Inner cavity type multiple-active region photon crystal vertical cavity surface transmission semiconductor laser device

A vertical cavity surface emission and photonic crystal technology, applied in the field of optoelectronics, can solve the problems of poor thermal stability of devices, difficulty in controlling small oxidation holes, low single-mode output power, etc., to achieve improved thermal stability and narrow line width , the effect of emphasizing the modulation characteristics

Inactive Publication Date: 2011-01-05

BEIJING UNIV OF TECH

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Such a small oxide pore size will inevitably lead to a large series resistance

At the same time, a large series resistance will inevitably generate a lot of heat, which will deteriorate the thermal stability of the device.

It is difficult to control the process of making small oxidation holes 9

The smaller oxidation hole 9 makes the effective light-emitting area smaller and the single-mode output power is low

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

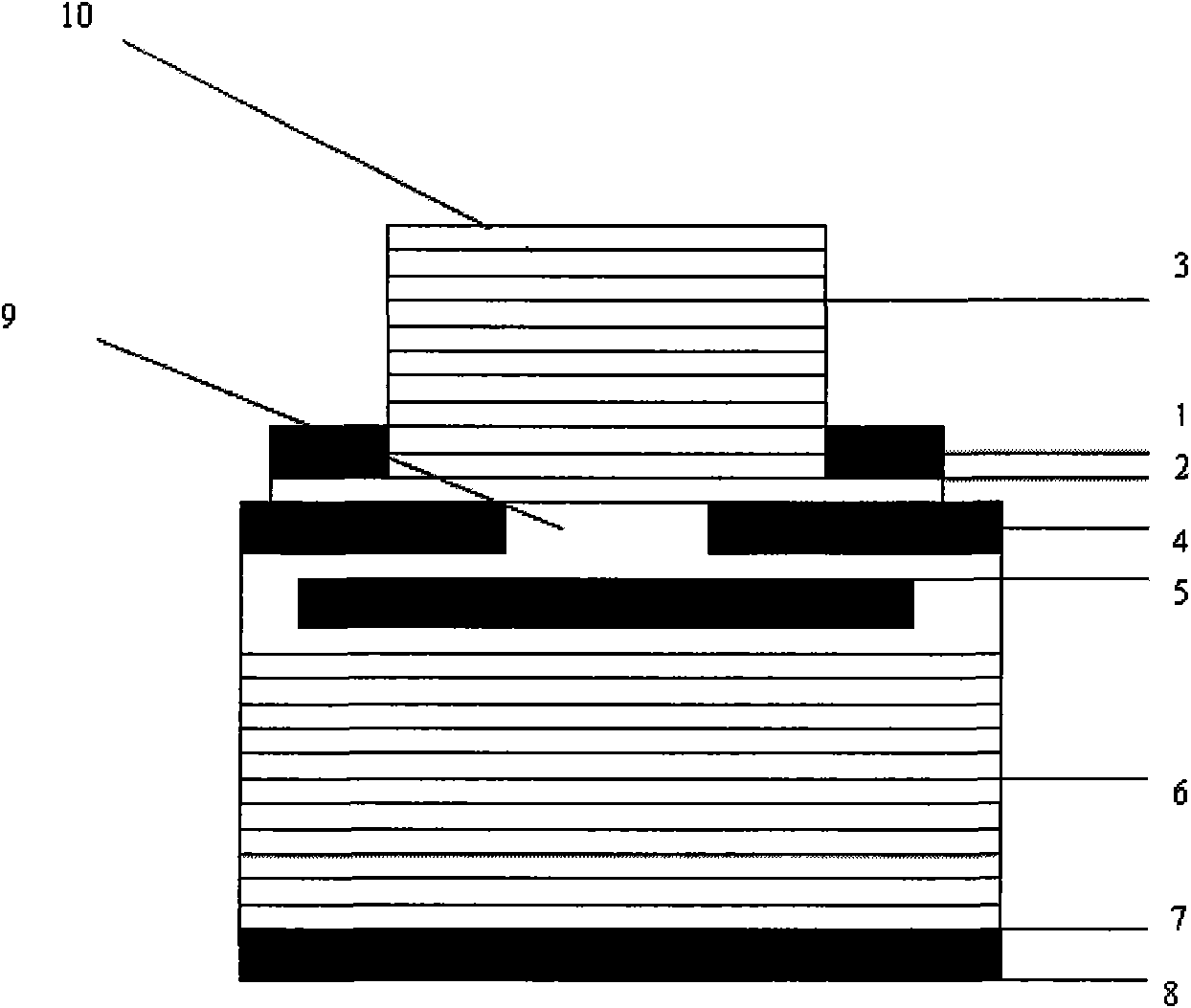

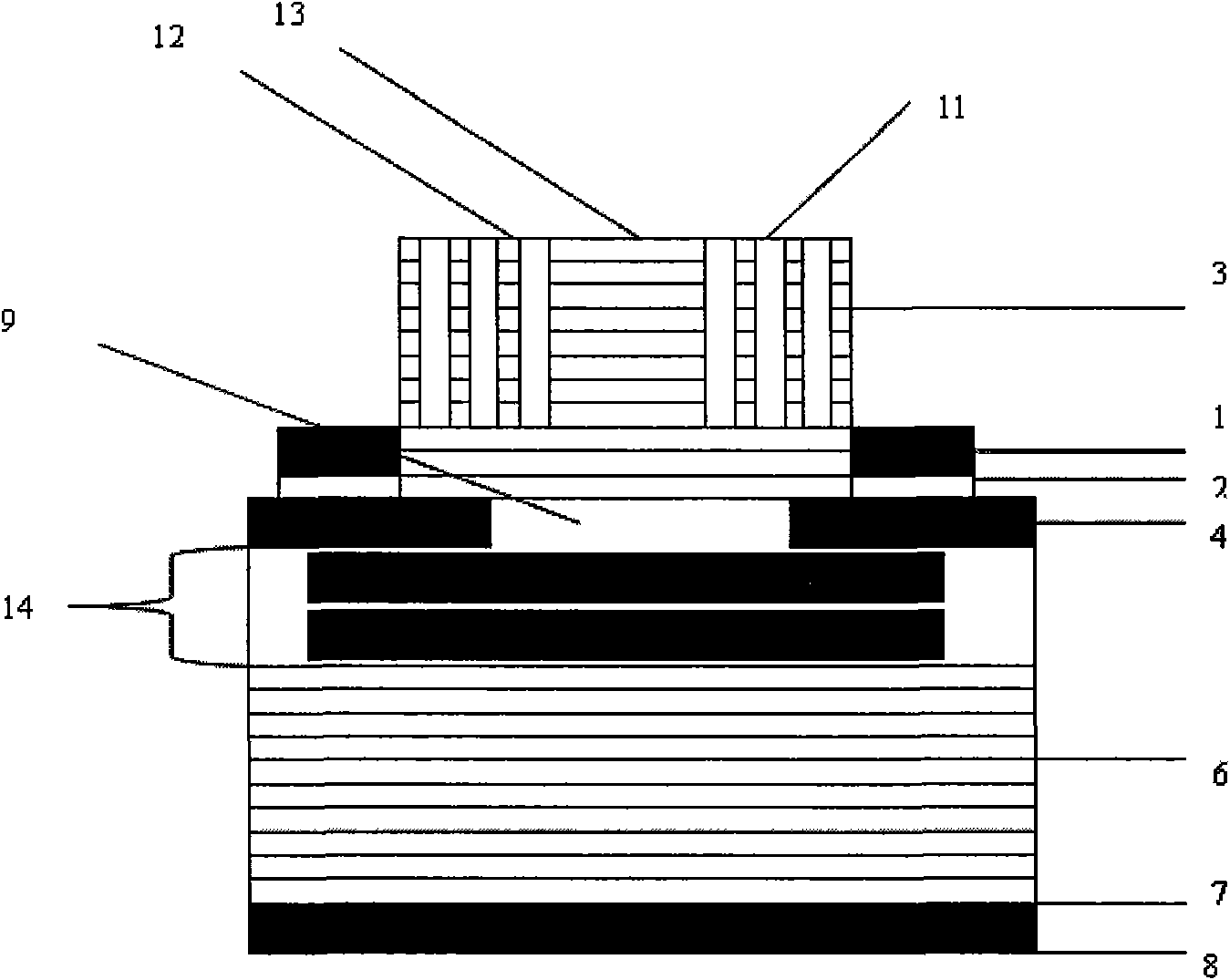

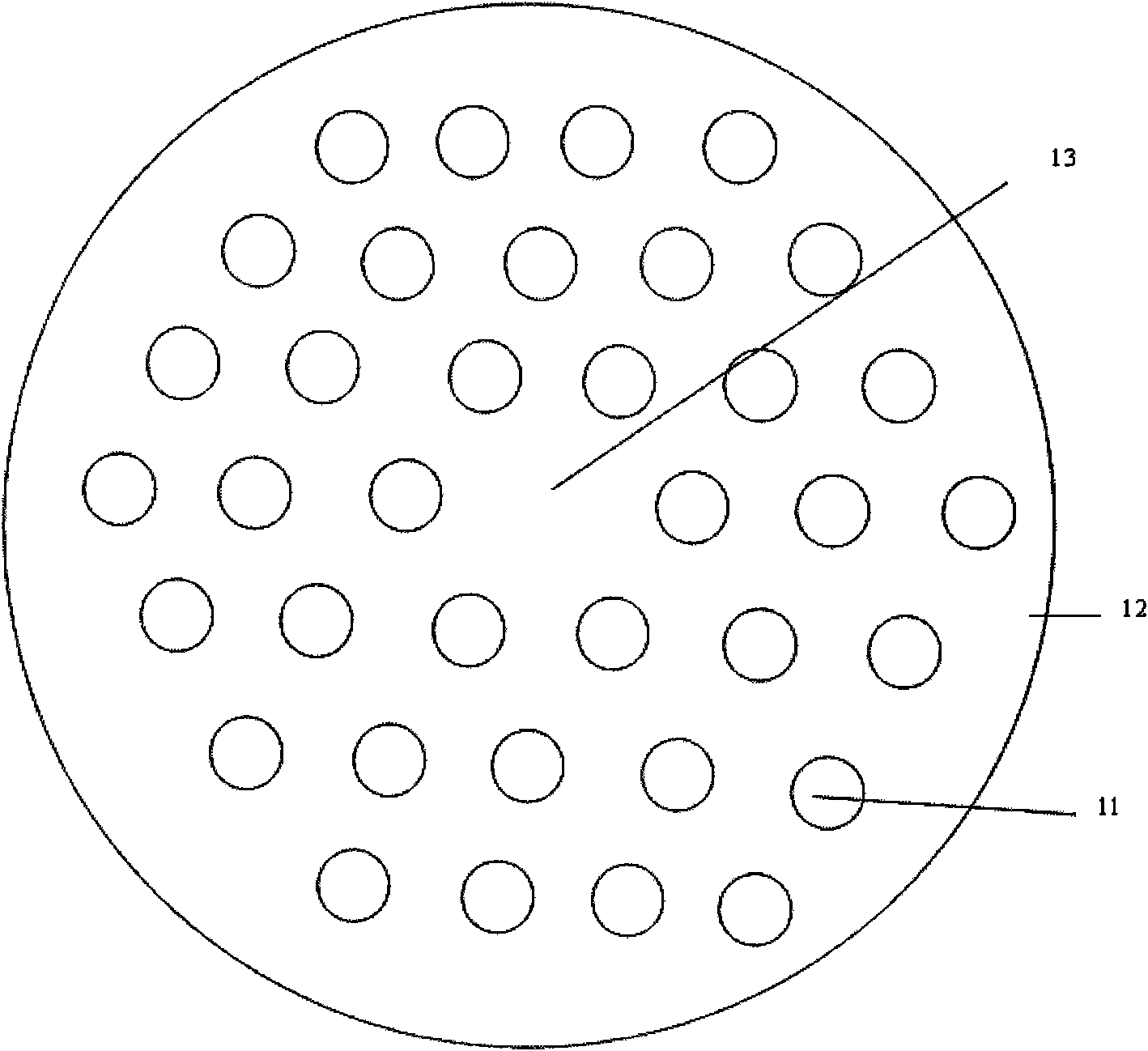

