Post vulcanization free silicon rubber formula

A technology of two-stage vulcanization and silicone rubber, which is applied in the field of rubber and can solve problems such as limiting production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Now in conjunction with two groups of embodiments the present invention is described in detail:

[0014] Second-stage vulcanization-free silicone rubber formula, the dosage is in parts by mass:

[0015] serial number

components

Example 1

Example 2

1

vinyl silicone rubber

100 copies

100 copies

2

40 copies

50 copies

3

3 copies

2.5 servings

4

0.8 parts

0.5 parts

5

2 copies

1.5 servings

6

DCBP

1.5 servings

1.5 servings

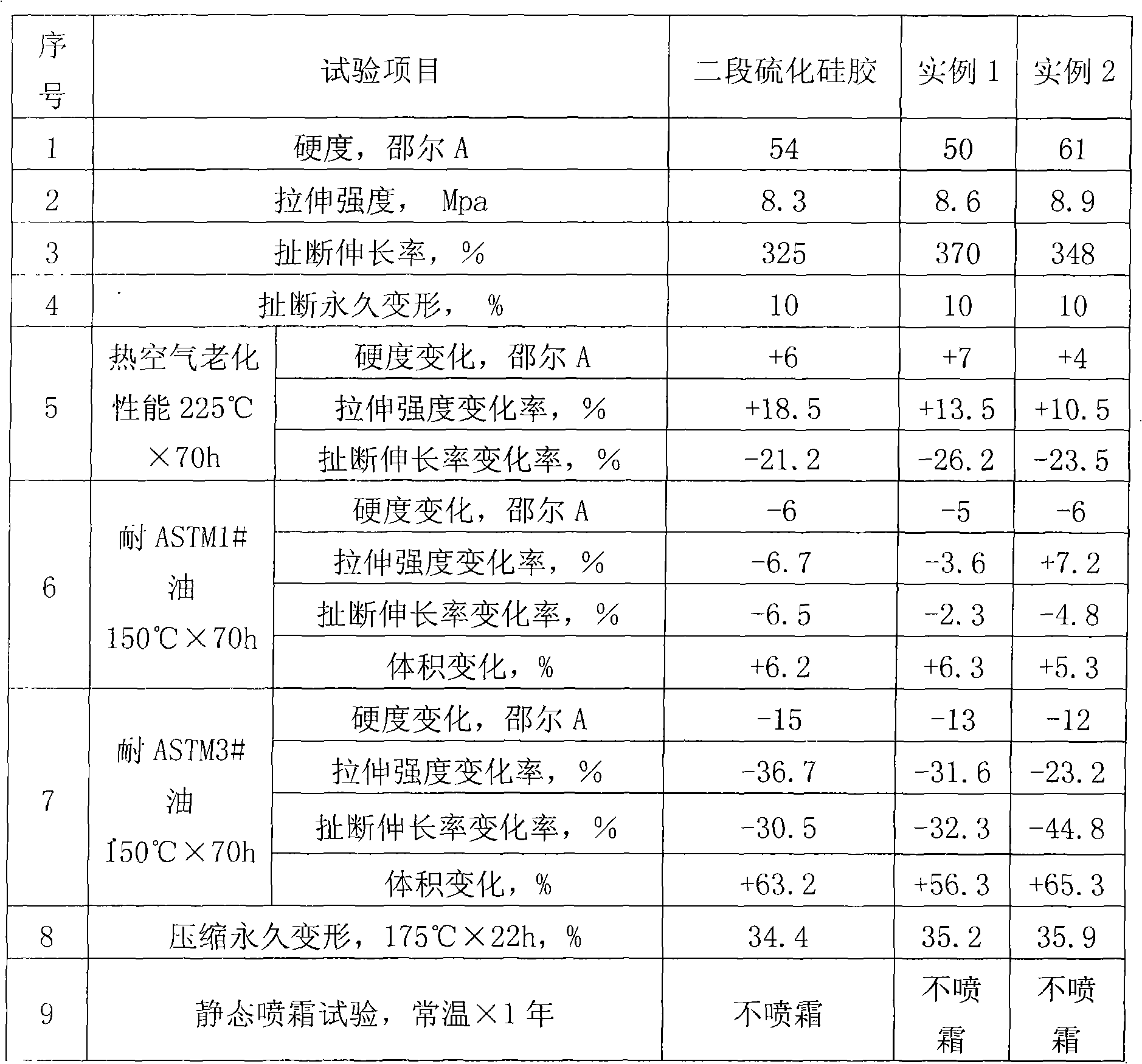

[0016] Mix the rubber according to the above formula, and vulcanize according to the vulcanization conditions of 120°C×10min×10MPa in Example 1 and Example 2. The properties of the rubber are as follows:

[0017]

[0018] The non-secondary vulcanization silicone rubber formula proposed by the present invention has been describe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap