Stainless steel zipper manufactured by metal injection molding and preparation method thereof

A technology of injection molding and manufacturing method, applied in application, apparel, sliding fastener components, etc., can solve the problems of insufficient product development and innovation ability, lack of international competitiveness, declining product profit margin, etc., to achieve fine surface, not easy to oxidize, The effect of improving product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

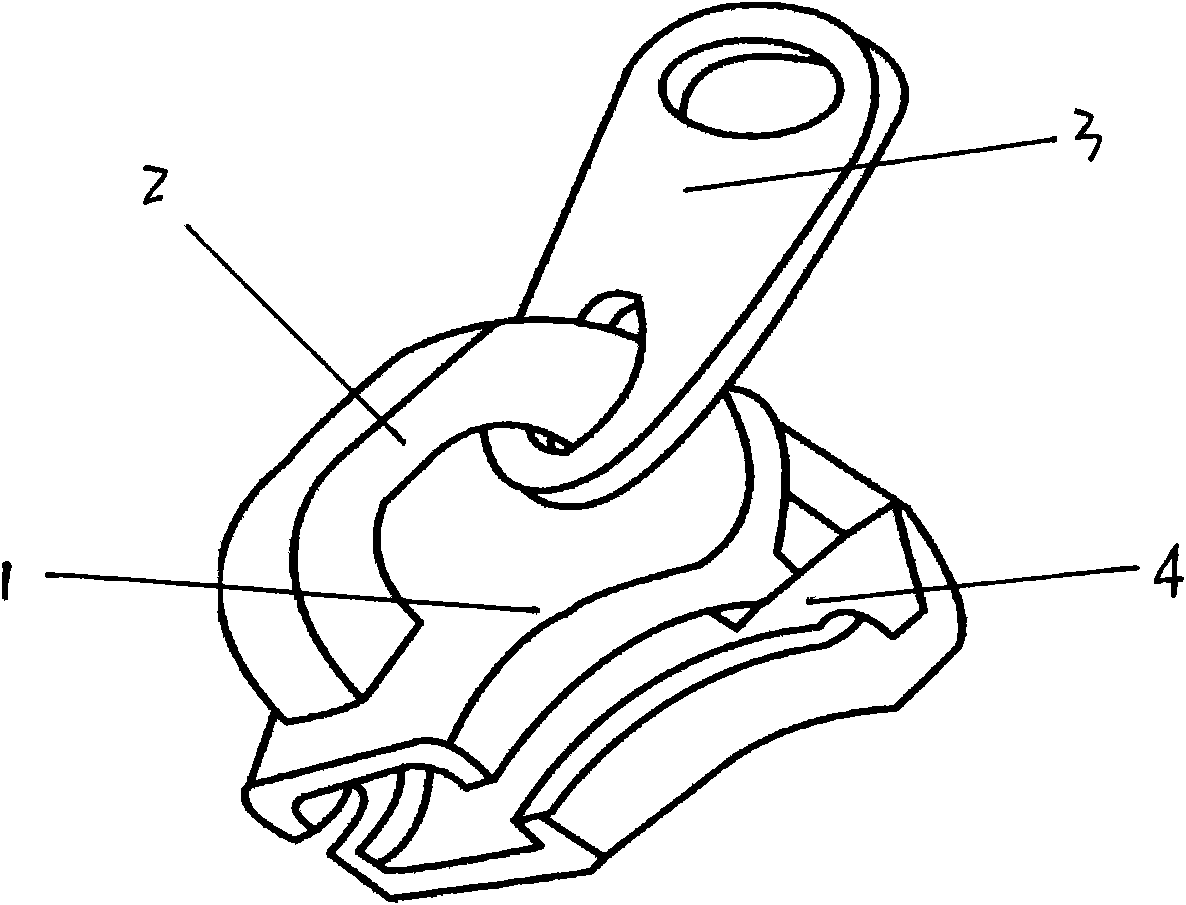

Image

Examples

Embodiment 1

[0030] ① Design the molds for the main parts of stainless steel zipper;

[0031] ② Choose metal powder for metal injection molding stainless steel zipper;

[0032] ③. Choose to equip with metal injection molding stainless steel zipper binder;

[0033] ④. Mix the metal powder and binder prepared in the process of ② and ③ into a uniform feed according to the specified volume and strength ratio;

[0034] ⑤. Inject the uniform feed prepared in the process of ④ into the mold after being heated and flowed at high temperature, and then cooled and formed;

[0035] ⑥. Use wax-based adhesive to cool and shape;

[0036] ⑦. Sintering the above-mentioned degreased stainless steel zipper to form a finished product.

[0037] The metal powder described in the method of the present invention is selected from 304L stainless steel powder, 317L stainless steel powder, 410L stainless steel powder, 430L stainless steel powder, 434L stainless steel powder, 440A stainless steel powder, 440C stainless ste...

