Process for preparing and purifying Exendin-4 from colon bacillus

A technology of Escherichia coli and process, applied in the field of purification process of Exendin-4, can solve problems such as unsatisfactory yield and purity, achieve the effects of simple and easy operation steps, increase yield and purity, and simplify operation procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

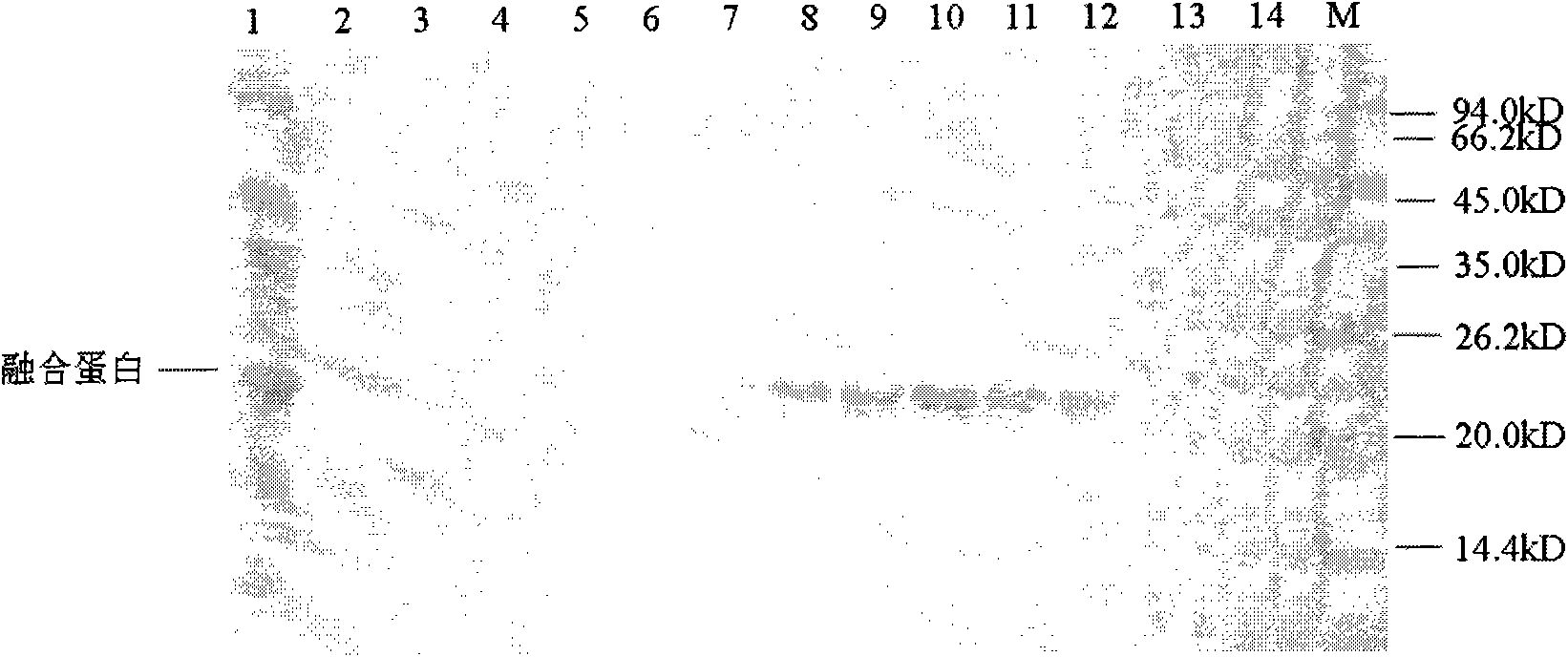

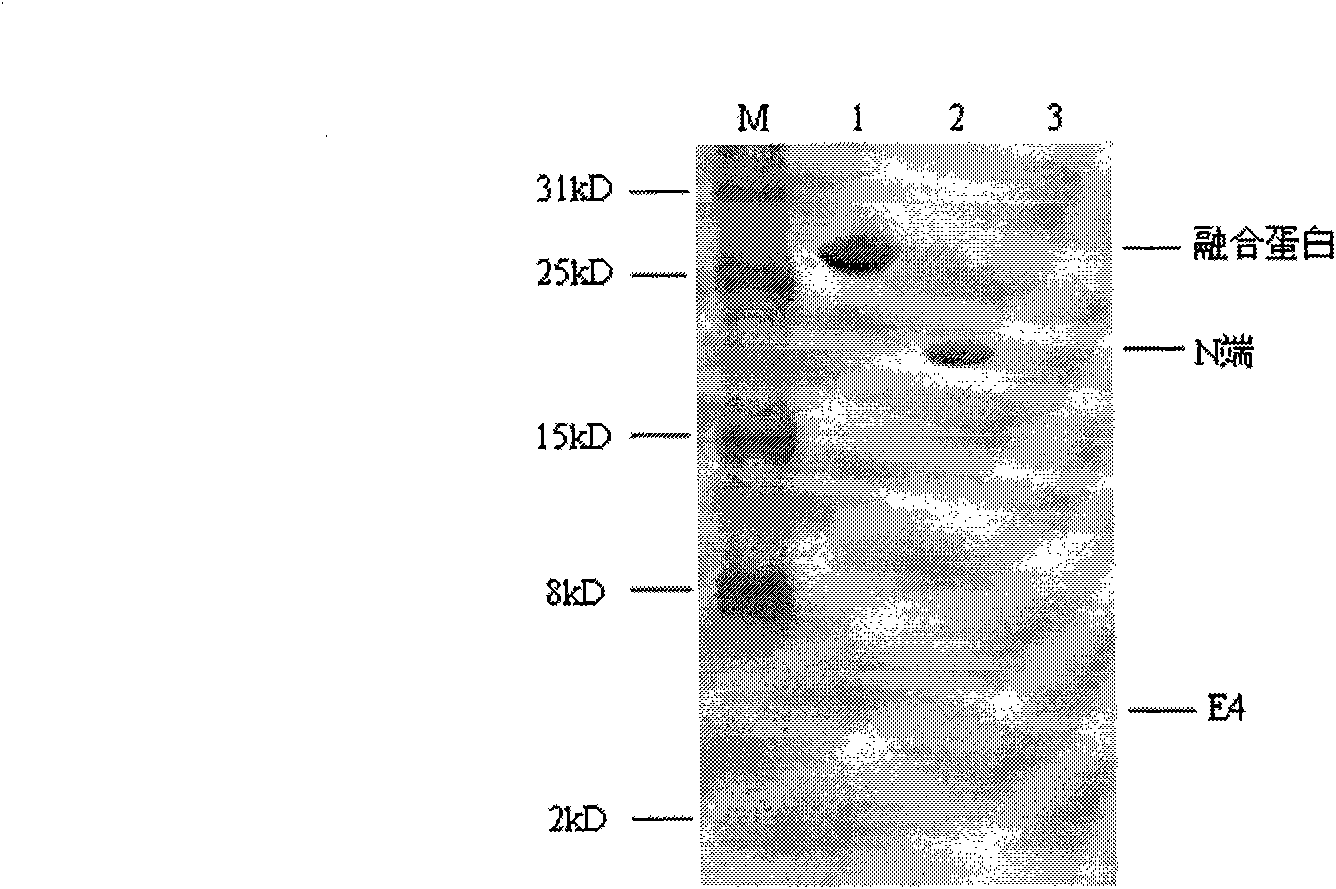

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in combination with specific embodiments.

[0021] 1. Preparation of reagents

[0022] (1) Configuration of lysis buffer 100ml

[0023] 50mMNaH 2 PO 4 0.690g NaH 2 PO 4 ·H 2 O (MW 137.99g / mol)

[0024] 300mM NaCl 1.754g NaCl (MW 58.44g / mol)

[0025] 10mM imidazole 0.068g imidazole (MW 68.08g / mol)

[0026] The pH was adjusted to 8.0 with NaOH.

[0027] Add now: Trition 100, 0.01%; Glycerol, 2%; β-mercaptoethanol, 10mM; PMSF, 0.1%; 100mM MgCl 2 , 1mM; 100mM MnCl 2 , 1mM; RNase, 1U; DNase, 1U

[0028] (2) Preparation of 100ml of washing buffer

[0029] 50mM NaH 2 PO 4 0.690g NaH 2 PO 4 ·H 2 O (MW 137.99g / mol)

[0030] 300mM NaCl 1.754g NaCl (MW 58.44g / mol)

[0031] 20mM imidazole 0.068g imidazole (MW 68.08g / mol)

[0032] The pH was adjusted to 8.0 with NaOH.

[0033] Add now: glycerol, 2%; β-mercaptoethanol, 10mM

[0034] (3) Preparation of 100ml of elution buffer

[0035] 50mM NaH 2 PO 4 0.6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com