Control method of alternative pressure of side guides of hot strip mill coiler

A technology of pressure control and side guide plate, applied in the direction of mechanical pressure/force control, control without feedback, general control system, etc., can solve the problems of thick strip steel clamping stop, uneven wear of guide plate, large operating load, etc. Reach the effects of reducing roll layer stagger defects, improving roll shape quality, and reducing edge damage defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The technical solutions of the present invention are further described below with reference to the accompanying drawings and embodiments.

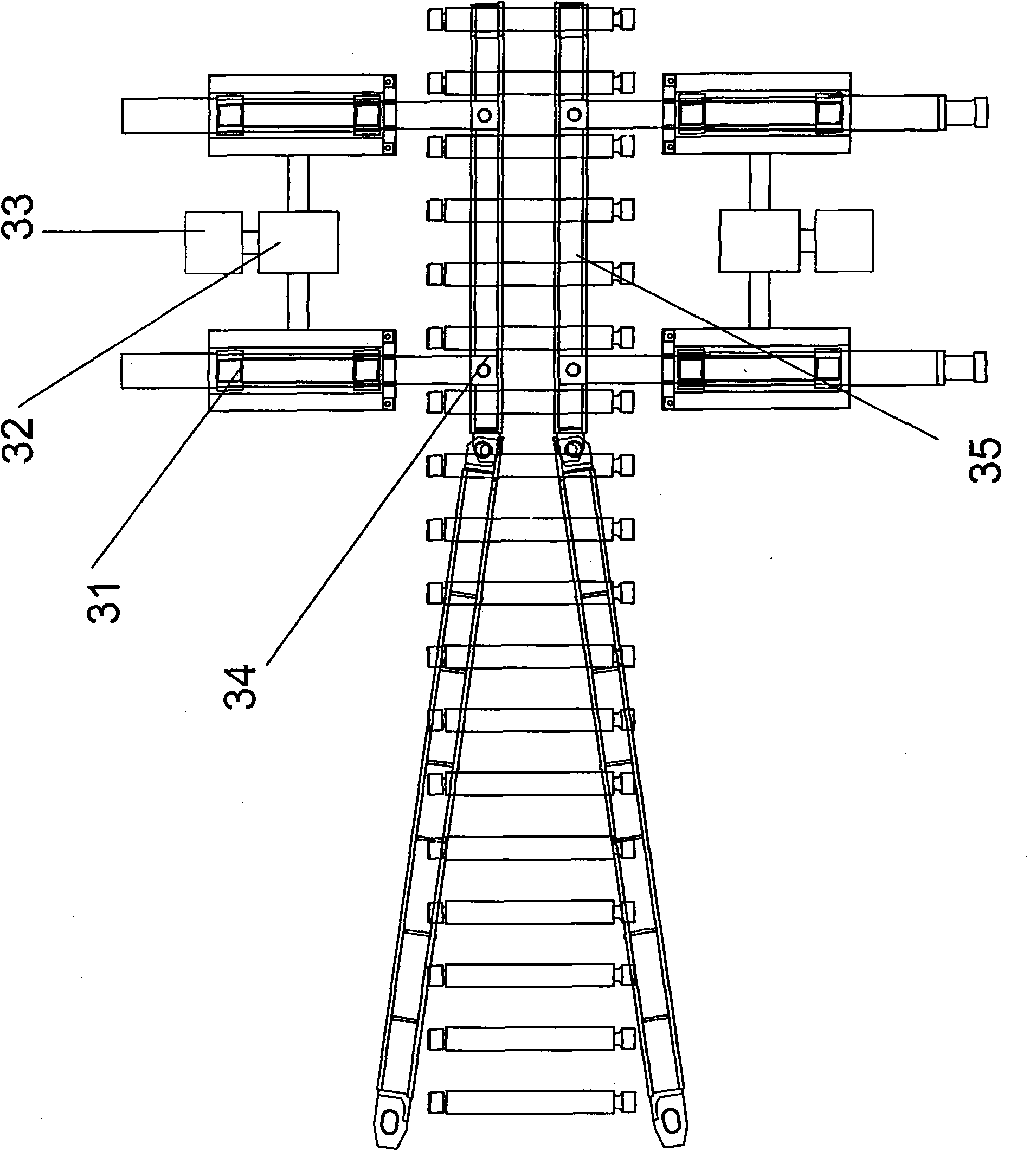

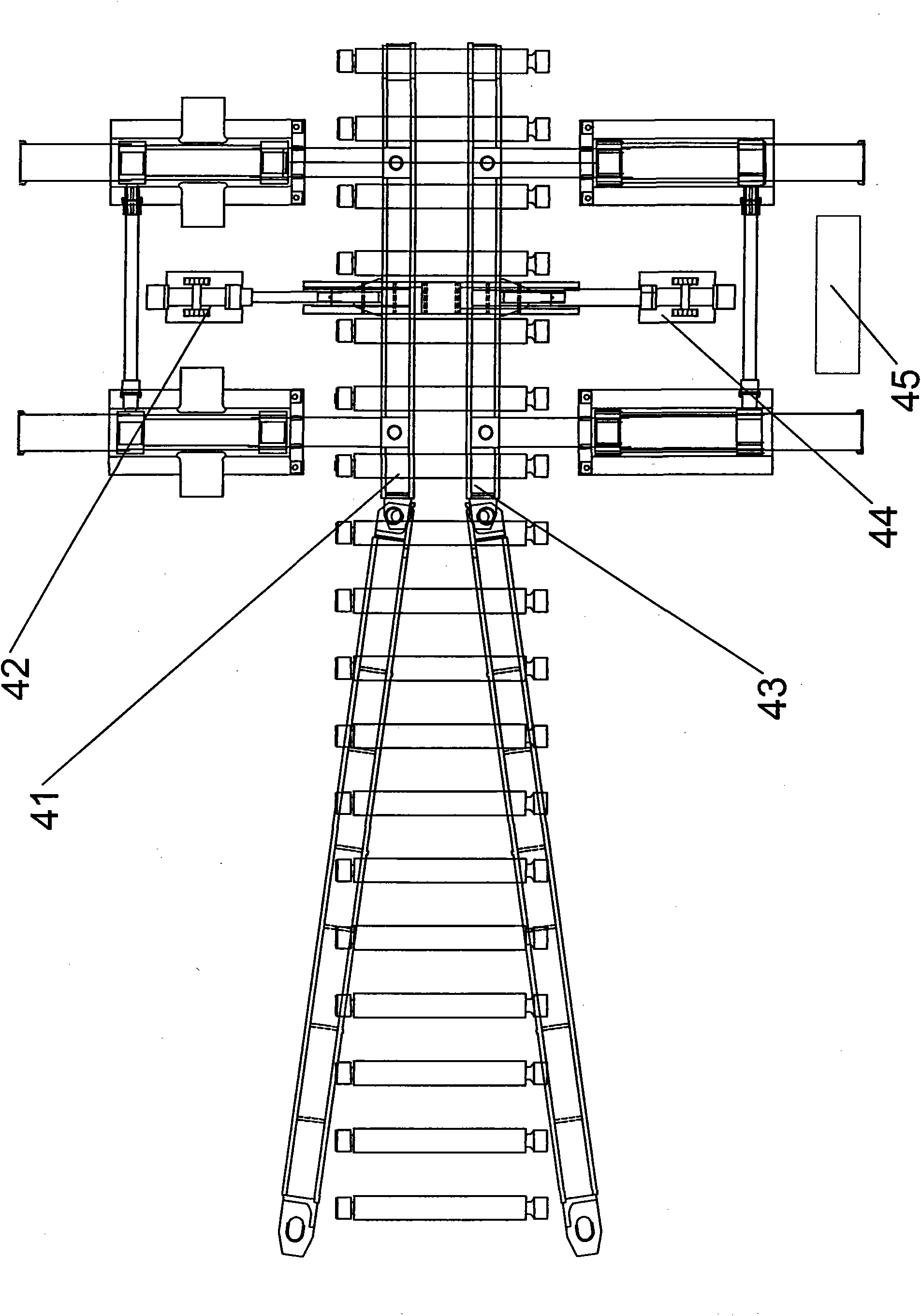

[0050] refer to image 3 , in order to realize the alternate pressure control method of the side guide plate according to the present invention, the side guide plate structure of the hot rolling coiler has been improved somewhat compared with the current one. The pressure sensor is installed in the valve frame, the position sensor is installed in the long stroke oil cylinders 42 and 44, the related systems of the transmission side guide plate 41 and the operation side guide plate 43 are equipped with pressure and position sensors, and the valve frame 45 is equipped with a pressure sensor.

[0051] refer to Figure 4 , Figure 4 It is a hardware control schematic diagram to realize the alternate control of position and pressure, which is divided into three parts: transmission system 100, side guide plate control system 200, and pin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com