Method and device for continuously and automatically metering irregular cans of canned goods and filling lobster sauces

A technology of automatic measurement and special-shaped cans, which is applied in the field of food processing, can solve the problems of low degree of mechanization of the production line, lack of market competitiveness, and high labor intensity, and achieve the effects of facilitating continuous production, improving labor productivity, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

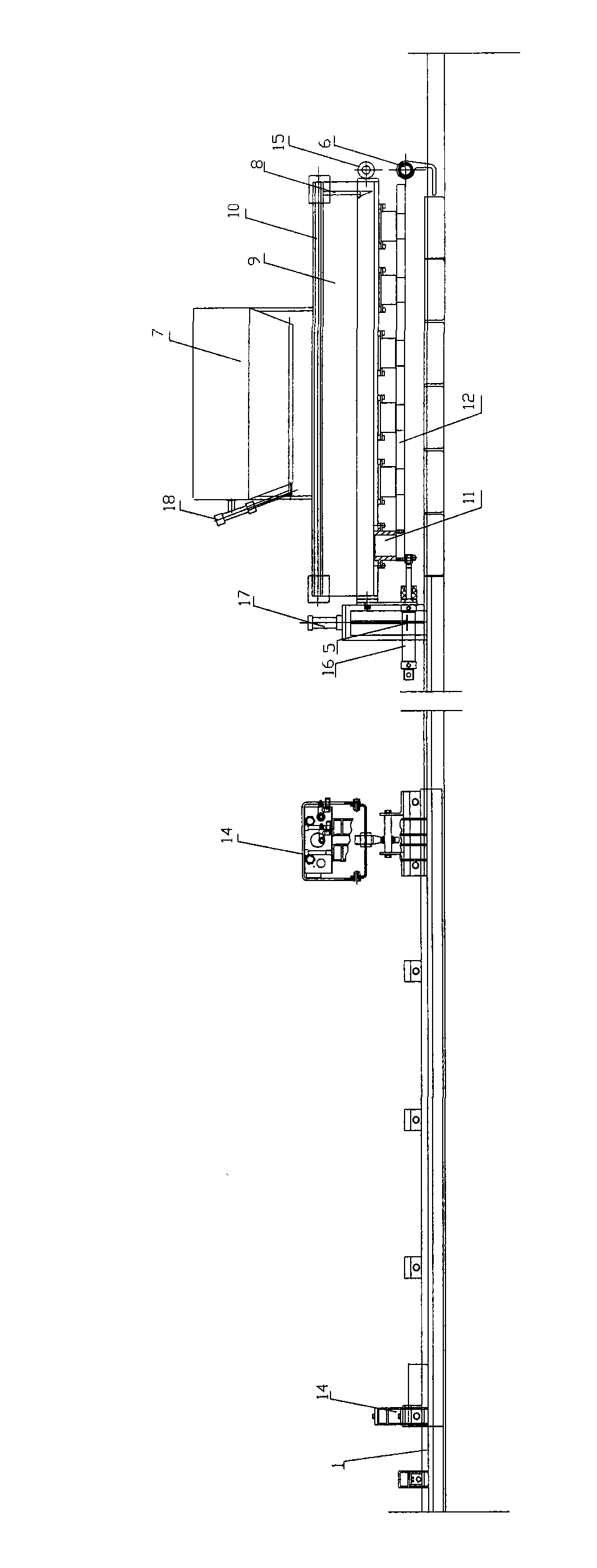

