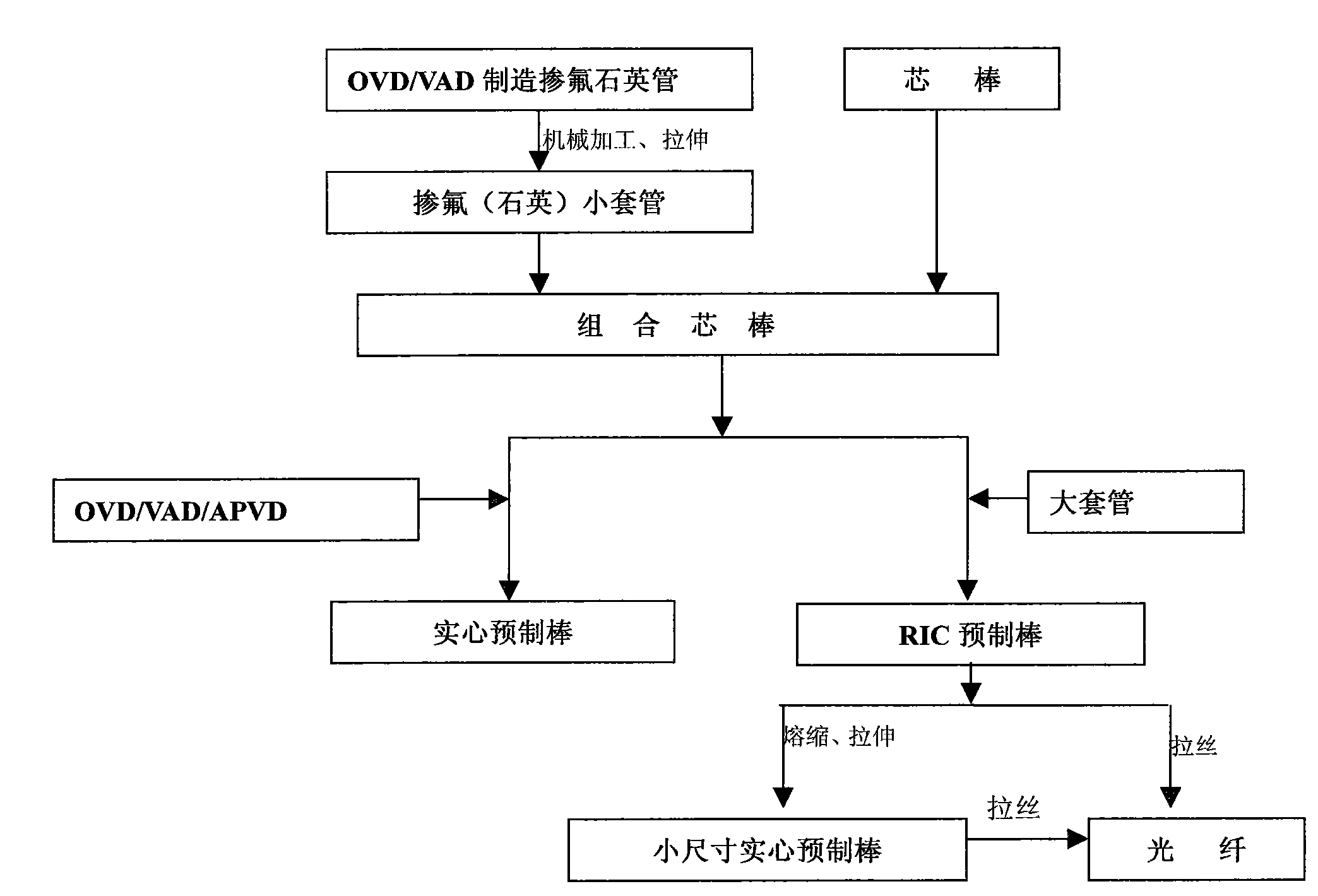

Optical fiber perform and manufacture method thereof

A technology of optical fiber preform and manufacturing method, which is applied in the field of optical communication, can solve the problem of insufficient bending performance of optical fiber, and achieves the effects of low cost, remarkable effect and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

