Straight-way solar energy heat exchange heat collector

A solar, straight-through technology, applied in solar thermal devices, solar thermal energy, solar thermal power generation, etc., can solve the problems of high cost, difficult to heat, large temperature difference between inner and outer tubes, etc., and achieve the effect of high heat utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

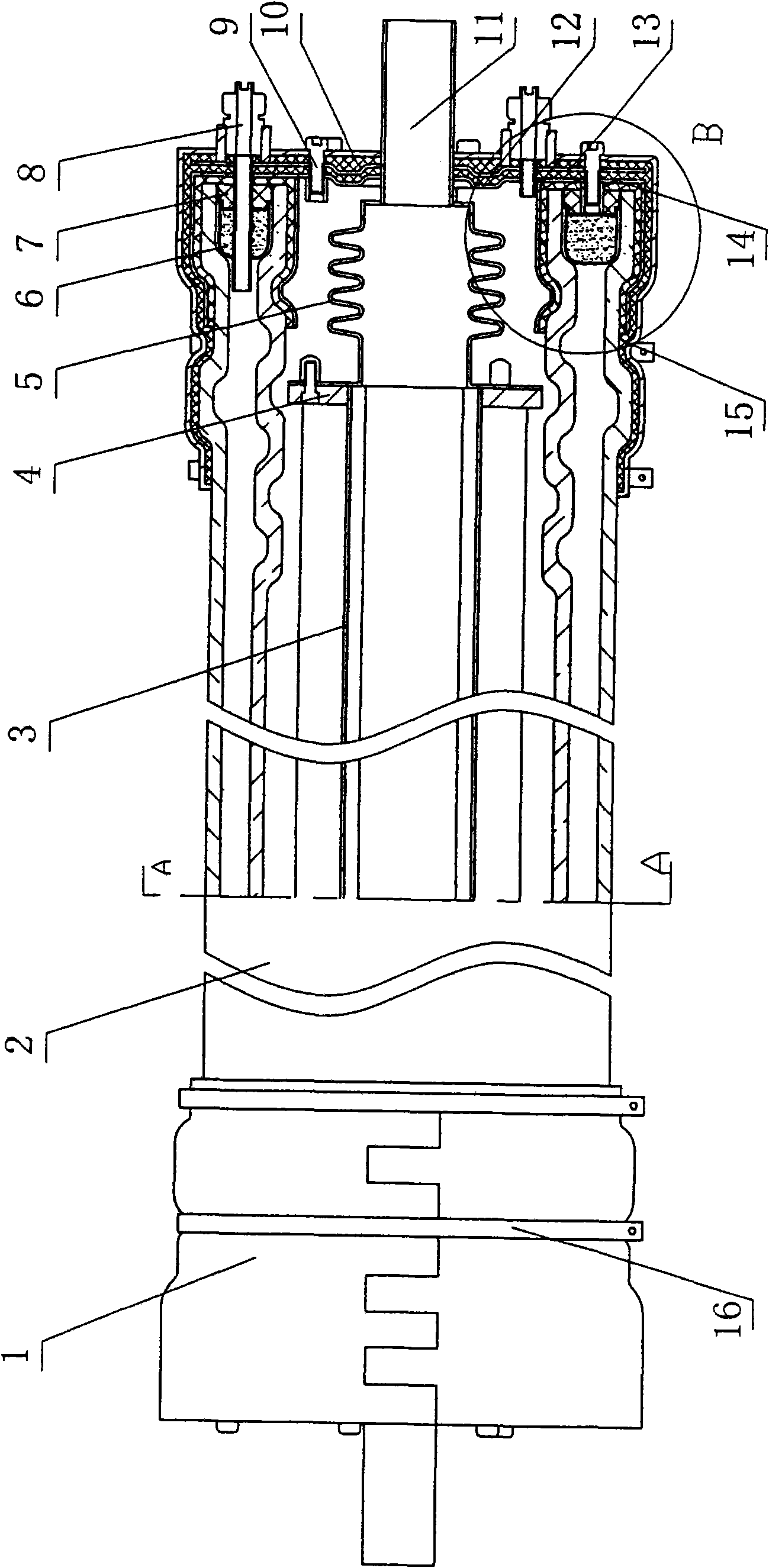

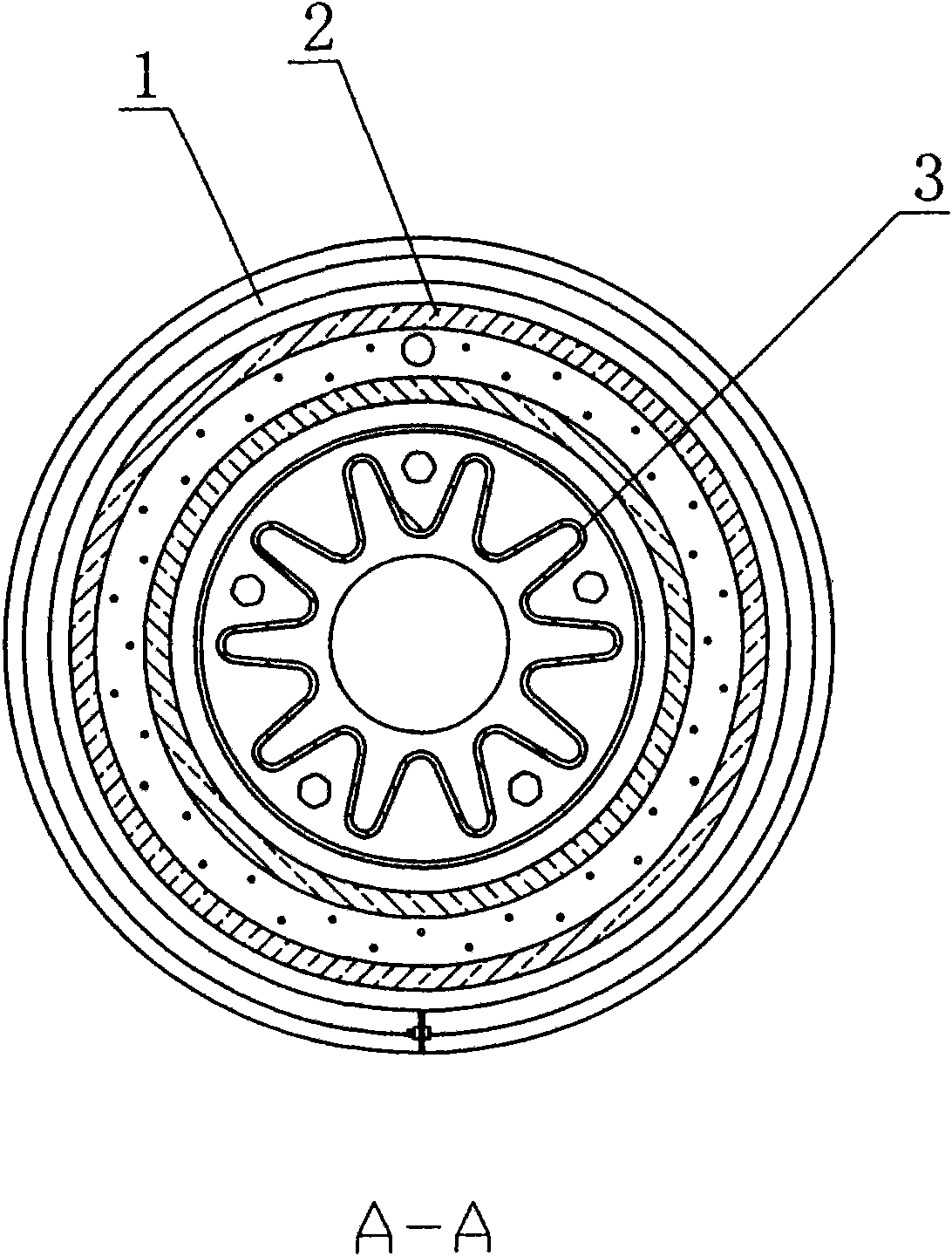

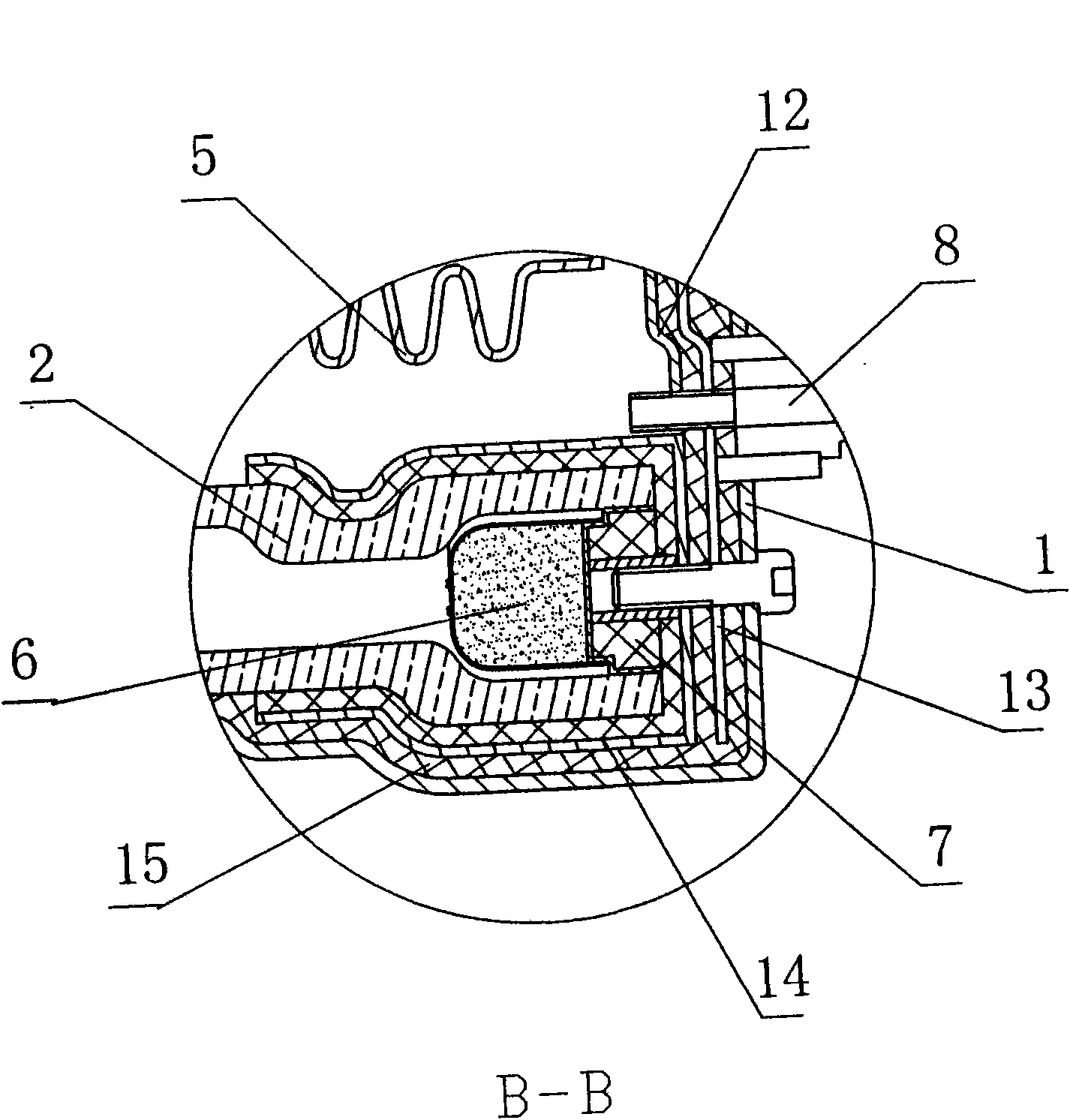

[0065] Refer to attached Figure 1-11 , the straight-through solar heat exchange and heat collection device includes a straight-through light-transmitting tube 2, a multi-curved metal heat exchange tube 3, a heat exchange tube head 4, a metal expansion joint 5, an adsorbent storage ring 6, a concave spacer sealing ring 7, a metal Snap ring 14, working fluid channel pipe 11, metal cover plate 12, sealing and fixing plate 13, clip-type shielding cover 1 and vacuum joint 8;

[0066] The two ends of the multi-curved metal heat exchange tube 3 are welded and fixed with the heat exchange tube head 4, the working medium passage tube 11 is connected with the heat exchange tube head 8, the multi-curved metal heat exchange tube 3 is provided with a metal expansion joint 5, and the working medium The channel tube 11 passes through the center of the metal cover plate 12, and the working medium channel tube 11 and the metal cover plate 12 are welded and sealed to form a multi-curved metal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com