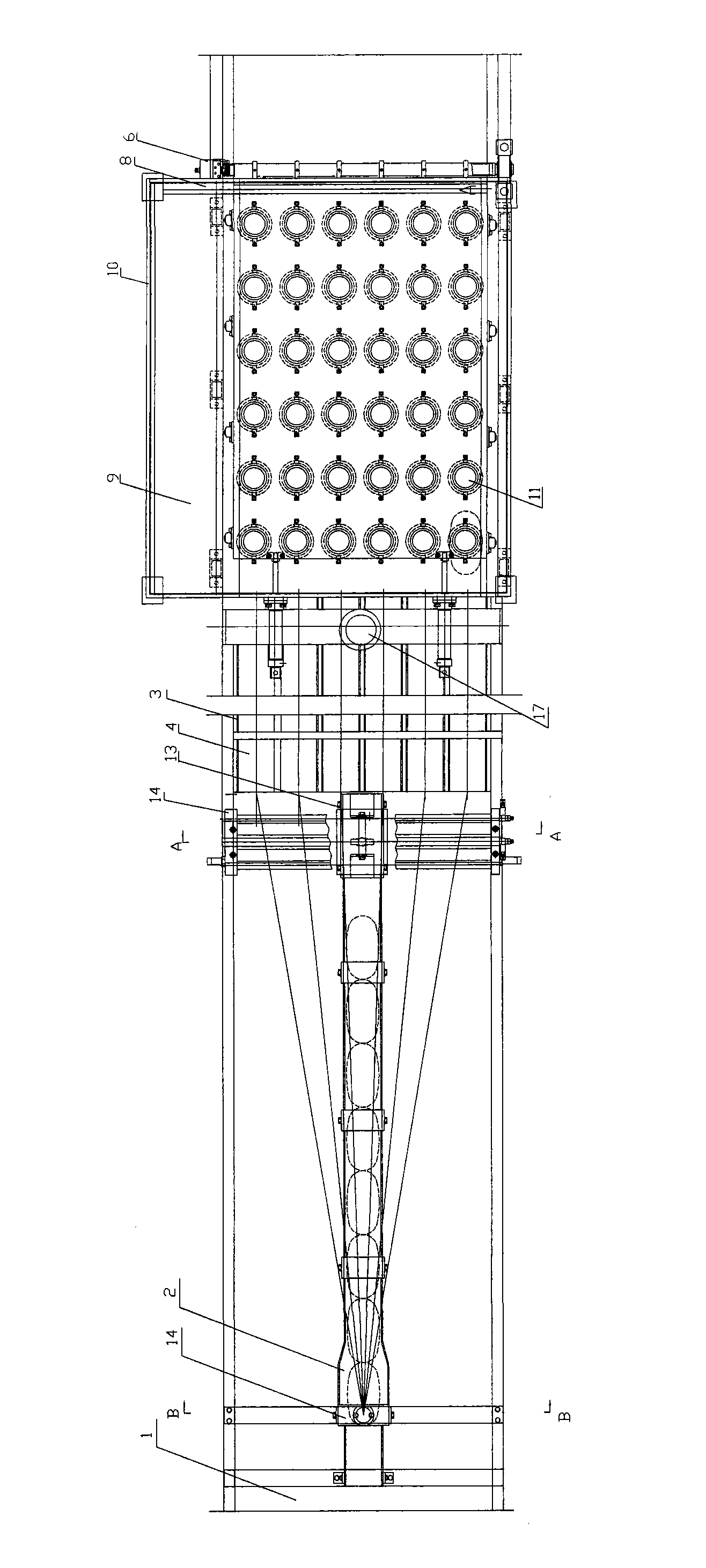

[0040] The present embodiment is a kind of method that is used for the continuous automatic metering of special-shaped cans and adding fermented soya bean, comprises the following steps, as figure 1 The main view of the equipment structure and figure 2 The top view shows:

[0041] (1) Swing-type single-channel conveyor belt 2 arranges special-shaped tanks to each interval channel 4;

[0042] (2) The multi-channel conveyor belt 1 sends the arranged special-shaped tank to the corresponding position below the feeder 9;

