Array micro audio directional transducer

A transducer and micro-acoustic technology, applied in the field of MEMS-based transducers and ultrasound, can solve problems such as poor directivity, low receiving sensitivity, and low output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

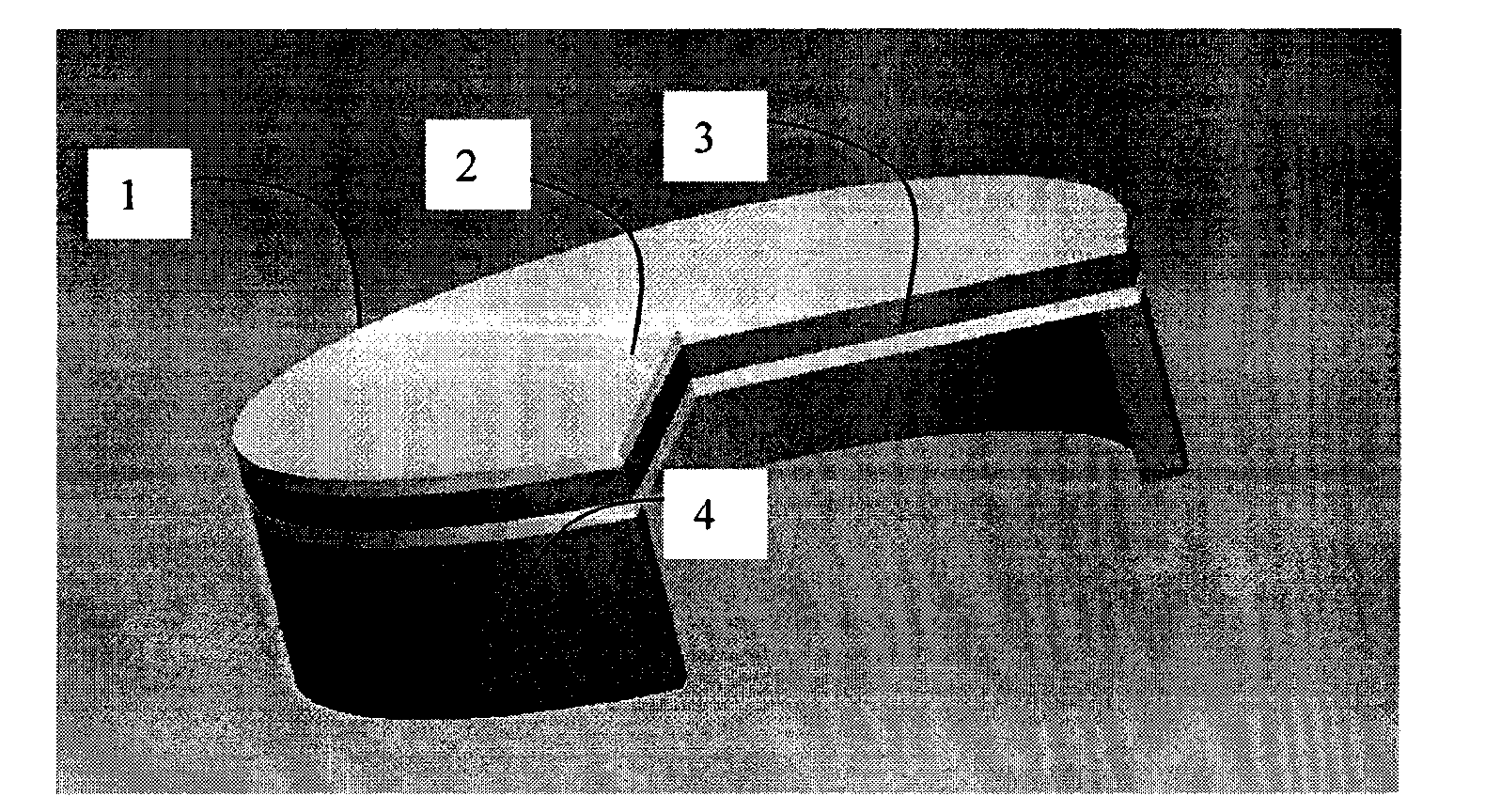

[0035] figure 1 Shown is an embodiment of the circular array unit in the present invention, as follows figure 1 As shown, the array unit consists of four parts, the upper electrode 1 , the lower electrode 3 , the ultrasonic radiation material 2 and the base 4 . The upper electrode 1 and the lower electrode 3 fix the radiation material 2 and serve as positive and negative electrodes of the array unit. The upper electrode 1 and the lower electrode 3 are formed by sputtering. This process ensures the stability of the conduction on both sides of the film and the small parasitic resistance. The vibration radiation material 2 is a piezoelectric film material. The piezoelectric film material can be a piezoelectric ceramic film material or a piezoelectric polymer film material. The radiation material 2 requires high mechanical response and electrical response sensitivity. Impedance is required to match air impedance as closely as possible. When a voltage is applied to the electrode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com