Technique for reagent-free in situ leaching uranium mining from sandstone type uranium deposit

A technology for in-situ leaching mining of uranium and uranium deposits, applied in the field of mining, can solve the problems of stratum environmental pollution, high labor intensity of workers, high cost, etc., and achieve the effects of low production cost, stable product quality, and easy decommissioning treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

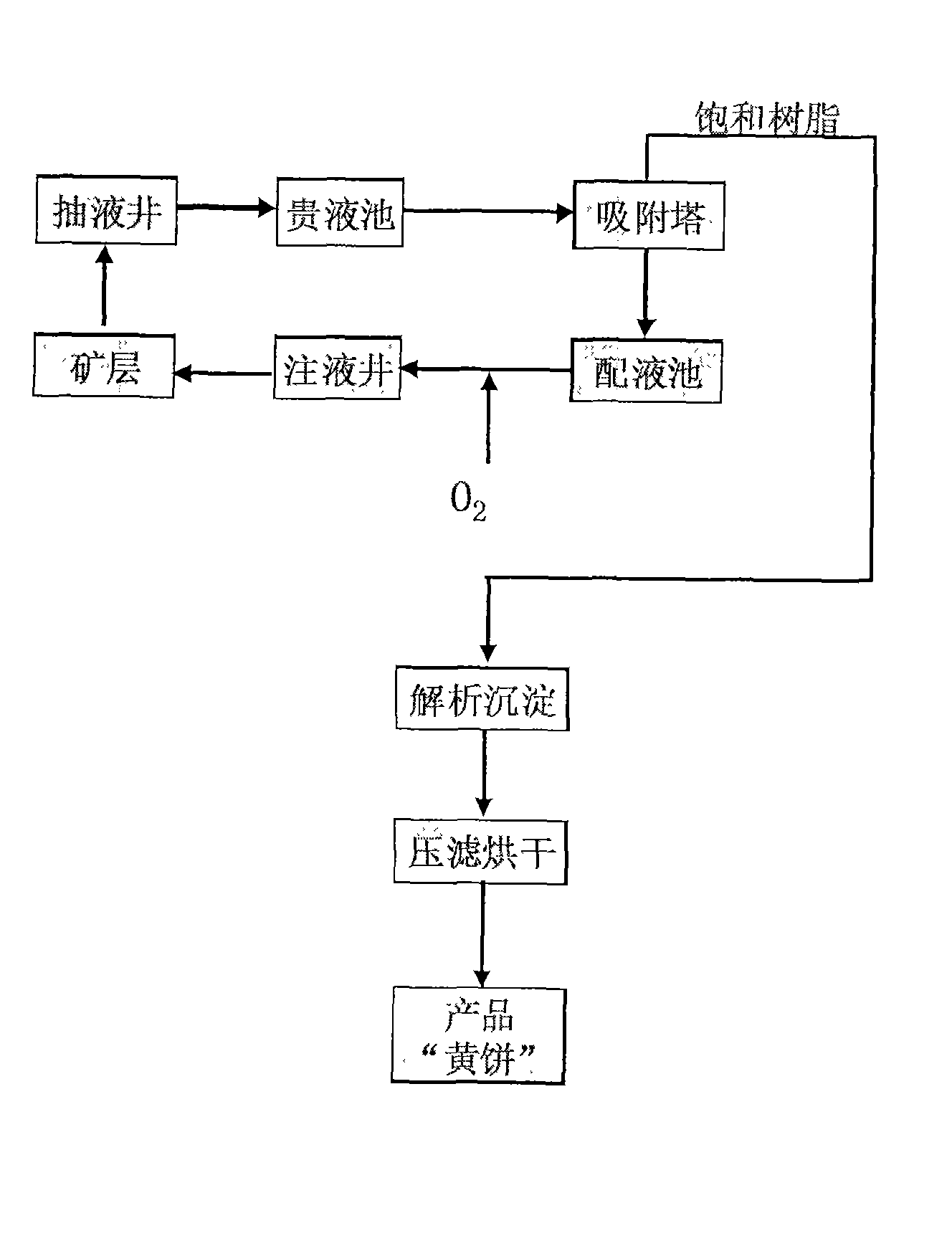

[0015] The implementation of the present invention will be described below in conjunction with the accompanying drawings.

[0016] As shown in the figure, the process flow of the present invention includes pumping the uranium-containing ore water in the ore seam to the precious liquid pool through the pumping well, and entering the adsorption tower for adsorption after sedimentation, and the saturated resin is produced through the processes of analysis and precipitation, pressure filtration, and drying. The product is "yellow cake", and the adsorption tail liquid is returned to the liquid distribution pool and recycled from the injection well to the ore layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com