The invention relates to an inner cavity type multiple-active region photon crystal vertical cavity surface transmission semiconductor laser device, belonging to the semiconductor photoelectron field.The common oxidation limiting vertical cavity surface transmission semiconductor laser device has problems of multiple-transverse module laser shooting, low single module output power, large threshold current and large series resistance and so on. The invention adopts the multiple-active region structure on the active region of the device, meanwhile leads the defect type photon crystal structureinto DBR on the vertical cavity surface transmission semiconductor laser device, the inner cavity type multiple-active region photon crystal vertical cavity surface transmission semiconductor laser device with dozens of micrometres of single module operation oxidation bore diameter, dozens of mws of single module power, dozens of Ohms of series resistances and more than 40 dbs of side module inhibition can be obtained by optimizing the photon crystal period, the air bore diameter, the etching depth, the device diameter and the oxidation bore diameter and so on reasonably.

Description

Intra-cavity multi-active area photonic crystal vertical cavity surface-emitting semiconductor laser technical field The invention belongs to the technical field of optoelectronics, and in particular relates to the design and manufacture of a novel vertical cavity surface emitting semiconductor laser. Background technique Vertical cavity surface emitting laser (VCSEL) has the advantages of low threshold current, dynamic single longitudinal mode operation, small divergence angle, circular symmetric beam, high modulation bandwidth, easy two-dimensional integration, etc., and can be widely used in optical communication, optical storage and optical display and other fields. Common oxidation-limited vertical-cavity surface-emitting semiconductor lasers are structurally divided into two types: inner-cavity and outer-cavity. The material of the inner-cavity vertical-cavity surface-emitting semiconductor laser is mainly composed of III-V compound semiconductor materials through m...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01S5/183H01S5/065H01S5/06H01S5/20

Inventor 徐晨解意洋沈光地陈弘达阚强王春霞刘英明王宝强

Owner BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com