Hot die-pressing production technique of shackle and die thereof

A production process, hot molding technology, applied in the direction of manufacturing tools, metal processing equipment, forging/pressing/hammer devices, etc., can solve the problems of high noise pollution, no pressing mold, high labor intensity, etc., and achieve product yield and The effect of improving material utilization rate, saving product cost and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] For the production of A-type straight anchor shackles (A-type straight anchor shackles: 3.5≤λ≤5.5; λ is the ratio of the length of the workpiece aggregated into a ball and the diameter of the workpiece, the same below).

[0018] The first step is to prepare materials. According to the specifications of the shackles, select the corresponding round steel billets.

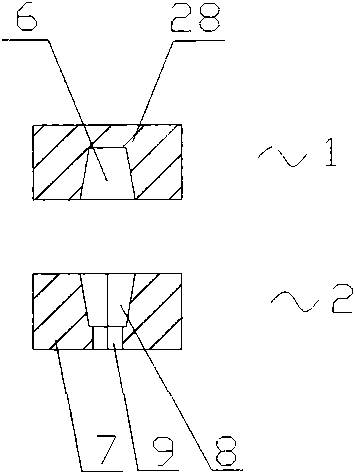

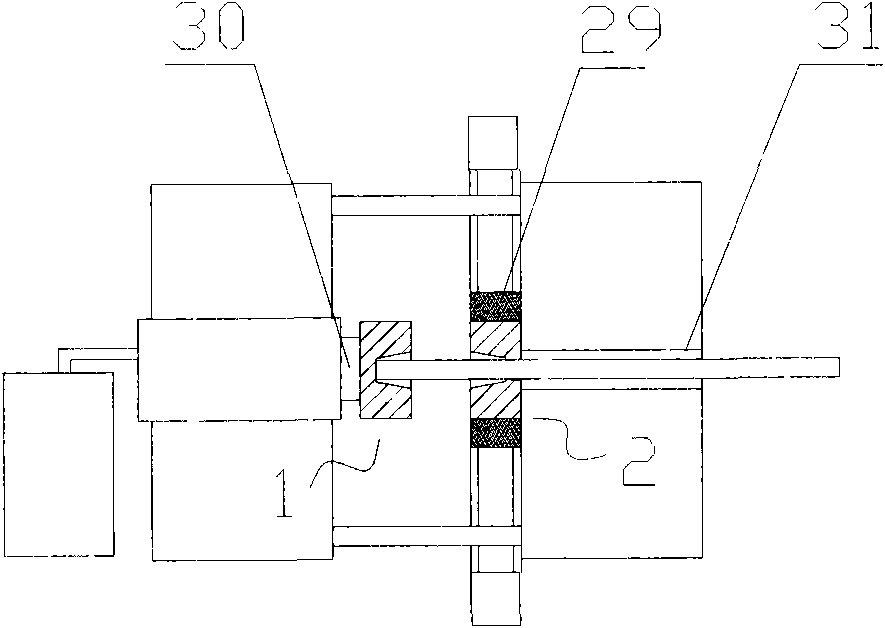

[0019] The second step is to gather materials, heat one end of the round steel billet to keep its temperature at 750-1220°C, and put it into the pressing mold. The mold of this embodiment is as figure 1 , 2 As shown, the mold is composed of an upper mold 1 and a lower mold 2, wherein the upper mold 1 is connected with the pressing rod 30 of the pressing equipment, and the left and right opening and closing lower mold 2 is connected with the clamping mechanisms 29 on both sides; its specific structure is The upper mold 1 is formed by a cone-like cavity 6 in the center of the lower end face of the cylindrical m...

Embodiment 2

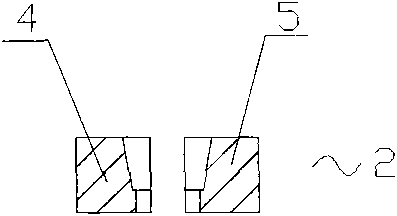

[0025] For the production of Class B straight anchor shackles (3.0≤λ≤4.5), the process is basically the same as in Example 1: the first step is to prepare materials; the second step is to gather materials; the third step is to form balls; the fourth step is The sphere is flattened; the fifth step is to form a hole; the sixth step is to bend. Among them, because λ is relatively small, the aggregate is used as Figure 5 The specific structure and aggregate action of the mold shown are as follows: the upper mold 19 is formed by a cone-like cavity 21 in the center of the lower end surface of the cylindrical metal block 20; the lower mold 22 is composed of left and right opening and closing molds 23 with the same structure , 24 combined, when the lower mold 22 is closed as a whole, the center of the upper end surface of the cylindrical metal block 25 is formed by a hemispherical cavity 26 and a cylindrical hole 27 opened through the metal block at the center of the bottom end of th...

Embodiment 3

[0027] For the production of Type C straight anchor shackles (λ≤3.5), the specific implementation method is the same as that of Example 1. Since its λ is very small, it is only necessary to directly ball the two ends of the round steel billet. The following steps are required for the type anchor shackle: the first step is to prepare the material; the second step is to form a ball; the third step is to flatten the sphere; the fourth step is to form a hole; the fifth step is to bend. Due to the direct ball forming, the selected pressing die is Figure 4 The mold shown, its structure and ball forming action have been stated in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com