Device and method for testing density, concentration and thickness based on X-ray

A testing device, X-ray technology, applied in measuring device, specific gravity measurement, using wave/particle radiation, etc., can solve the problems of ray intensity fluctuation, reduced detection accuracy, stroboscopic phenomenon, etc., and achieve low potential danger and high-precision detection. , safe and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

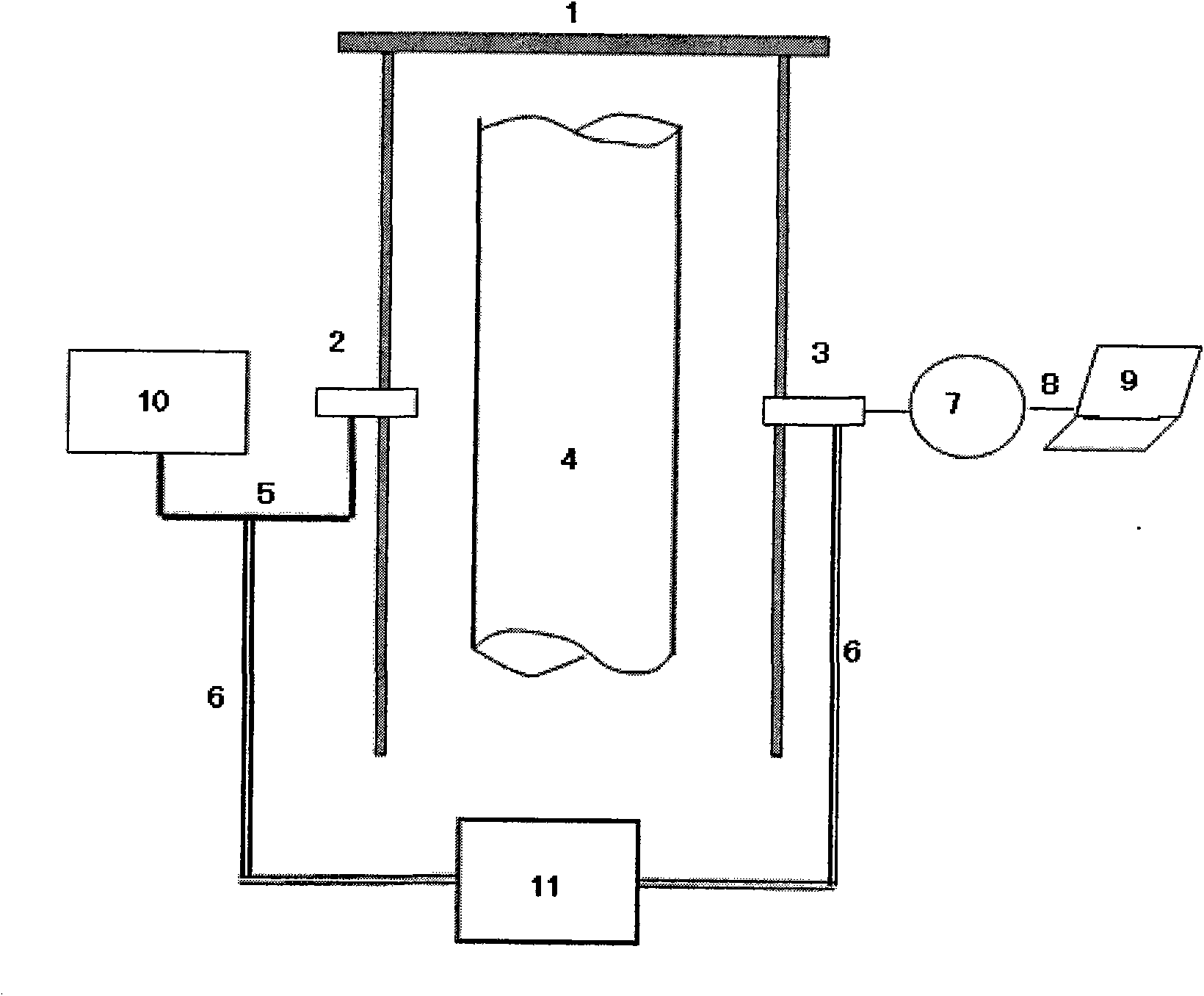

Embodiment 1

[0029] Embodiment 1: the mensuration of coal-water slurry density in pipeline (density range 1-2.5)

[0030] 1) Install the X-ray generator and reference counting tube on one side of the coal-water slurry delivery pipeline, and the working counting tube on the opposite side. During installation, adjust the distance between the reference counting tube and the X-ray axis, and the working counting tube The distance from the X-ray source, so that the radiation intensity measured by the counter tube is within a reasonable range;

[0031] 2) Measure 2 to 5 samples with known densities before use, and calculate the relationship between the signal intensity ratio of the reference counter tube and the working counter tube and the density or concentration of the substance to be measured by the least square method;

[0032] 3) According to the ratio of signal strength of working counting tube / signal strength of reference counting tube and the relational formula obtained in the second ste...

Embodiment 2

[0033] Embodiment 2: the mensuration of syrup concentration

[0034] 1) Install the X-ray generator and the reference counting tube on one side of the syrup container, and the working counting tube on the opposite side. During installation, adjust the distance between the reference counting tube and the X-ray axis, and the distance between the working counting tube and the X-ray axis. The distance from the X-ray source, so that the ray intensity measured by the counter tube is within a reasonable range;

[0035] 2) Measure 2 to 5 syrup samples with known concentrations before use, and calculate the relationship between the signal intensity ratio of the reference counter tube and the working counter tube and the density or concentration of the substance to be measured by the least square method;

[0036] 3) According to the ratio of the signal intensity of the working counter tube to the signal intensity of the reference counter tube and the relational expression obtained in step...

Embodiment 3

[0037] Embodiment 3: the mensuration of cardboard thickness

[0038] 1) Install the X-ray generator and reference counting tube on one side of the cardboard, and the working counting tube on the opposite side. During installation, adjust the distance between the reference counting tube and the X-ray axis, as well as the working counting tube and the X-ray source distance, so that the ray intensity measured by the counter tube is within a reasonable range;

[0039] 2) Measure 2 to 5 cardboards with known thickness before use, and calculate the relationship between the signal intensity ratio of the reference counter tube and the working counter tube and the thickness of the cardboard to be tested by the least square method;

[0040] 3) According to the ratio of the signal strength of the working counting tube / the signal strength of the reference counting tube and the relational formula obtained in step 2), the thickness of the cardboard can be obtained.

[0041] The present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com