Sputtering target material and sputtering target obtained by using the sputtering target material

A sputtering target and sputtering target technology, applied in the field of sputtering targets, can solve the problems of reducing arcs, unable to fully suppress target cracks and cracks, etc., so as to reduce the generation of arcs and inhibit the generation of cracks or cracks. , the effect of improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

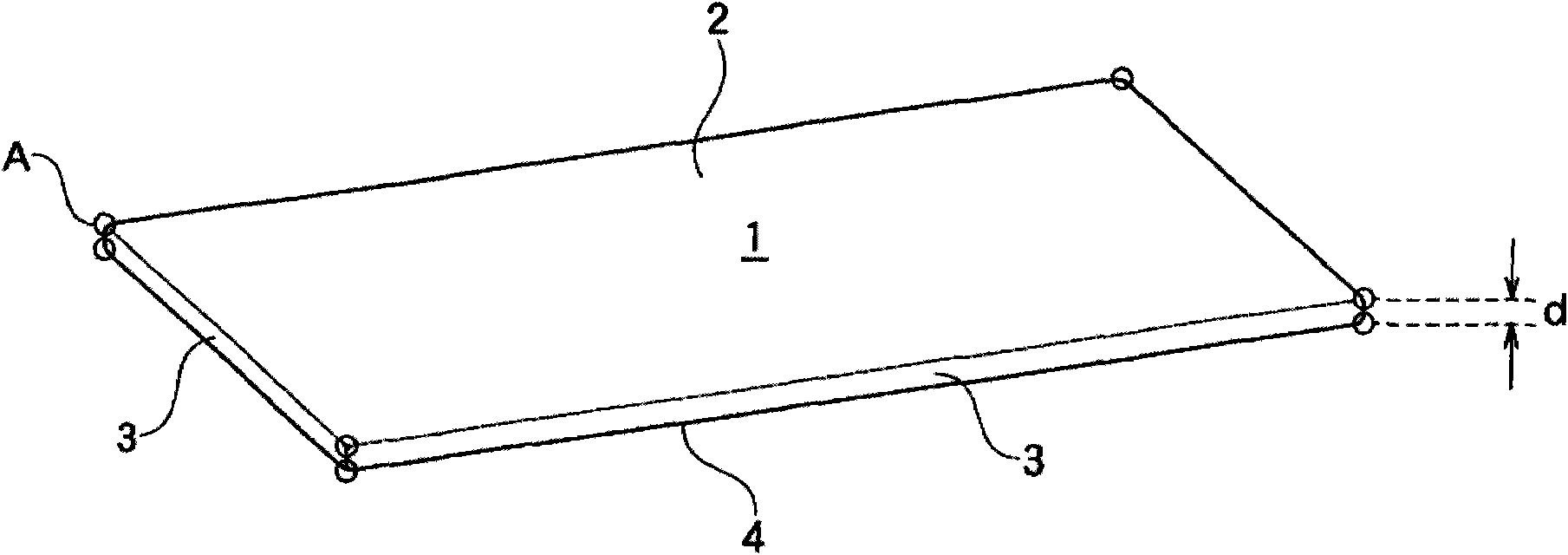

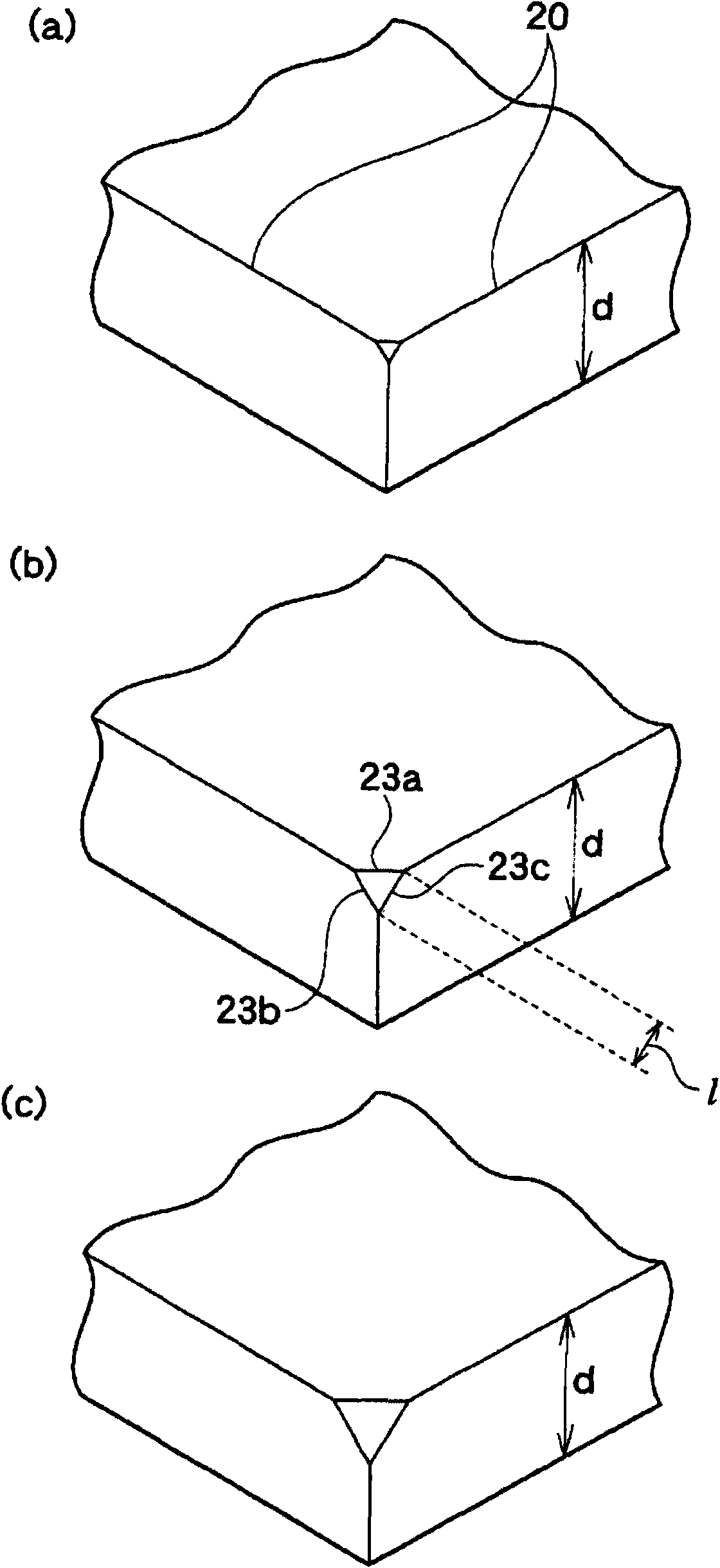

[0114] Such as Figure 6 As shown, a nearly plate-shaped ITO sputtering target (SnO 2 =10% by weight, the relative density is 99.8%), the chamfering treatment of R1 was performed on the edge parts 45a-45c, and the chamfering treatment of R1 was performed on the four corners A located on the sputtering surface 2.

[0115] Then, this sputtering target 1 was bonded to a back plate (230×750×20 mm) made of oxygen-free copper using the above-mentioned adhesive material, thereby producing a sputtering target. Using the obtained sputtering target, evaluation was performed on each of the evaluation items described above. The obtained results are shown in Table 1.

Embodiment 2

[0120] The ITO sputtering target composed of the materials shown in Table 1 was manufactured, and the chamfering treatment of C0.3 was implemented on the four corners A of the sputtering surface 2, and the edges and corners of the bonding surface were C0.5 chamfering treatment is implemented on the part.

[0121] Then, in the same manner as in Example 1, a sputtering target was produced, and various evaluations were performed. The obtained results are shown in Table 1.

Embodiment 3~9、 comparative example 3~5

[0126] ITO sputtering targets composed of the materials shown in Table 1 were manufactured, and chamfering was performed on the edges or corners according to the contents shown in Table 1.

[0127] Then, in the same manner as in Example 1, a sputtering target was produced, and various evaluations were performed. The obtained results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com