Parallel 3-DOF drive mechanism of spindle head

A driving mechanism and degree-of-freedom technology, which is applied to driving devices, metal processing mechanical parts, large fixed members, etc., can solve the problems of complex design of machine tool structural parts, high cost, flexibility and reduced structural rigidity, etc., to achieve simple structure and cost. Effects of low, low motion quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

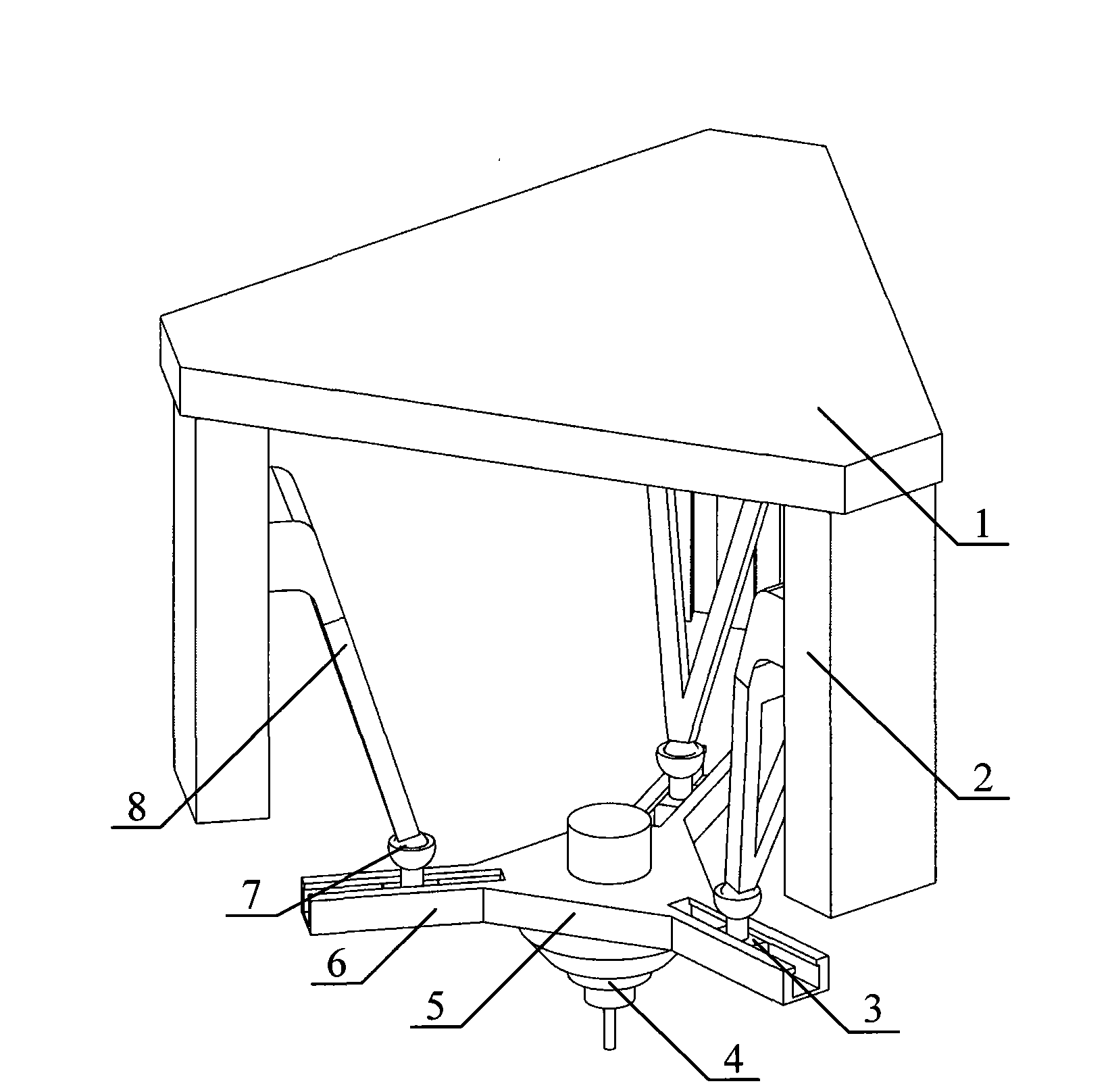

[0010] The present invention provides a parallel three-degree-of-freedom spindle head driving mechanism. The present invention will be further described in conjunction with the accompanying drawings and specific embodiments below.

[0011] figure 1 It is a structural schematic diagram of an embodiment of the present invention. Three driving and moving pairs 2 distributed according to the apex positions of an equilateral triangle are installed on the fixed platform 1; each driving and moving pair 2 is connected with an input rod 8, and the input rod 8 is driven by the driving and moving pair 2; The other end is connected to the ball hinge 7, and is connected to the connecting slider 3 through the ball hinge 7; the equilateral triangle dynamic platform 5 is provided with 3 evenly arranged passive moving pairs 6, the passive moving pair 6 is a chute, and the 3 connecting sliders 3 They are respectively installed in the chute of the passive moving pair 6, and can move horizontall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com