Embodiment 2

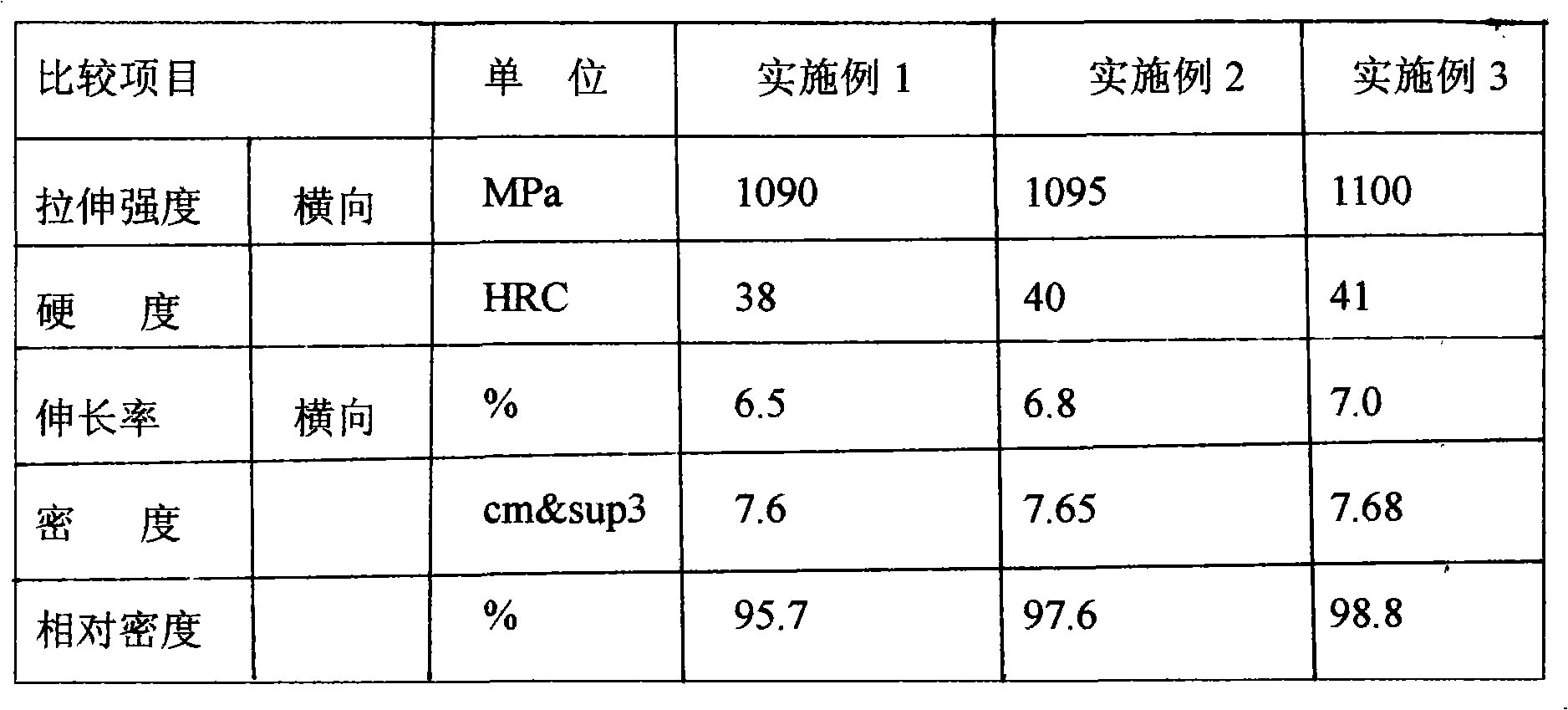

[0043] Select 50% of the stainless steel metal powder in step ④, and 50% of the binder by volume and force to mix into a uniform feed; the temperature is controlled at 110 degrees, and the viscosity of the mixture is 50pa.s; step ⑥ the plastic-based binder is used for cooling For forming, the temperature is controlled at 110 degrees; step ⑦ the temperature is controlled at 110 degrees; the rest is the same as in Example 1. The performance of the finished stainless steel zipper is shown in the table below.

Embodiment 3

[0045] Select 65% of the stainless steel metal powder in step ④, and select 35% of the binder by volume to mix into a uniform feed; the temperature is controlled at 150 degrees, and the viscosity of the mixture is 220 pa.s; step ⑥ is a wax-based binder Cooling and forming, the temperature is controlled at 150 degrees; step ⑦ the temperature is controlled at 150 degrees; the rest is the same as in Example 1, the performance of the stainless steel zipper finished product obtained is shown in the table below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com