaining an ITO sintered body.

[0117] The average temperature rise rate in the heating step at this time was 117° C. / hour, and the average temperature drop rate in the cooling step in the temperature range from 1600° C. to 400° C. was 175° C. / hour.

[0118] The firing conditions are shown below.

[0119] "Firing Conditions"

[0120] Room temperature→(50℃ / hour)→400℃→(100℃ / hour)→800℃×4 hours→...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume resistivity | aaaaa | aaaaa |

| Volume resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com