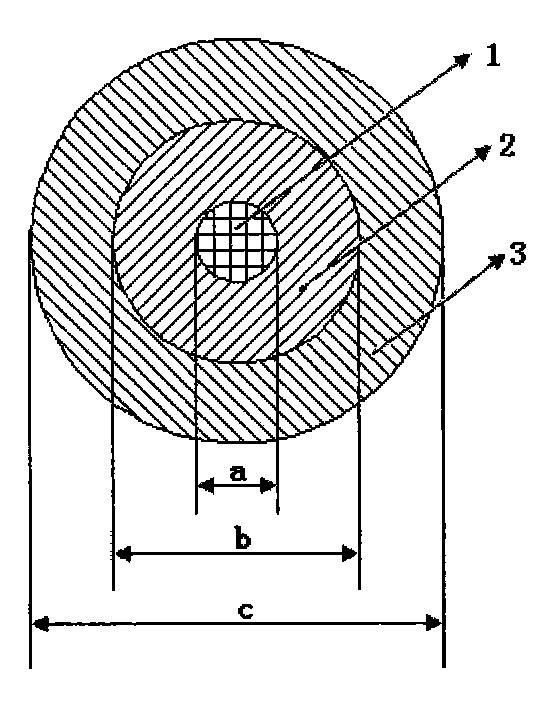

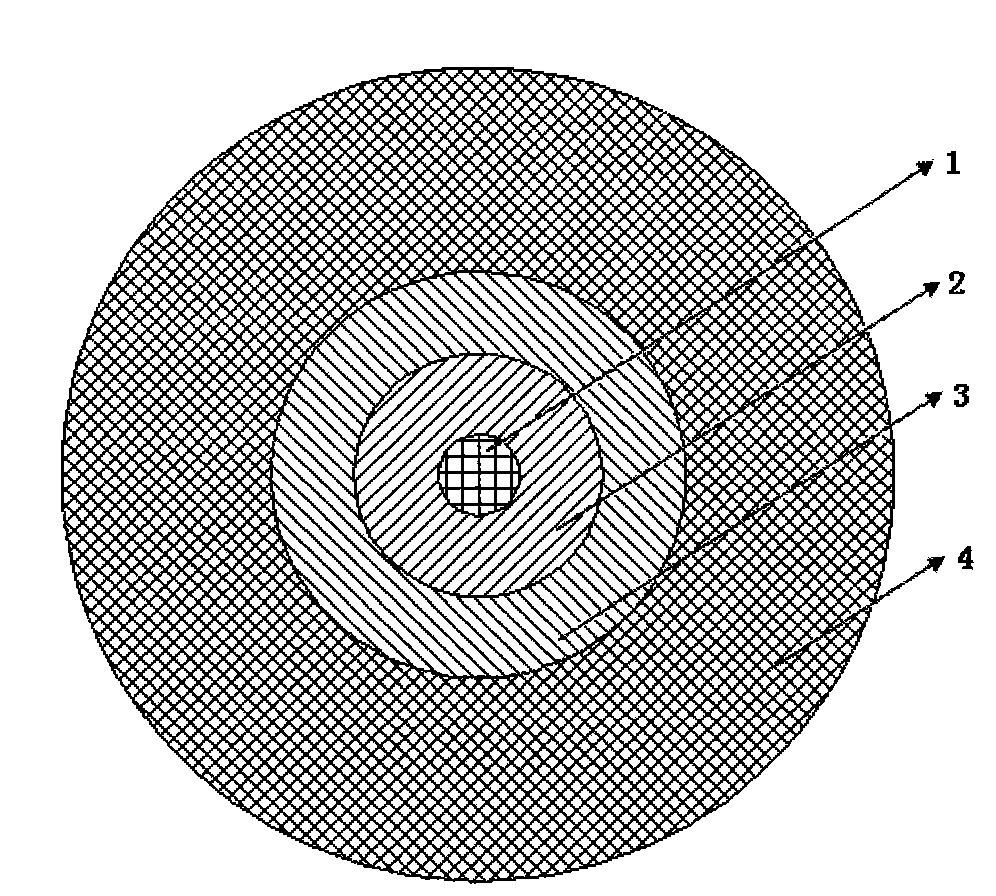

Embodiment 1

[0060] The G.652 low water peak optical fiber core rod is prepared by PCVD process, which has an optical fiber core rod core layer 1 and an optical fiber core rod partial cladding layer 2; the outer diameter of the liner used is 31 mm, the wall thickness is 2 mm, and the refractive index of the core rod rate profile as Figure 5 As shown; the fluorine-doped quartz tube prepared by the OVD process is stretched into a small casing 3 of the required size after mechanical processing, and the OH content in the small fluorine-doped quartz casing is 10-500ppb; the optical fiber core rod and The small fluorine-doped quartz sleeve is melted and shrunk together to make a combined mandrel, and then the surface is etched with hydrofluoric acid (HF). and a quartz tube with an inner diameter (ID) as a large casing 4, which is assembled by RIC process Figure 4 In the shown RIC process prefabricated rod, the combined core rod 5 is set in the large sleeve 4 and the center of the combined cor...

Embodiment 2

[0067] Prepare G.652 low water peak optical fiber core rod and mother rod by VAD process, using H 2 / O 2 Extend it into the RIC mandrel of the required core diameter by flame, then use hydrofluoric acid (HF) to etch the surface into the mandrel of the target outer diameter, and use the small sleeve and scheme in Example 1 to make the combined mandrel , a large quartz sleeve with an outer diameter of 200 mm and an inner diameter of 53 mm is used to assemble a RIC preform. The relevant parameters of the combined mandrel are shown in Table 3. On the stretching tower, the combined mandrel and the large sleeve are melted together and stretched into a small-sized solid preform with an outer diameter of 80 mm before drawing. The optical fiber coating material for single-mode optical fiber production is used. The drawing speed is 1500 m / min, the diameter of the bare fiber is 124 μm to 126 μm; the main parameters of the drawn fiber are shown in Table 4.

[0068] Table 3. Relevant pa...

Embodiment 3

[0074] In the VAD or OVD manufacturing cladding deposition process, due to the use of H 2 / O2 Therefore, the OH pollution to the core rod is obvious; in the plasma spraying technology, not only the OH content in the deposited glass is relatively high, but also the OH in the environment will be adsorbed on the target rod and diffuse inward; once The diffusion of OH into the core layer of the preform will cause the increase of the water peak of the optical fiber. Whether OH can diffuse inward into the core layer of the preform mainly depends on the diffusion distance and diffusion coefficient. The way to increase the diffusion distance is to increase the c / a value of the mandrel, and increasing the c / a value will increase the manufacturing cost of the mandrel. Fluorine-doped quartz glass can effectively prevent the diffusion of external hydroxyl groups to the core layer, and the corresponding reaction equation is:

[0075]

[0076] Adopt No. 5 mandrel in embodiment one, incr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com