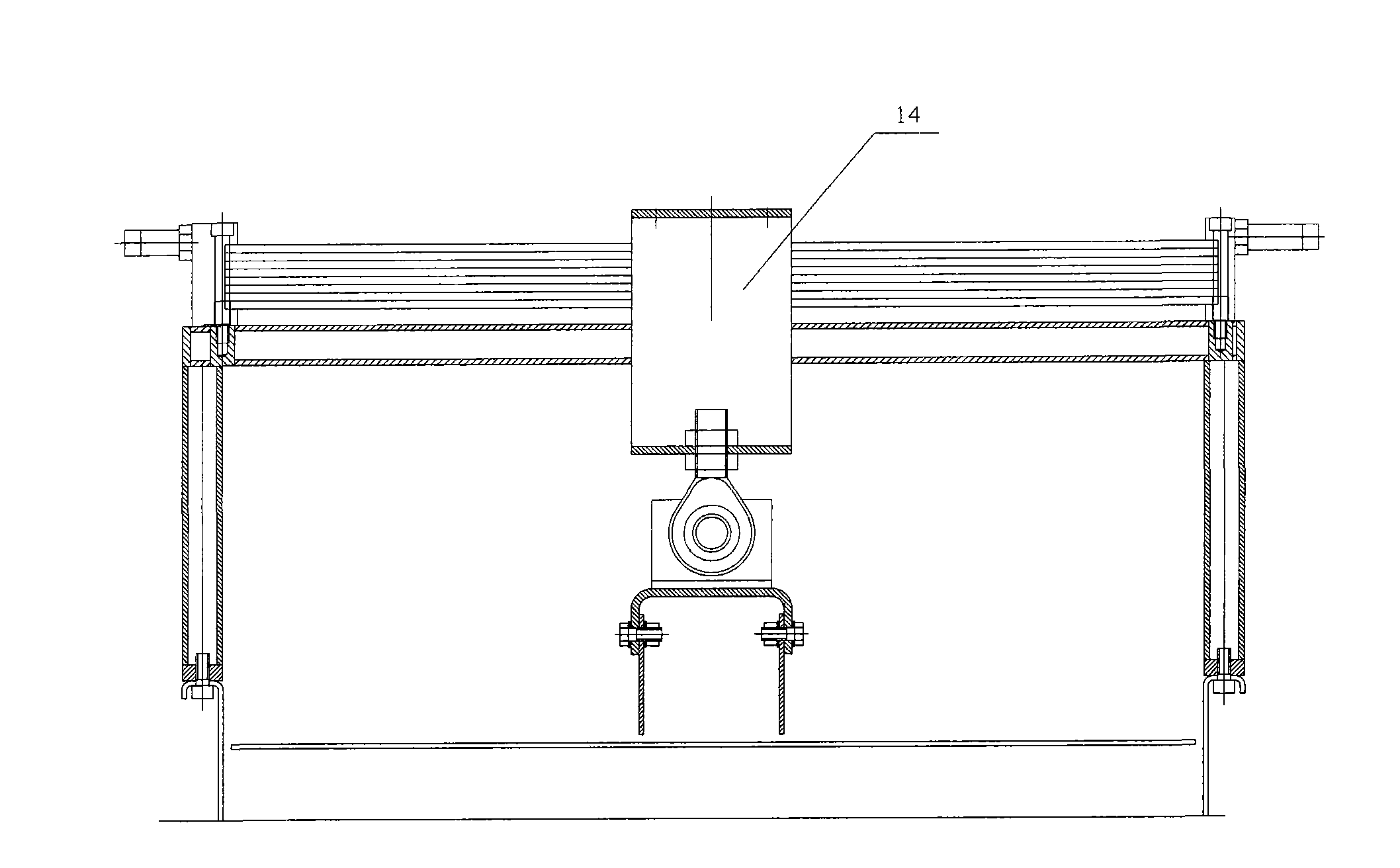

[0043] (3) The can pressing mechanism 5 and the tank retaining cam 6 located at both ends of the feeder 9 press down respectively, and the tank press mechanism 5 presses the special-shaped tank adjacent to the press tank mechanism 5 on the outside of the feeder 9, and the tank retaining cam 6 Block the special-shaped tanks that have entered the bottom of the feeder 9, so that the various special-shaped tanks that enter the bottom of the feeder 9 are fixed at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com