Novel screw type solid-liquid separating machine

A solid-liquid separator and spiral technology, applied in the direction of filtration separation, separation method, fixed filter element filter, etc., can solve the problems that cannot be applied to large and medium-sized sewage treatment plants, reduce the durability and practicability of the device, etc. , to achieve the effect of improving durability and practicability, no vibration, and solving wear problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments. These examples should be understood as only for illustrating the present invention but not for limiting the protection scope of the present invention. After reading the contents of the present invention, those skilled in the art can make various changes or modifications to the present invention, and these equivalent changes and modifications also fall within the scope defined by the claims of the present invention.

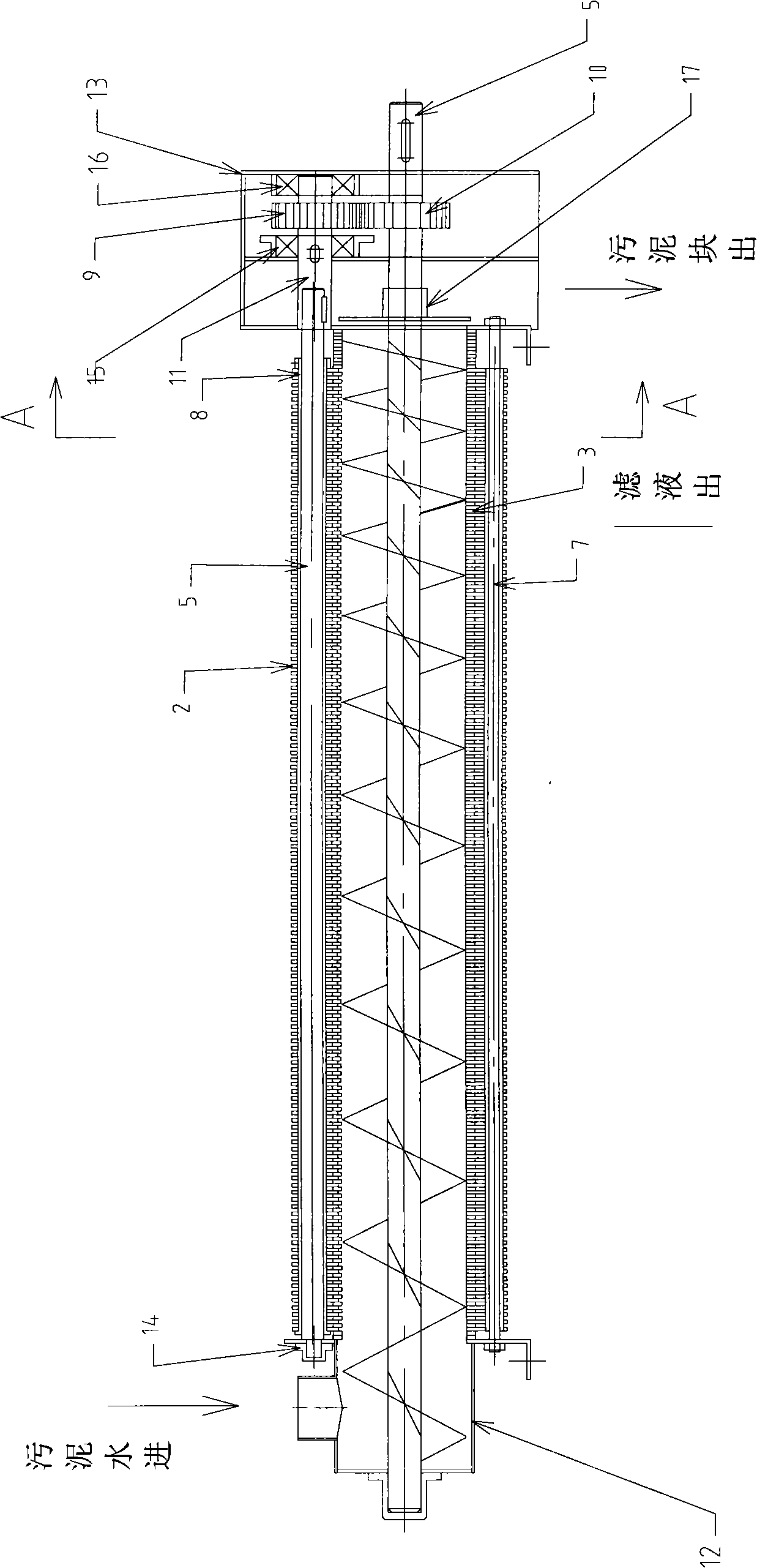

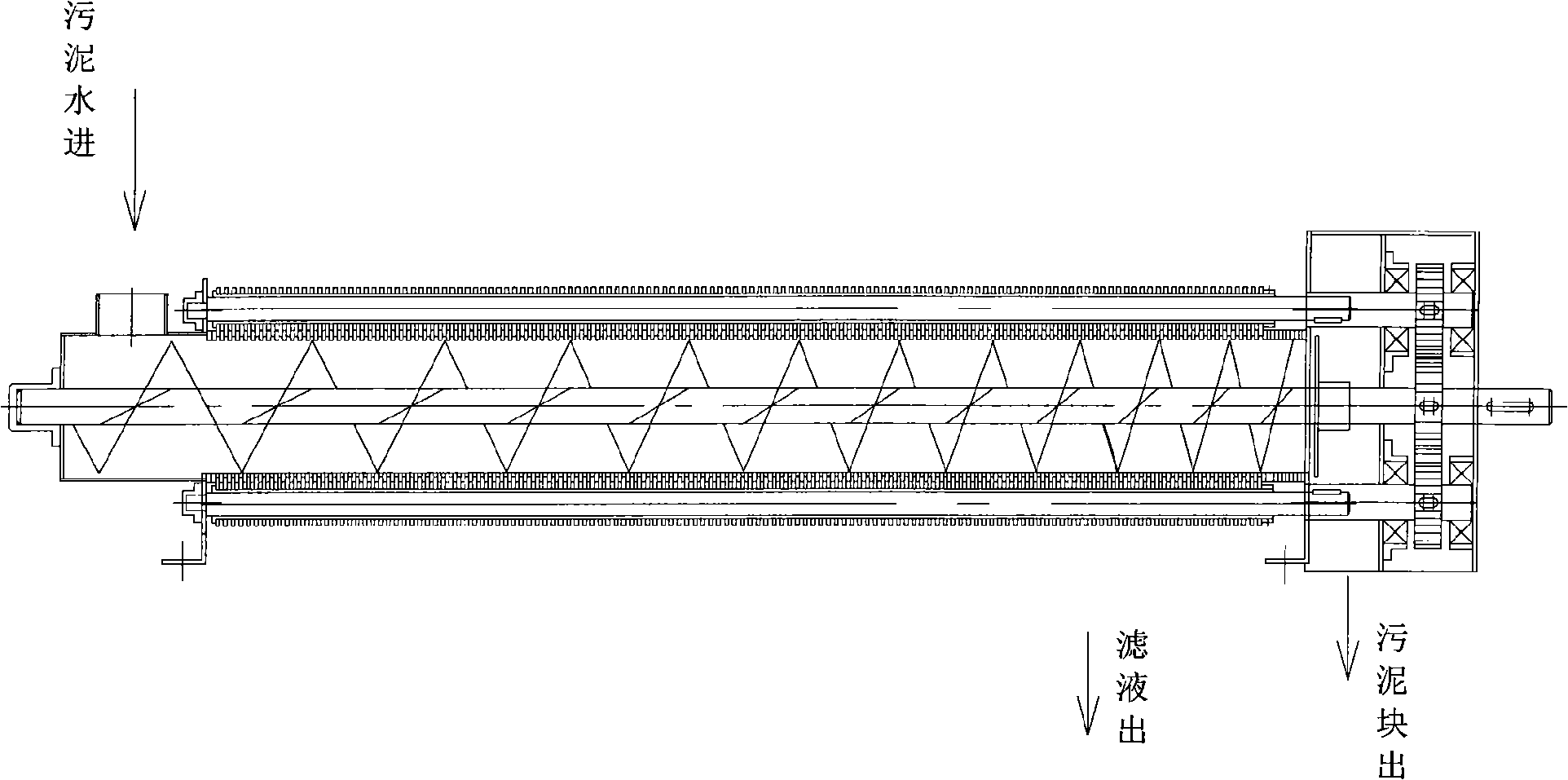

