Fixing device combination

A technology for fixing devices and installation grooves, which is applied in the direction of elastic/clamping devices, electric solid devices, circuit layout on support structures, etc., and can solve the problems of increasing material costs and assembly costs, buckle buckles not tight, installation buckles, etc. It eliminates the risk of circuit board short circuit, reduces the cost of materials, and reduces the cost of assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

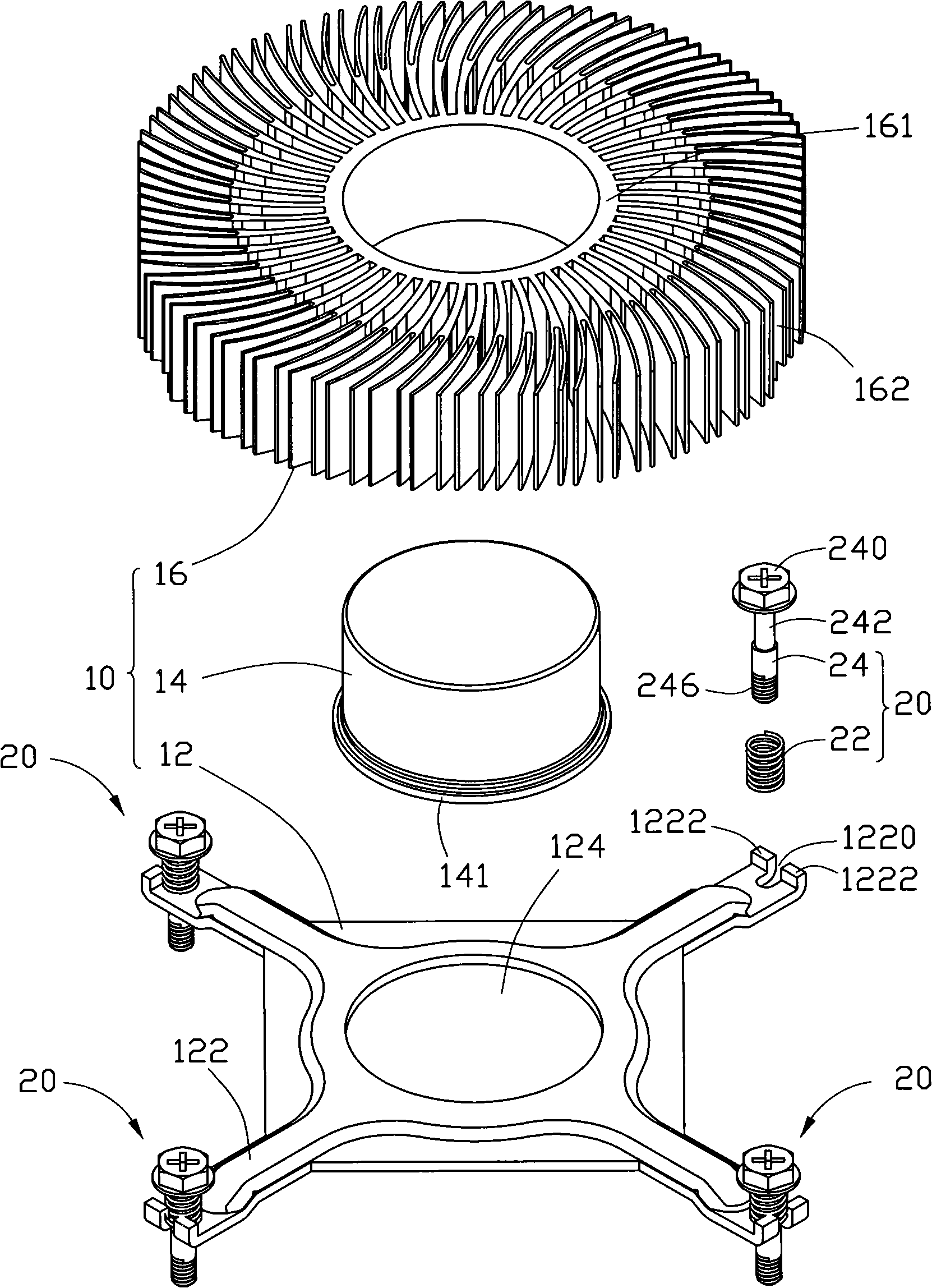

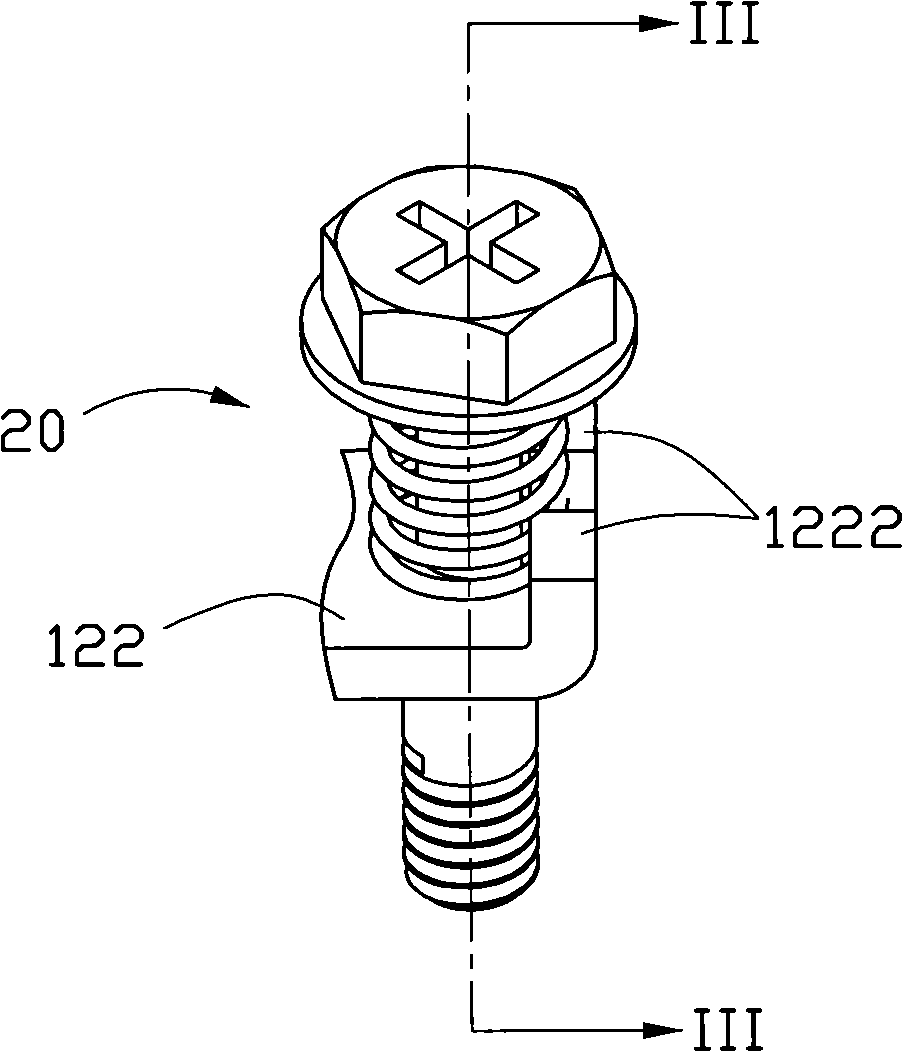

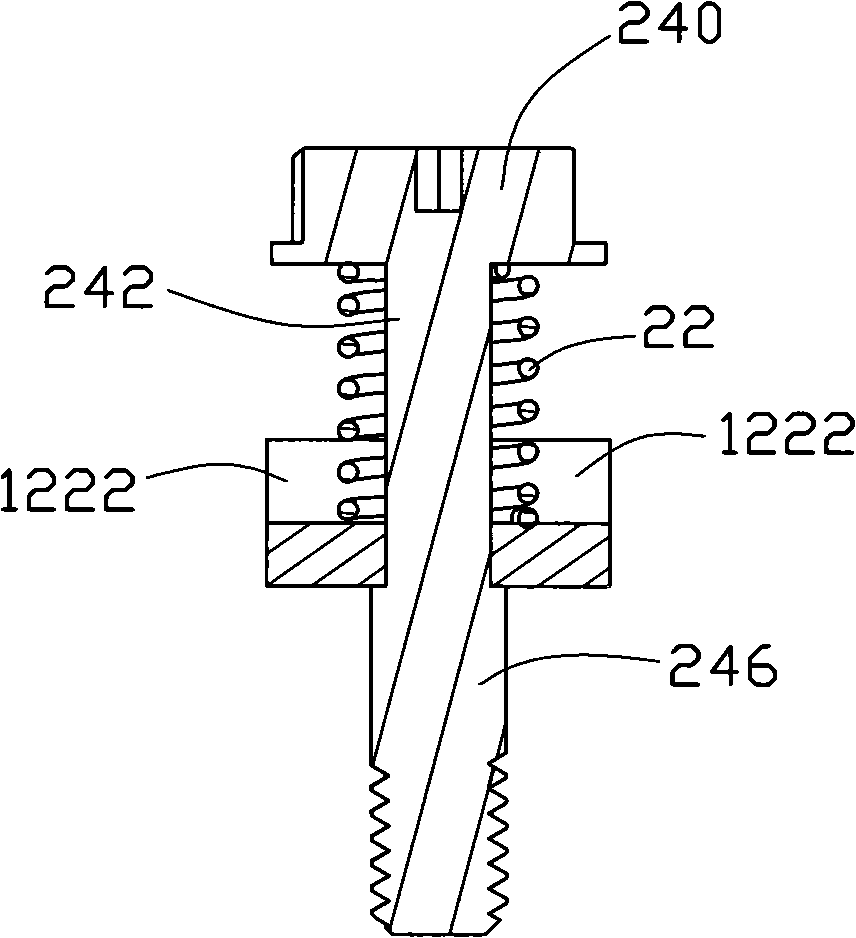

[0014] see Figure 1 to Figure 3 , the fixing device combination includes a heat sink 10 and several spring fasteners 20 .

[0015] The heat sink 10 includes a substrate 12 , a heat transfer column 14 and a heat sink 16 . The base plate 12 is square, with a through hole 124 formed in the center thereof, and a buckle ear 122 extending outward from four corners of the base plate 12 . The base plate 12 is integrally stamped from sheet metal parts, so the manufacturing process is simple and the production efficiency is high. The heat transfer cylinder 14 is cylindrical, and the bottom thereof protrudes outward to form a protruding ring 141 . The outer diameter of the protruding ring 141 is larger than the diameter of the through hole 124 . In this embodiment, the heat transfer cylinder 14 is a solid cylinder, such as a copper cylinder. The radiator 16 includes a hollow circular cylinder 161 in the middle and a plurality of cooling fins 162 disposed around the cylinder 161 . Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com