Sprocket for chain

A sprocket and chain technology, applied in the direction of belts/chains/gears, transmission chains, portable lifting devices, etc., can solve problems such as hindering the smooth meshing of rollers and sprockets, chain vibration, and increased noise, etc., to achieve Engagement sound reduction, vibration reduction and noise, vibration and noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

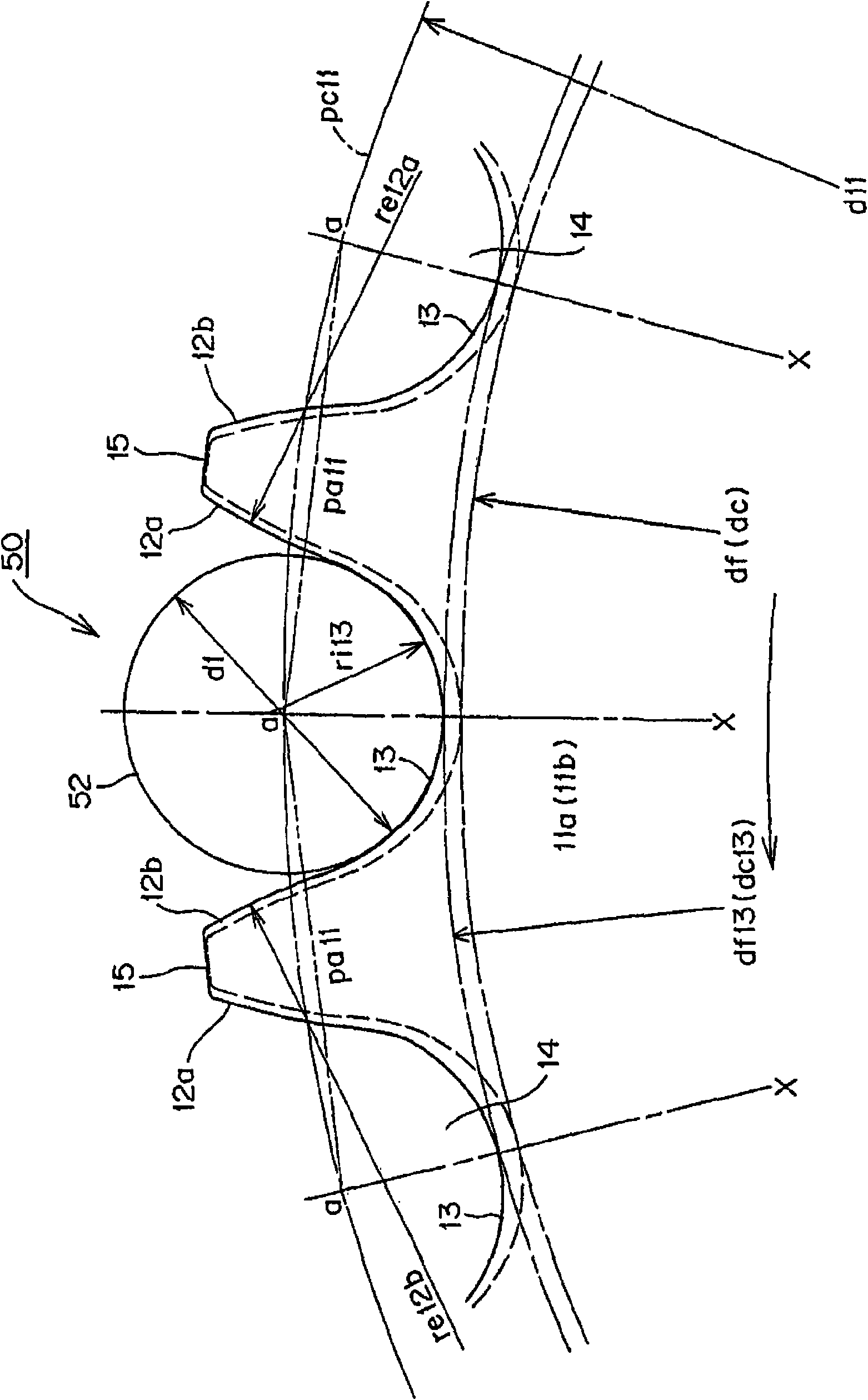

[0080] The chain sprocket according to the first embodiment of the present invention will be described below.

[0081] have figure 1 The tooth-shaped standard roller chain sprockets (hereinafter simply referred to as sprockets) 11 a are applied to the standard roller chain 50 .

[0082] In the sprocket 11a, a plurality of teeth 15 are formed in tooth grooves 14 continuous with the dedendum portion 13 through the opposing tooth surfaces 12a and 12b. In addition, in figure 1 In , for comparison, the ISO tooth shape (standard tooth shape) is shown by a dotted line.

[0083] Such as figure 1As shown, the tooth shape of the sprocket 11a is formed so that the tooth surface 12a on the front side in the rotation direction of the sprocket 11a and the tooth surface 12b on the back side in the rotation direction of the sprocket 11a are connected to the rotation center O (not shown) of the sprocket 11a and each tooth. The dedendum center line X at the center of the root portion 13 ...

Embodiment 2

[0094] The chain sprocket according to the second embodiment of the present invention will be described below.

[0095] In addition, the tooth profile of the chain sprocket 11b of Example 2 is the same as figure 1 The tooth profile of the illustrated embodiment 1 is the same, so the explanation is omitted.

