Eccentric moment adjustable hydraulic vibration pile hammer

A technology of eccentric moment and hydraulic vibration, which is applied in the direction of sheet pile wall, building, foundation structure engineering, etc., to achieve obvious technological advancement, strong practicability, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and typical embodiments.

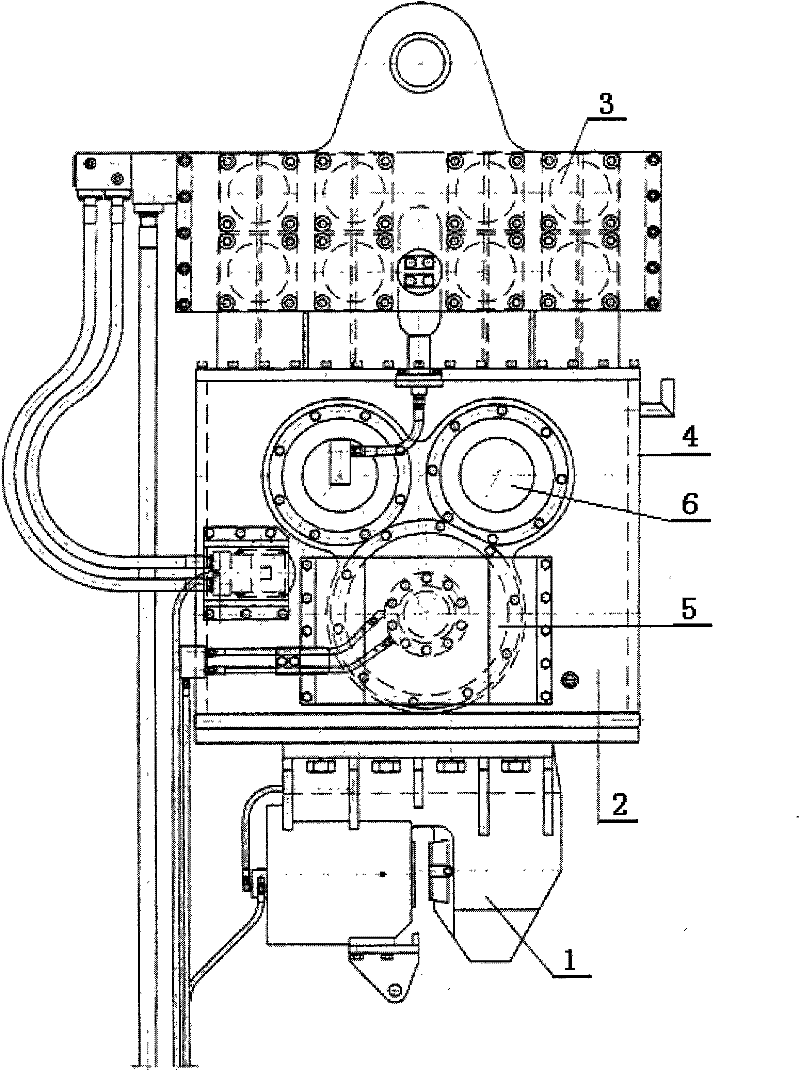

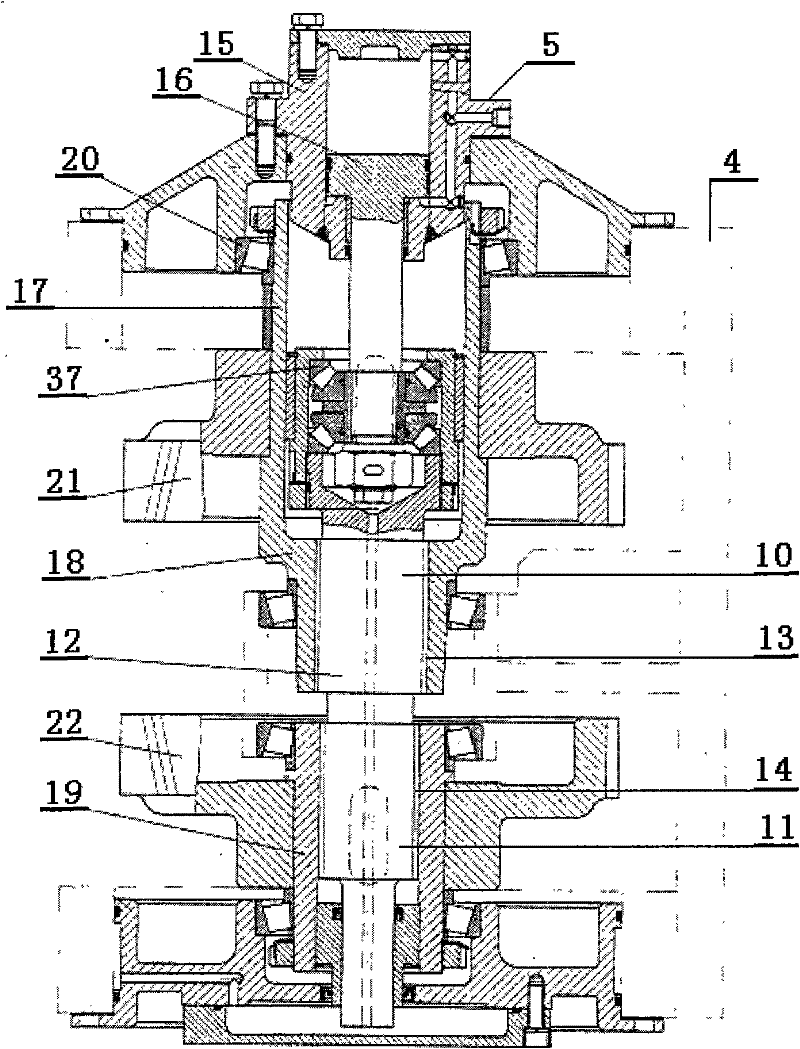

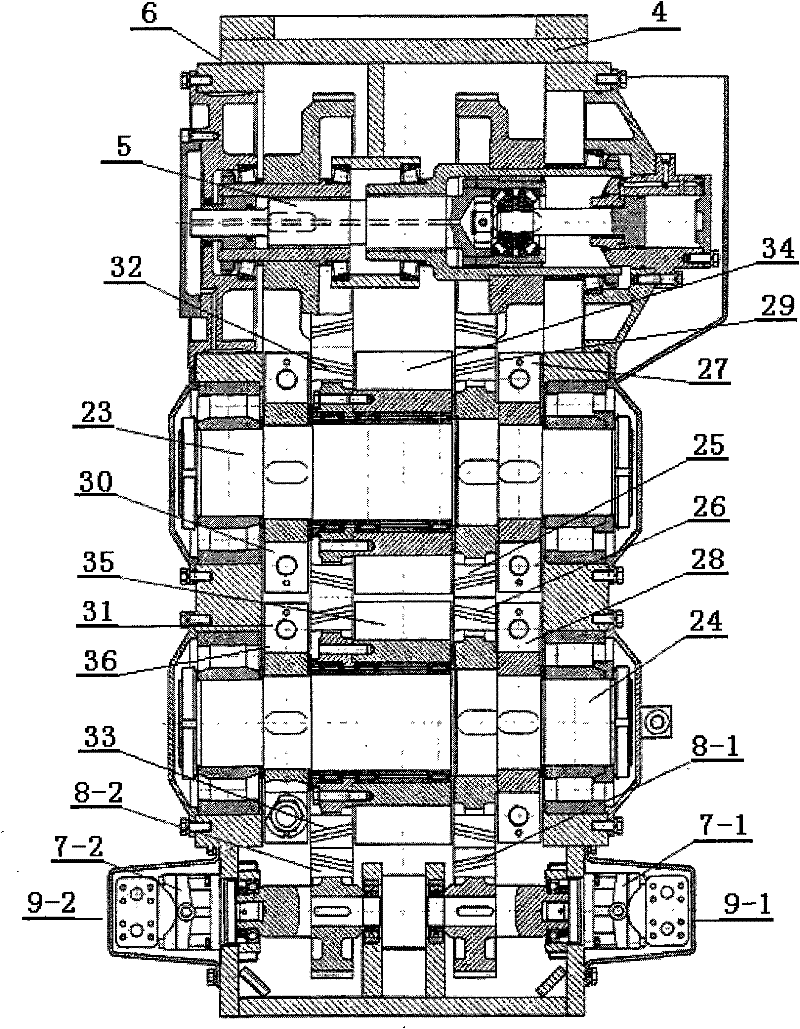

[0025] exist figure 1 , figure 2 and image 3Among them, the main body of the hydraulic vibrating pile hammer with adjustable eccentric moment of the present invention includes a hydraulic drive system 1, a vibrator 2 and a vibration damping mechanism 3, and the feature is that the vibrator 2 includes a box 4 and a box 4 The internal eccentric moment adjustment mechanism 5, the vibration dividing mechanism 6 and the hydraulic drive mechanism 9 including the hydraulic motor 7 and the driving gear 8, wherein: the eccentric moment adjustment mechanism 5 includes a larger end 10 and a smaller end 11 The adjustment shaft 12 is composed of a front rectangular helical external spline 13 fixedly arranged on the larger end 10 of the adjustment shaft 12 and a rear rectangular helical external spline 14 arranged on the smaller end 11, matching the insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com