Method and device for cleaning fresh and alive sea cucumbers suitable for continuous production

A sea cucumber, fresh technology, applied in the direction of fish cleaning/descaling, climate change adaptation, etc., can solve the problems of unsatisfactory cleaning effect, soft and easily damaged ginseng body, and unfavorable continuous production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

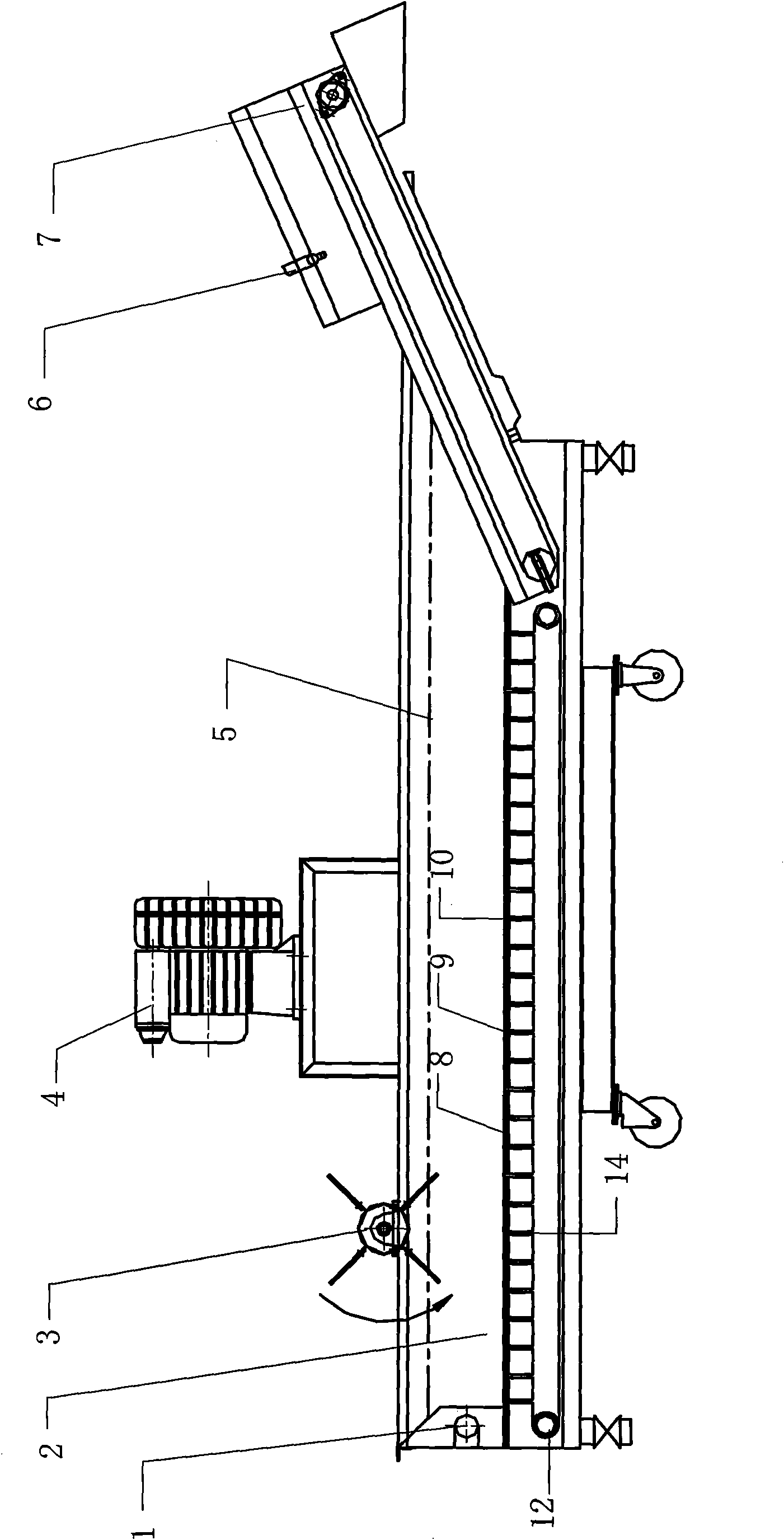

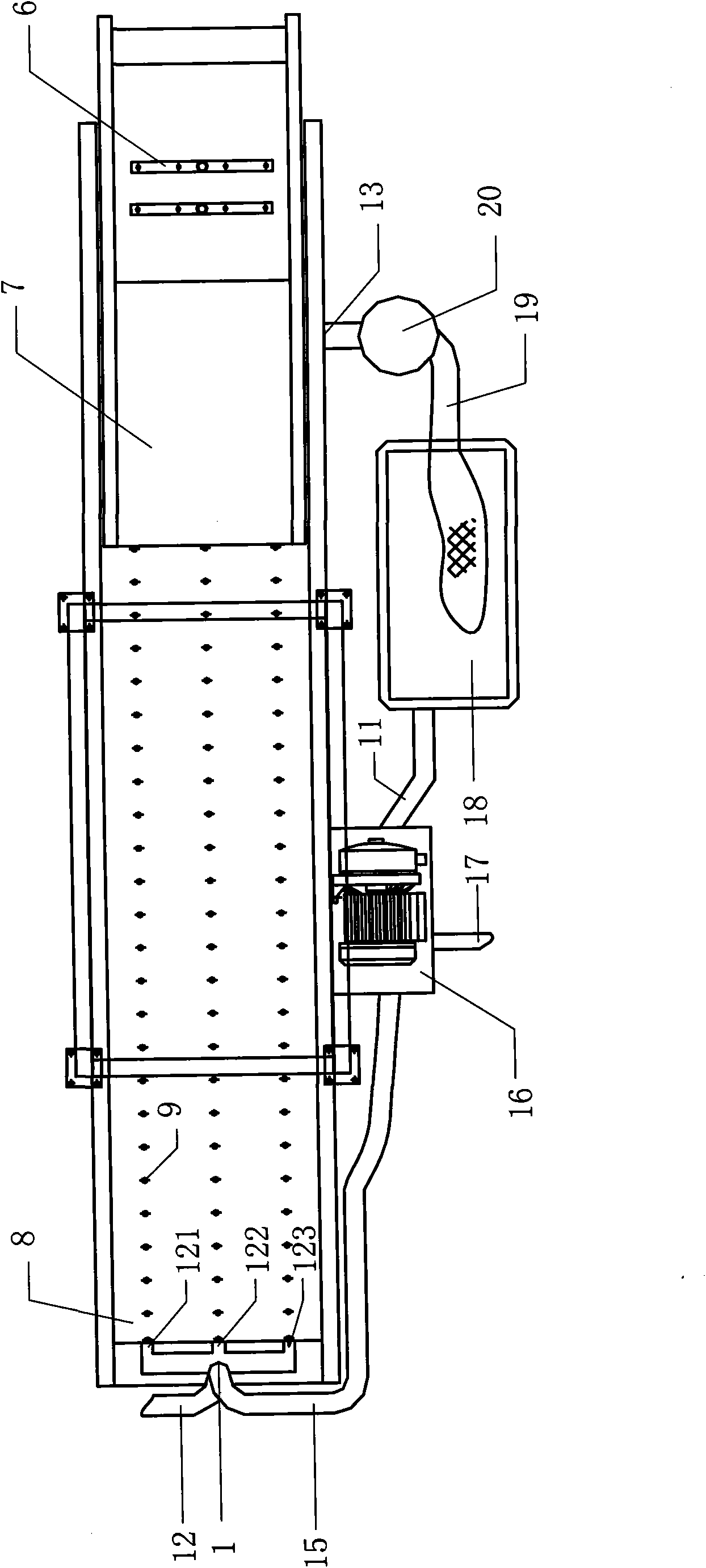

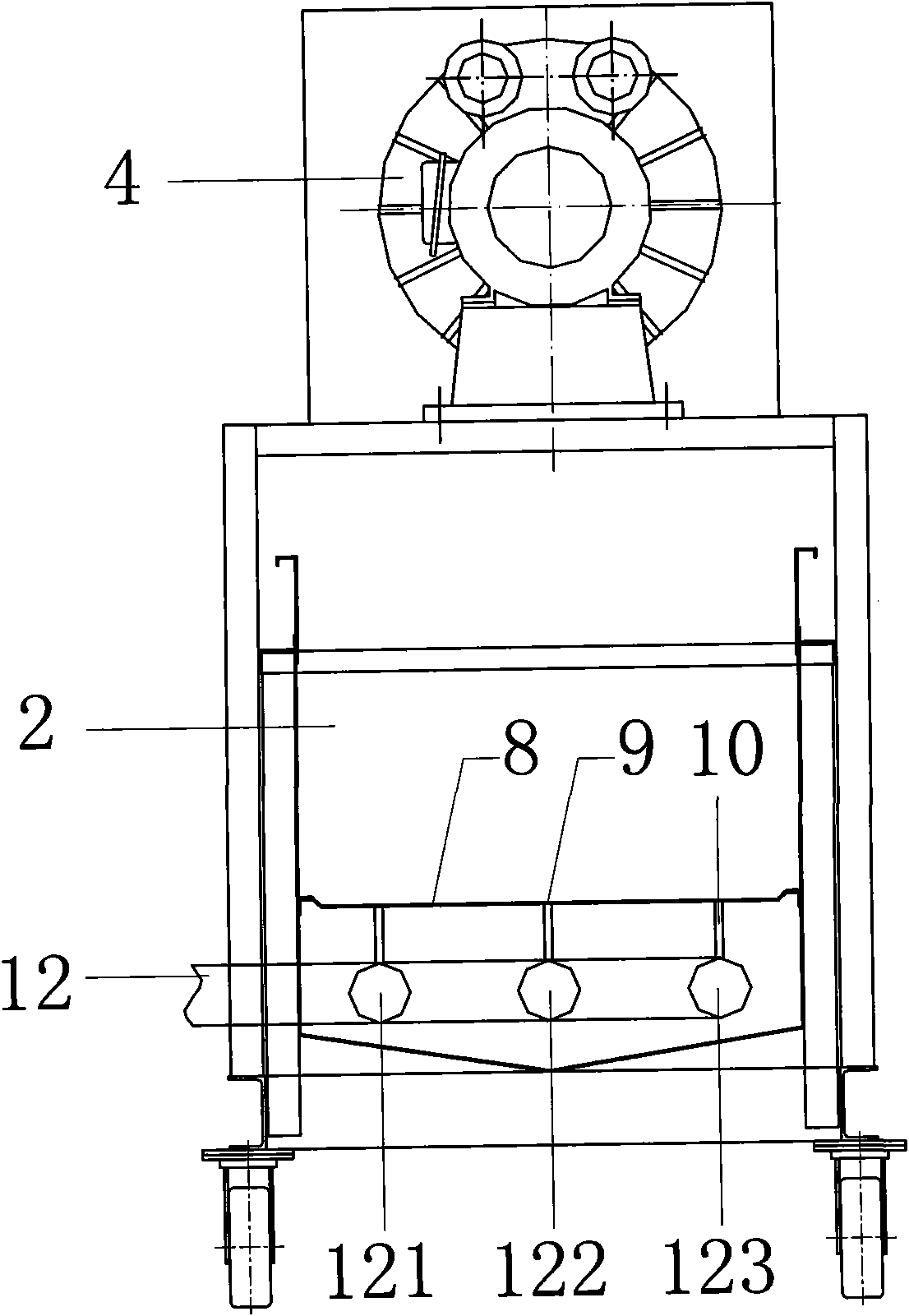

[0026] The present invention will be further described below in conjunction with accompanying drawing.

[0027] A preferred solution is to install nozzles 10 on the jet holes 14 of the gas delivery pipe 12, the diameter of the sieve hole 9 on the sieve plate 8>the outer diameter of the nozzle, and the upper end of the nozzle 10 is slightly lower than the upper side of the sieve plate 8, such as Figure 4 As shown, since the sieve holes 9 and the nozzles 10 are densely arranged, the diameter of the sieve holes is designed to be slightly larger than the outer diameter of the nozzle, and the precision requirements for processing and installation will be reduced, but the size of the sieve holes 9 should not be too large. If it is too large, the sea cucumber will easily fall into the bottom of the water tank 2 below the sieve plate 8 from the gap between the sieve hole 9 and the nozzle 10, so usually the diameter of the sieve hole is not greater than 40mm, and the upper end of the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com