Fabricating method of air vent vehicle body paste

A production method and a technology for air guide grooves, which are applied in the directions of drying solid materials, patterned paper, furnaces, etc., can solve problems such as easy generation of air bubbles, and achieve the effects of low cost, simple process, and flat and beautiful picture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

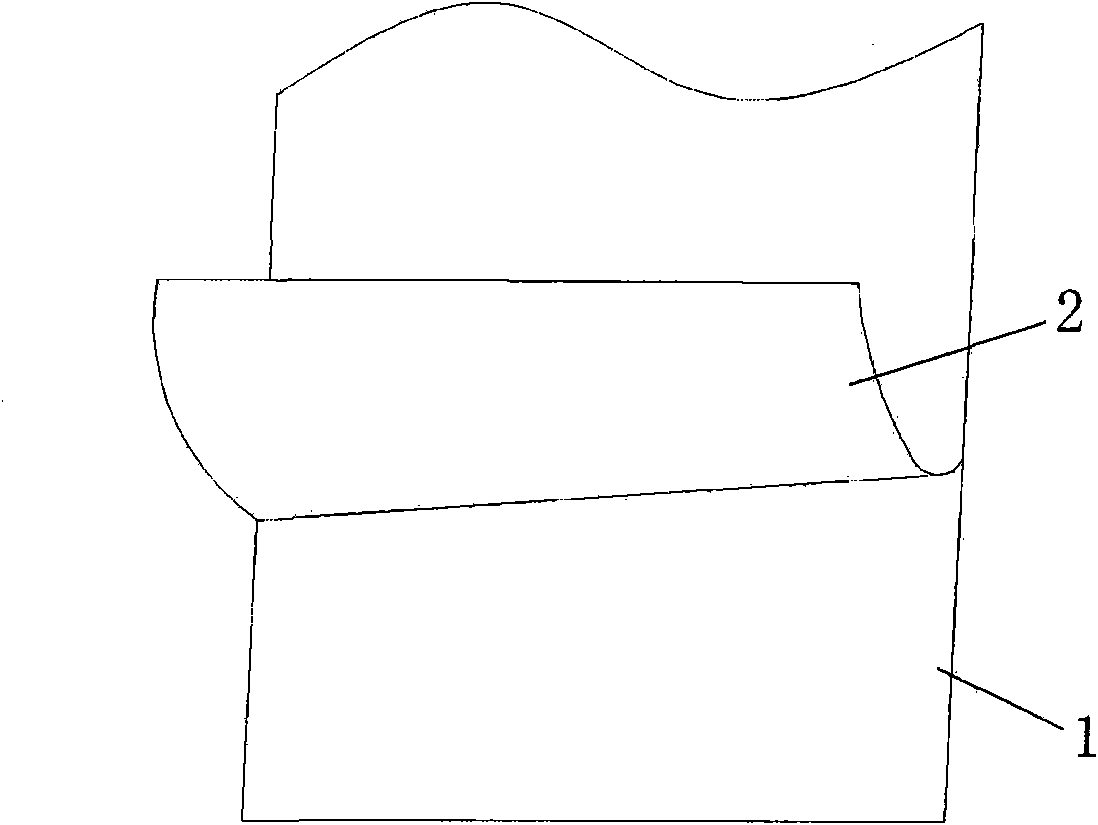

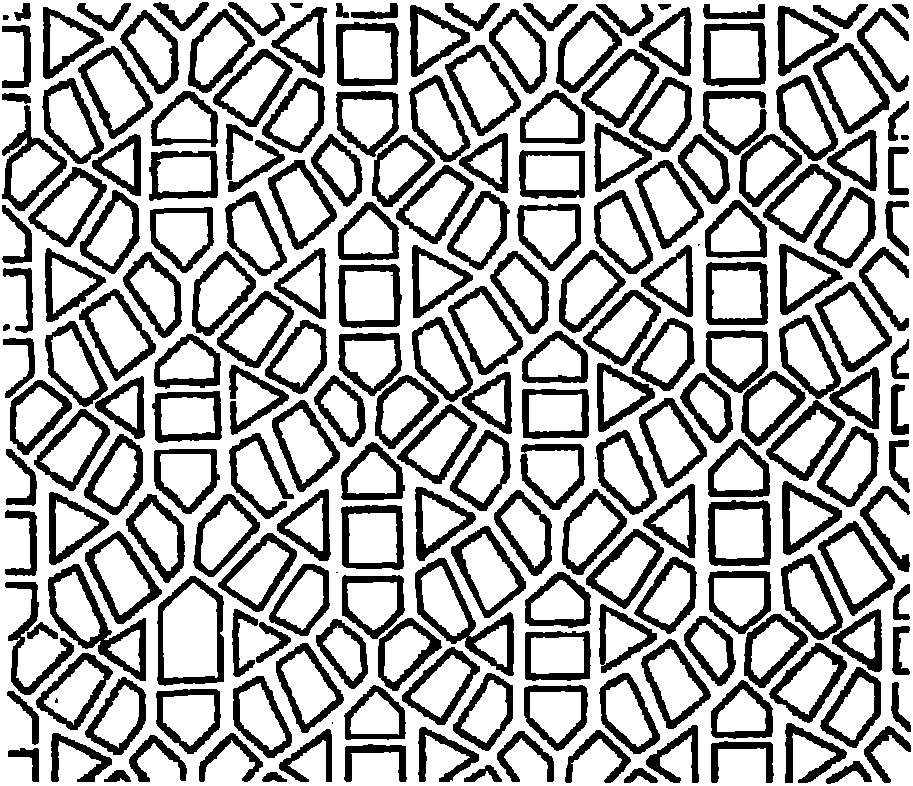

[0028] see figure 1 , as shown in the figure is a schematic structural diagram of a body sticker with an air guide groove, including a PVC film layer 1, a release paper layer 2 bonded to the PVC film layer, and a PVC film layer 1 and a release paper layer 2 A pressure-sensitive glue layer is coated between them, and the PVC film layer 1 and the release paper layer 2 are all provided with leather grain patterns on the pressure-sensitive glue layer (see image 3 ), if air bubbles accumulate in the film during use, the air bubbles can be smoothly discharged through the leather grain grooves, and the film screen is smooth and beautiful.

[0029] The specific production method is as follows:

[0030] 1) Put the base paper on the material rack of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com