[0096] Compared with the above-mentioned embodiment 1 of the present invention having two kinds of pitch angles θ-Δθ and θ+2Δθ of different sizes, the pitch angle of the teeth of the sprocket 11b only has three kinds of tooth shapes with different sizes The pitch angle is different. As described above, for the convenience of the following description, the tooth profile pitch angle θ determined by the formula θ=360° / z is called a standard pitch angle.

[0097] The sprocket 11b has three types of tooth profile pitch angle θ (standard pitch angle θ), θ+Δθ, and θ−Δθ with different sizes. That is, the tooth profile pitch angle θ+Δθ is larger than the standard pitch angle θ ...

Embodiment 3

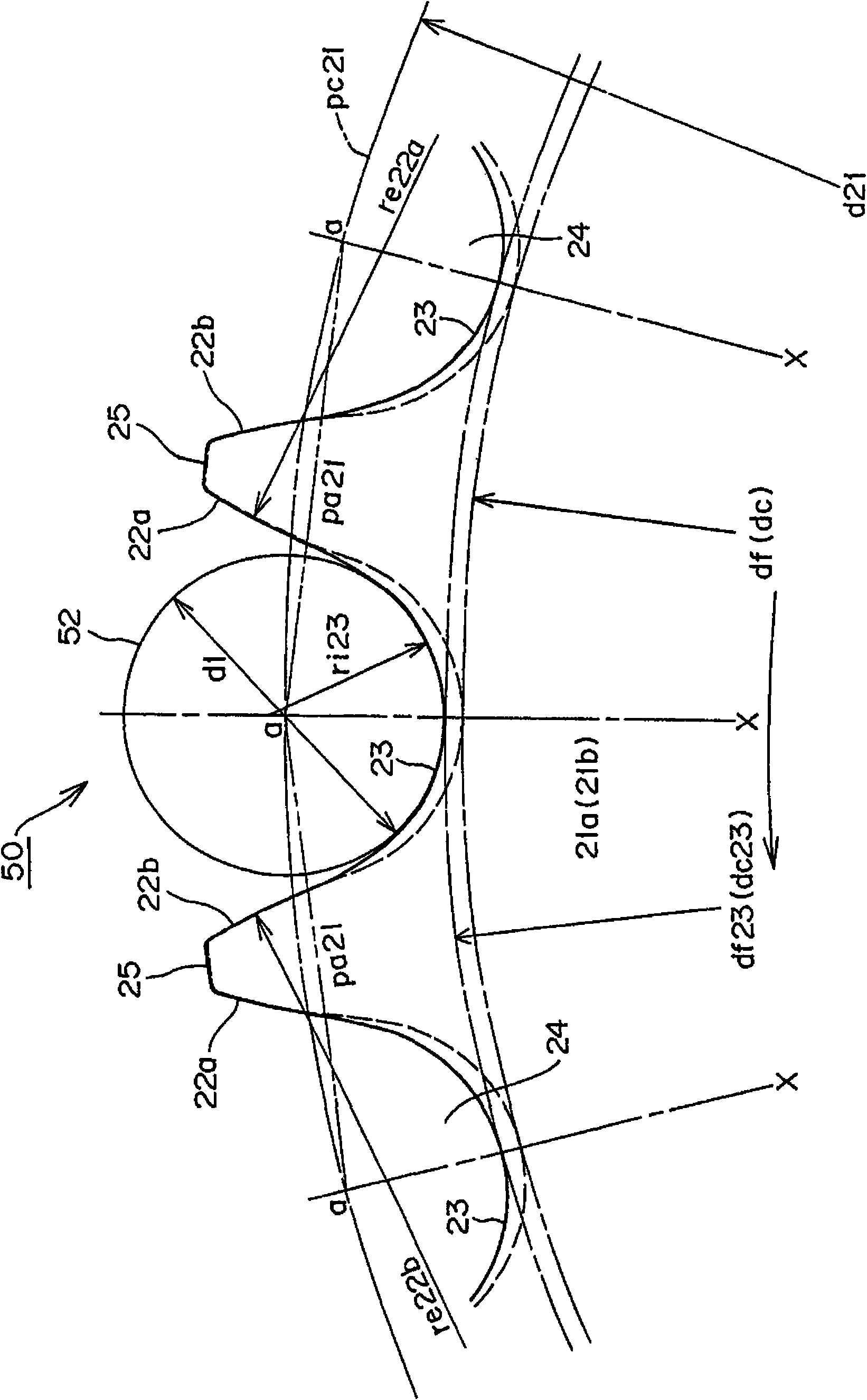

[0103] Next, a chain sprocket according to Embodiment 3 of the present invention will be described.

[0104] have figure 2 The shown tooth-shaped standard roller chain sprocket (hereinafter simply referred to as a sprocket) 21 a is a sprocket applied to the standard roller chain 50 .

[0105] In the sprocket 21a, a plurality of teeth 25 are formed in tooth grooves 24 continuous to the dedendum portion 23 by opposing tooth surfaces 22a, 22b. In addition, in figure 2 In , for comparison, the ISO tooth shape (standard tooth shape) is shown by a dotted line.

[0106] Such as figure 2 As shown, the tooth shape of the sprocket 21a is formed so that the tooth surface 22a on the front side in the rotation direction of the sprocket 21a and the tooth surface 22b on the back side in the rotation direction of the sprocket 21a are connected to the rotation center O (not shown) of the sprocket 21a and each tooth. The dedendum part center line X of the dedendum part 23 at the center o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com