Core-shell structured polyvinylidene fluoride/polycarbonate superfine fiber and preparing method thereof

A polyvinylidene fluoride and polycarbonate technology, which is used in fiber processing, filament/thread forming, and conjugated synthetic polymer rayon, etc. Superfine fibers, difficult to effectively adjust the properties of multi-component polymer electrospinning solution, etc.

Inactive Publication Date: 2011-01-05

TIANJIN UNIV

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, when some specific multi-component polymer systems are used for electrospinning, due to the limitation of the type and composition of polymer raw materials, it is often not easy to conduct multi-component electrospinning only by adjusting the relative content and relative molecular weight of polymers and other factors. The properties of polymer electrospinning liquid can be effectively adjusted, which cannot make it suitable for the preparation conditions of core / shell structure fibers, making it difficult to prepare ultrafine fibers with obvious core / shell structure in electrospinning

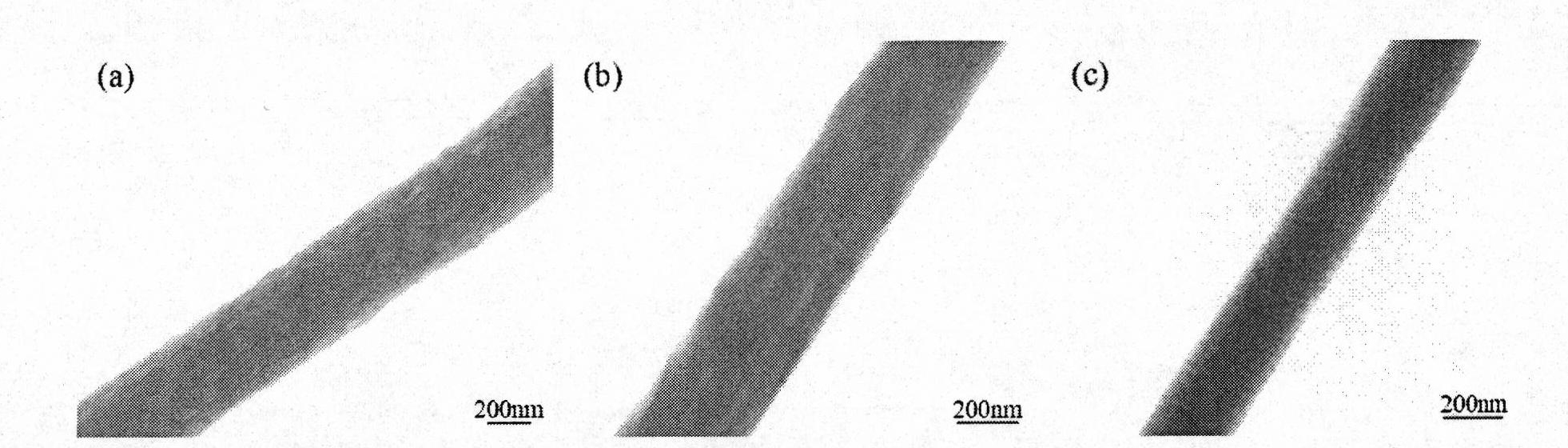

The inventor of this patent application used N,N-dimethylformamide (DMF) and tetrahydrofuran (THF) as a mixed solvent to electrospin the multi-component polymer system of PVDF / PC, and adjusted the electrospinning method respectively. While obtaining electrospun fibers with uniform morphology, as shown in Figure 1, the obtained electrospun fibers can only produce multi-phase continuous structures and different Obvious core / shell structure, the boundary between the core and the shell in the fiber is not obvious

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The present invention relates to a core-shell structured polyvinylidene fluoride (PVDF) / polycarbonate (PC) superfine fiber and a preparing method thereof. The PC and PVDF are used as raw materials, and the PMMA or BTEAC is added for preparing according to a proportion PVDF / PC=7-9 / 1-3. The adding amount of the PMMA or the BTEAC is respectively 5-20wt% and 1-4wt% of the total mass of the PC and thePVDF, and the diameter of the obtained fiber is 300-500nm. The preparing method of the invention specifically comprises the following processing steps: adding PMMA or benzyl triethyl ammonium chlorideinto the solution of the DMF / THF mixed solvent of PC, then addign the PVDF and DMF, mixing for obtaining the PVDF / PC dispersion containing PMMA or BTEAC as the electrospinning solution, and injectingthe electrospinning solution into an electrospinning device for electrospinning. According to the invention, the PVDF / PC multi-component polymer electrospinning solution is modified through adding athird component (PMMA or BTEAC) into the PVDF / PC electrospinning solution so that the modified PVDF / PC electrospinning solution can form the superfine fiber which has uniform fiber appearance and complete core / shell structure in electrospinning. The preparing method is easy and feasible, and is suitable for preparing the superfine fiber with evident core / shell structure in electrospinning with other multi-component polymer system.

Description

Polyvinylidene fluoride / polycarbonate superfine fiber with core-shell structure and preparation method technical field The present invention relates to a kind of polyvinylidene fluoride (PVDF) / polycarbonate (PC) microfiber of core-shell structure and preparation method, it is the method for preparing PVDF / PC superfine fiber with obvious core / shell structure, It belongs to the preparation technology of superfine fiber with special structure. Background technique Electrospinning of multi-component polymer blend solutions can be used to prepare nanoscale ultrafine fibers with a core / shell structure, and because the core and shell of ultrafine fibers can be prepared separately by selecting different types of polymers, and In order to achieve the performance that single-component polymer fibers cannot have at the same time, multi-component polymer fibers with a core / shell structure have broad application prospects in filter membranes, sensors, and the like. Polybutadiene (PB)...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): D01F8/10D01F8/16D01D5/34

Inventor 袁晓燕那海宁刘希望

Owner TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com