SiSb based phase-change thin-film material used for phase-change memory device

A phase-change memory and thin-film material technology, which is applied in the field of materials in the field of microelectronics technology, can solve problems affecting the contact between phase-change thin films and electrodes or other film layers, affecting device stability, and unfavorable device operation, etc., to achieve superior amorphous State stability, fast crystallization rate, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

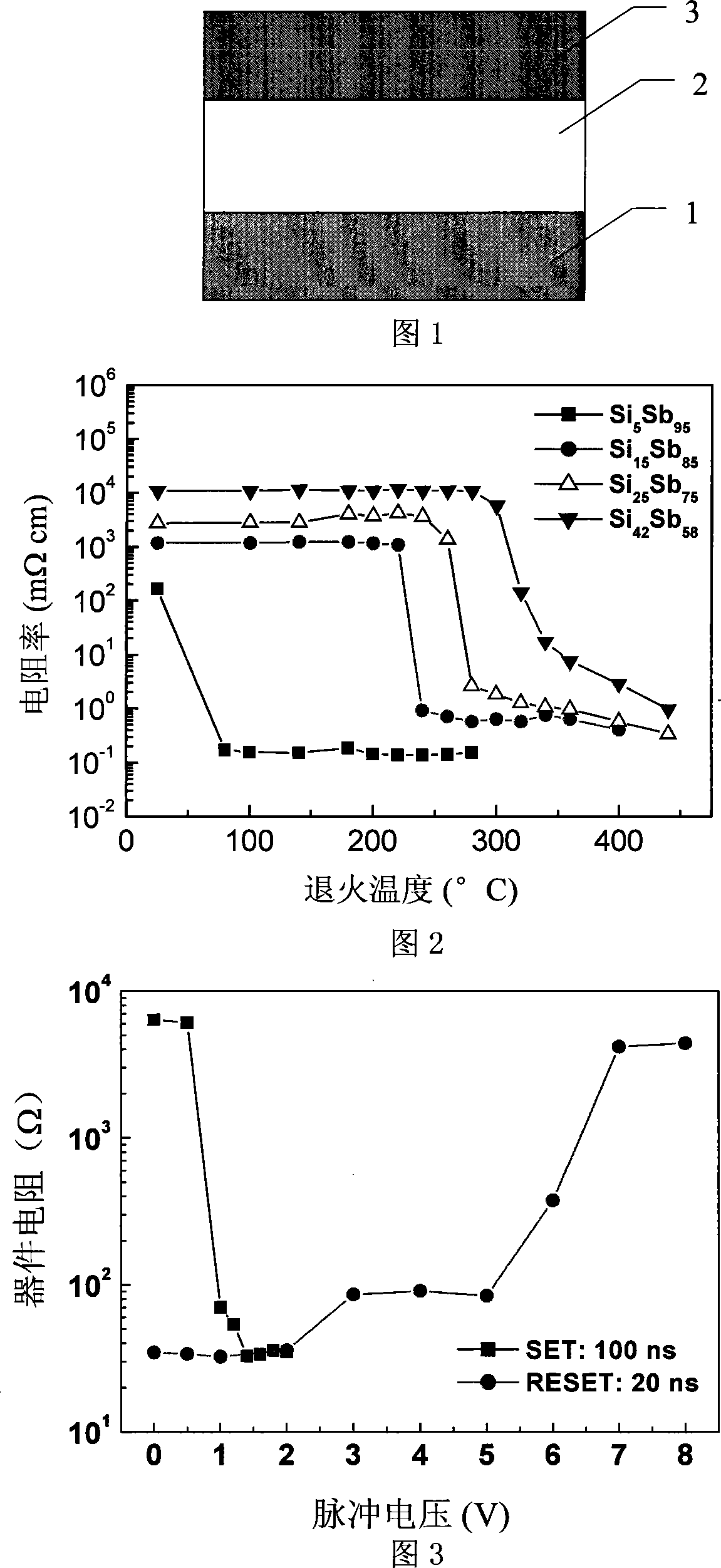

[0022] The phase change material series is a SiSb-based phase change film, that is, when the doping element content y is 0, the specific composition is Si x Sb 1-x , wherein the Si content x is 5-90% atomic percent. A particularly suitable composition is that the Si content can be 10-60 atomic percent.

[0023] Figure 2 shows Si with different Si content x Sb 1-xThe relationship between film resistivity and annealing temperature. When the film is in an amorphous state, the film resistance is in a high resistance state, and as the annealing temperature increases, the film begins to crystallize, and when the film crystallizes, the film resistance is in a low resistance state. This process is realized in the memory device by heating the phase-change film with electric pulses, and the reversible transition between the high-resistance state and the low-resistance state can be achieved by applying different electric pulses. When Si content x is 5%, Si 5 Sb 95 The crystallizat...

Embodiment 2

[0035] The phase change material series is doped Si x Sb 1-x Alloy film: (Si x Sb 1-x ) 1-y m y , wherein the doping element M can be 0 element or N element or their mixture, the content y of the doping element M is 0-15 atomic percent, and the Si content x is maintained at 5-90 atomic percent.

[0036] In a specific embodiment, an oxygen-doped SiSb-based phase change film is prepared by reactive sputtering. Oxygen doping can also be implemented by implanting oxygen ions into the SiSb phase change film. Oxygen-doped Si x Sb 1-x The relationship between resistivity and annealing temperature of the phase change film is similar to that in Figure 2, that is, as the annealing temperature increases, the film crystallizes and changes from a high-resistance state to a low-resistance state. Oxygen-doped Si x Sb 1-x Phase change films can also be used in phase change storage media. Oxygen doping makes Si x Sb 1-x The amorphous resistivity of phase change films can be increa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com