Device and method for producing cold pressure welding compound rivet contacts

A technology of contact manufacturing and cold pressure welding, applied in the direction of manufacturing tools, welding equipment, non-electric welding equipment, etc., can solve the problems of low bonding strength, high cost, unfavorable automatic production and other problems of cladding, and achieve precise control of cladding thickness, Excellent performance-price ratio and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The embodiments of the present invention are described in detail below: the present embodiment is implemented under the premise of the technical solution of the present invention, and detailed implementation and specific operation process are provided, but the protection scope of the present invention is not limited to the following implementation example.

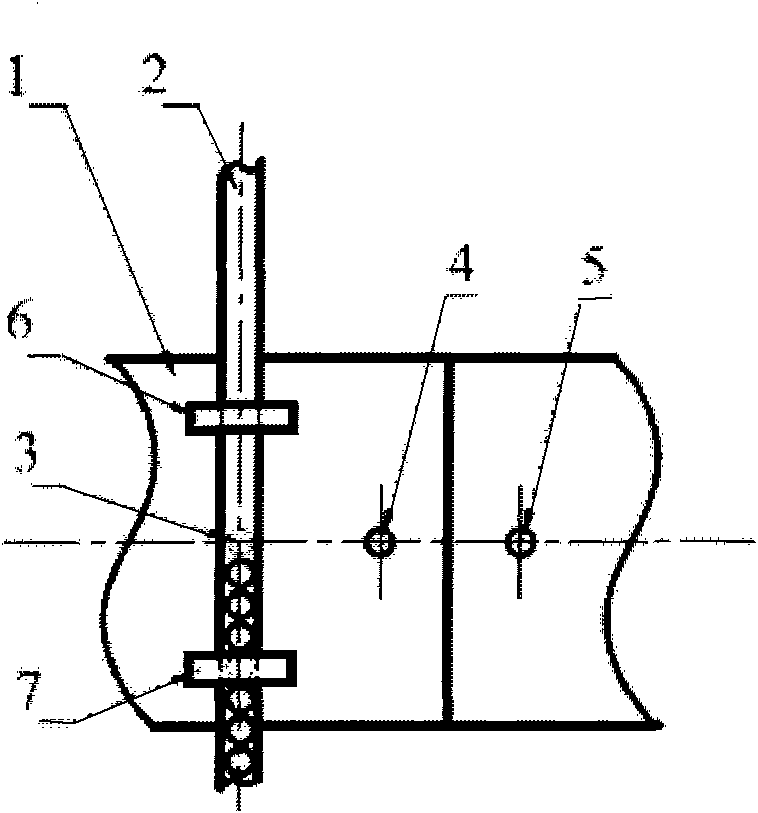

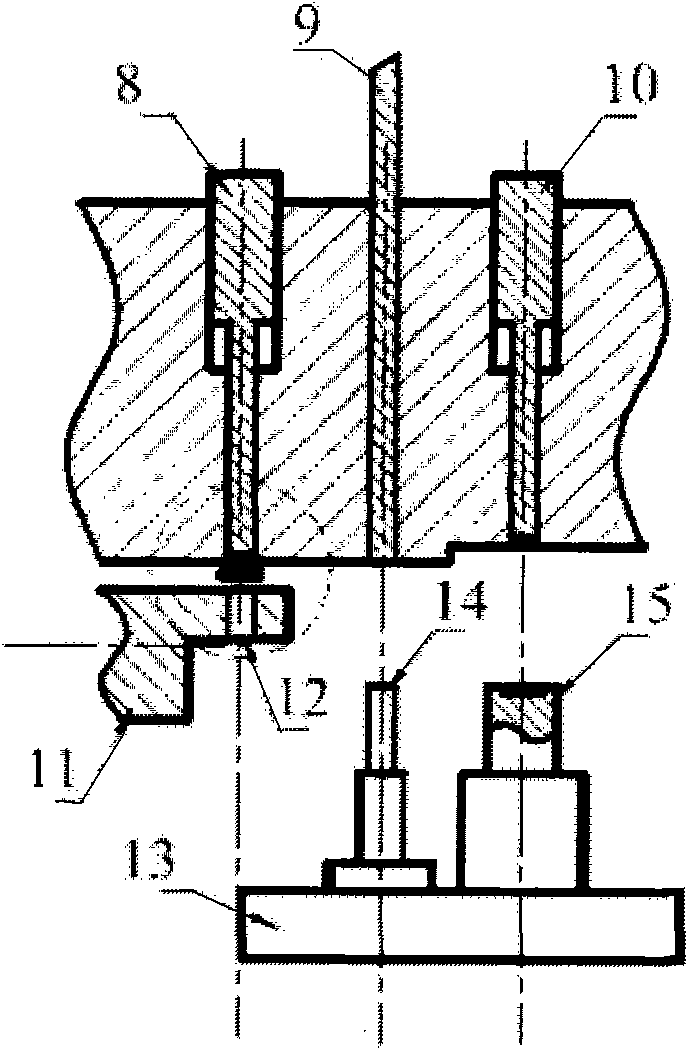

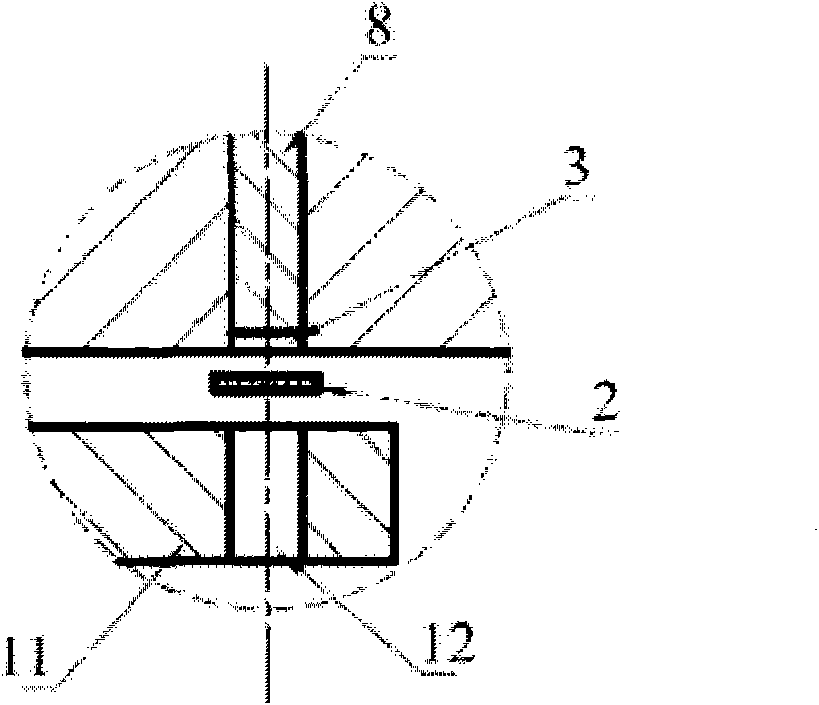

[0034] Such as figure 1 with figure 2 As shown, this embodiment includes: a main base 1, a composite strip 2, a die guide hole 3, a wire feeding guide hole 4, a stripping guide hole 5, an upper positioning fixture 6, a lower positioning fixture 7, a strip punch Head 8, copper wire 9, stripping punch 10, material knife 11, material collecting hole 12, upsetting mold base 13, pre-upsetting mold 14 and forming upsetting mold 15, wherein: the main base 1 is horizontal from left to right There are punching guide holes 3, wire material feeding guide holes 4, and stripping guide holes 5. There are upper positioning fixt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com