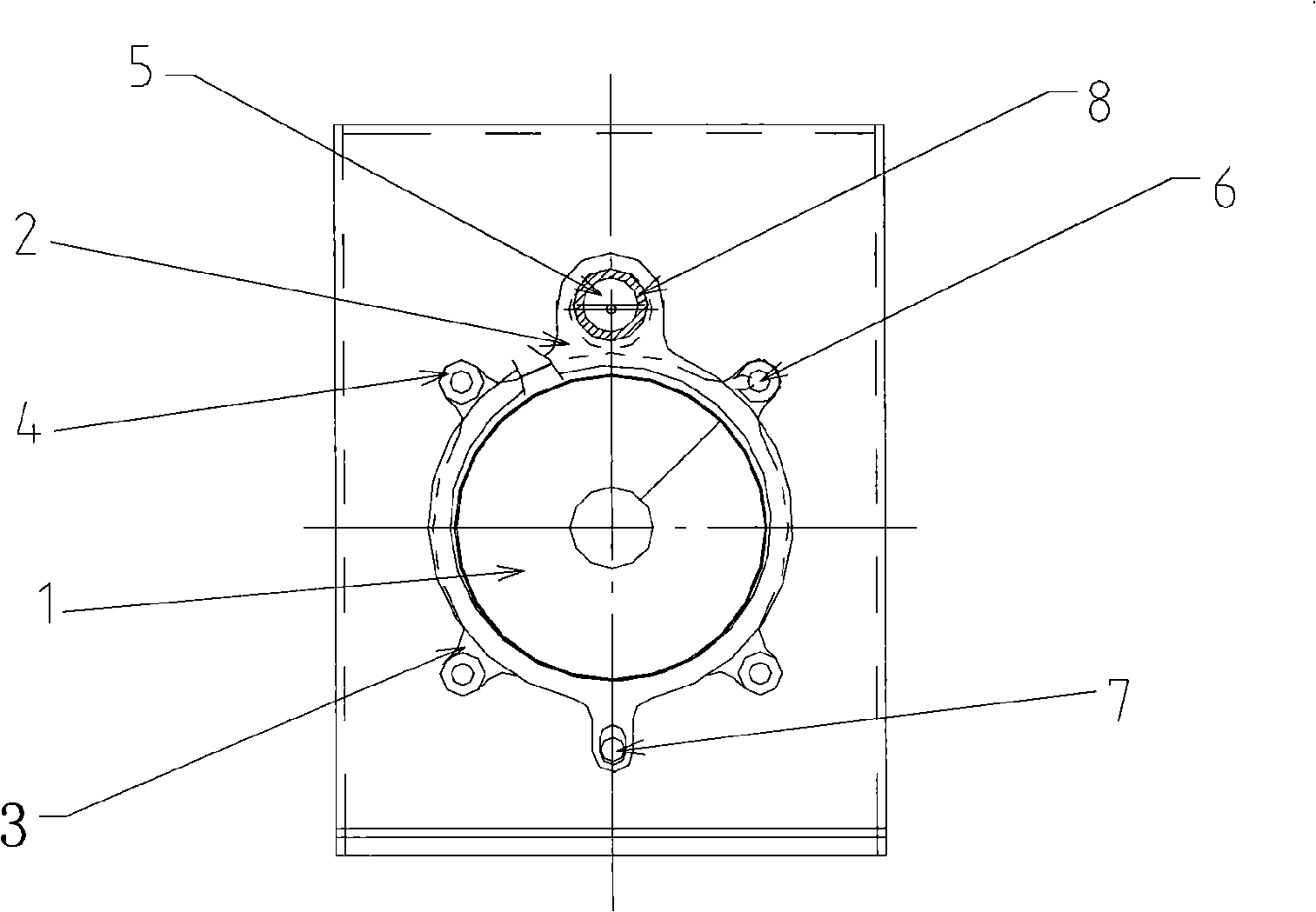

[0021] Such as figure 1 , 3 As shown, the spiral solid-liquid separator proposed by the first preferred embodiment of the present invention includes a screw shaft 1, and the diameter of the blade of the screw shaft is covered with a plurality of circular laminations, which are composed of fixed rings 3, Composed of moving ring 2 and adjusting piece, the arrangement of multiple circular laminations is that there is an adjusting pie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com