Lithium ion battery electrolyte and preparation method thereof

A lithium-ion battery and electrolyte technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems that pure aramid nanofibers cannot be gelled, aramid solutes are precipitated, and the polymerization process is complicated, etc., and achieve excellent thermal stability. The effect of stability and mechanical properties, high production efficiency and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

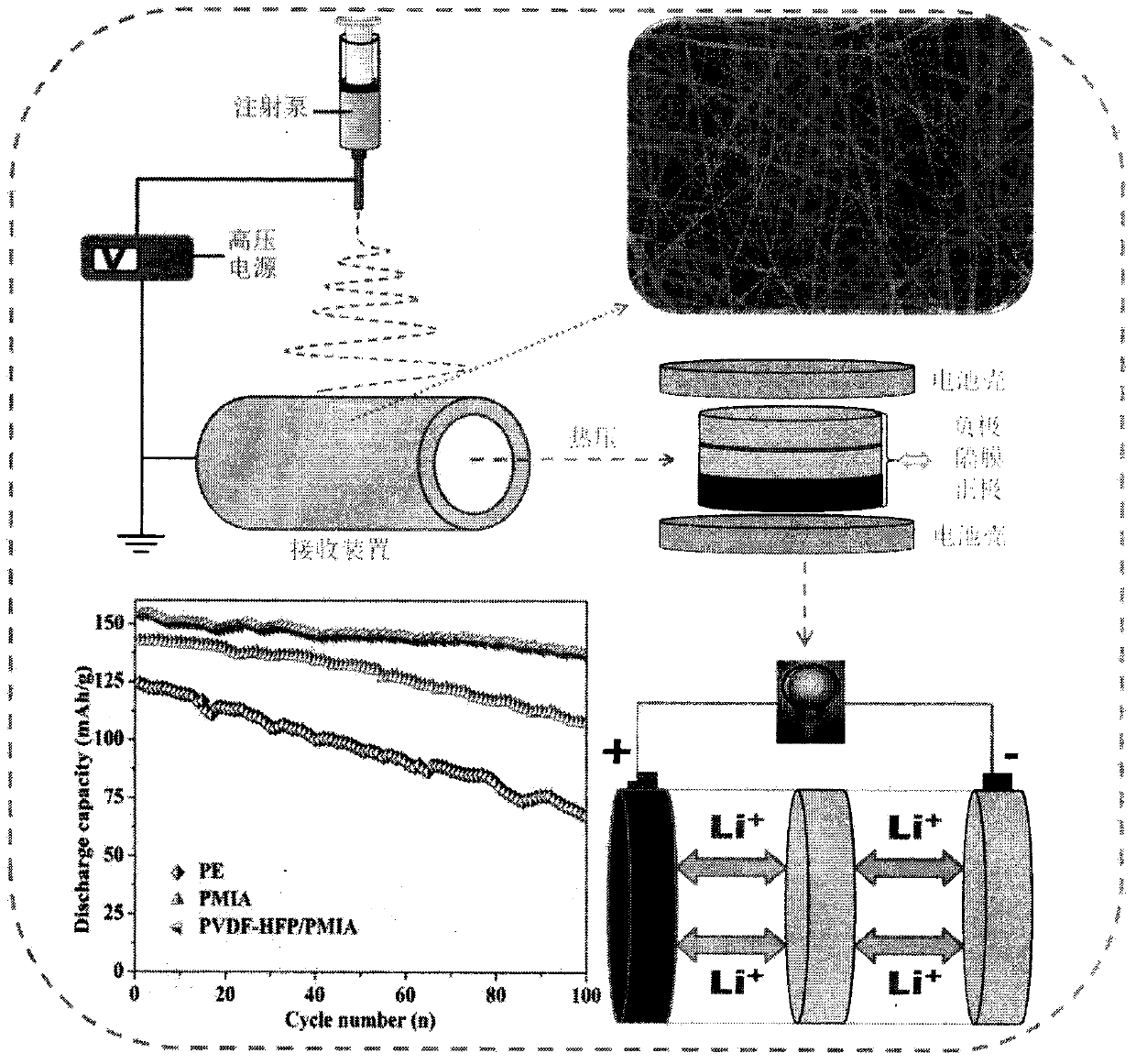

Method used

Image

Examples

Embodiment 1

[0022] (1) the aramid fiber emulsion that concentration is 15wt% is dissolved in dimethylacetamide (the ratio of the two volumes is 1: 5) in the organic solvent, utilizes magnetic stirrer to stir 6 hours under normal temperature condition then to form the homogeneous mixing solution, and then add a certain amount of polyvinylidene fluoride-hexafluoropropylene (PVDF-HFP) powder (ratio to the mass of aramid fiber is 1:0) in the aramid / dimethylacetamide mixture, and then the formed The polyvinylidene fluoride-hexafluoropropylene / aramid fiber mixture was stirred at high speed for 12 hours at room temperature to form a uniform and stable spinning solution.

[0023] (2) Slowly add the spinning solution configured in the above step (1) into the syringe, the inner diameter of the needle used is 0.3mm, and the extrusion rate of the needle solution is 0.2mL h -1 . A rotating cylinder covered with aluminum foil serves as a receiving device, and the receiving distance between the syringe...

Embodiment 2

[0026] (1) the aramid fiber emulsion that concentration is 20wt% is dissolved in dimethylacetamide (the ratio of the two volumes is 1: 5) in the organic solvent, utilizes magnetic stirrer to stir 6 hours under normal temperature condition then to form the homogeneous mixing solution, and then add a certain amount of polyvinylidene fluoride-hexafluoropropylene (PVDF-HFP) powder (ratio to the mass of aramid fiber is 20:1) in the aramid / dimethylacetamide mixture, and then the formed The polyvinylidene fluoride-hexafluoropropylene / aramid fiber mixture was stirred at high speed for 12 hours at room temperature to form a uniform and stable spinning solution.

[0027] (2) Slowly add the spinning solution configured in the above step (1) into the syringe, the inner diameter of the needle used is 0.35mm, and the extrusion rate of the needle solution is 0.4mL h -1 . A rotating cylinder covered with aluminum foil serves as a receiving device, and the receiving distance between the syrin...

Embodiment 3

[0030](1) the aramid fiber emulsion that concentration is 25wt% is dissolved in dimethylacetamide (the ratio of the two volumes is 1: 5) organic solvent, utilizes magnetic stirrer to stir 6 hours under normal temperature condition then to form the homogeneous mixing Solution, and then add a certain amount of polyvinylidene fluoride-hexafluoropropylene (PVDF-HFP) powder (ratio to the mass of aramid fiber is 10:1) in the aramid / dimethylacetamide mixture, and then the formed The polyvinylidene fluoride-hexafluoropropylene / aramid fiber mixture was stirred at high speed for 12 hours at room temperature to form a uniform and stable spinning solution.

[0031] (2) Slowly add the spinning solution configured in the above step (1) into the syringe, the inner diameter of the needle used is 0.4mm, and the extrusion rate of the needle solution is 0.6mL h -1 . A rotating cylinder covered with aluminum foil serves as a receiving device, and the receiving distance between the syringe tip an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com