Filter bag for fibre analysis and manufacturing method thereof

A filter bag and fiber technology, applied in the separation method, filter separation, gravity filter, etc., can solve the problems of residue transfer loss, small batch size, and easy filter blockage, etc., to achieve easy filter blockage, high-efficiency filtration, and high filtration efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

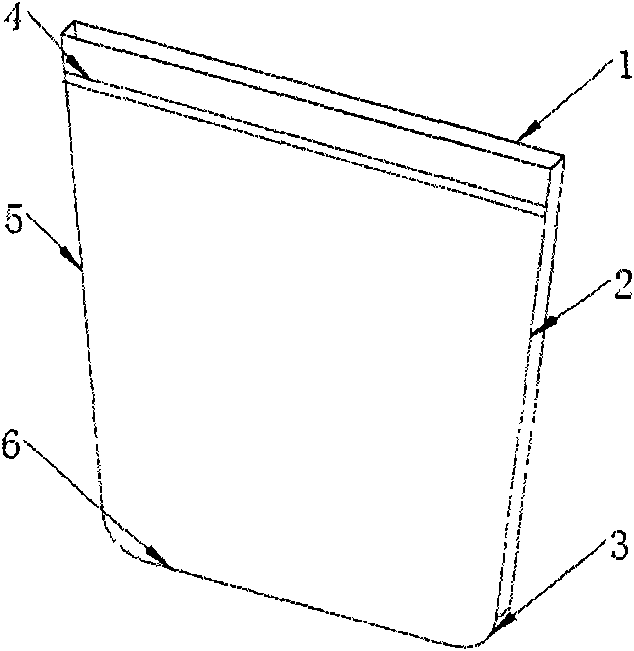

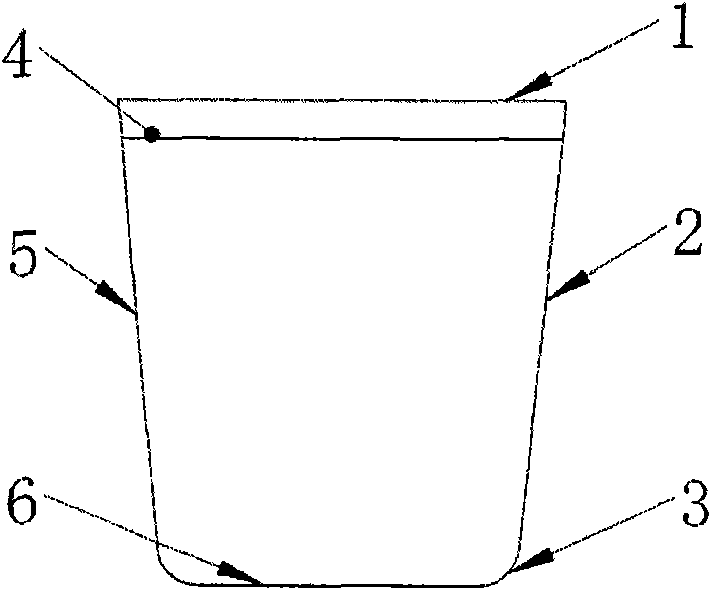

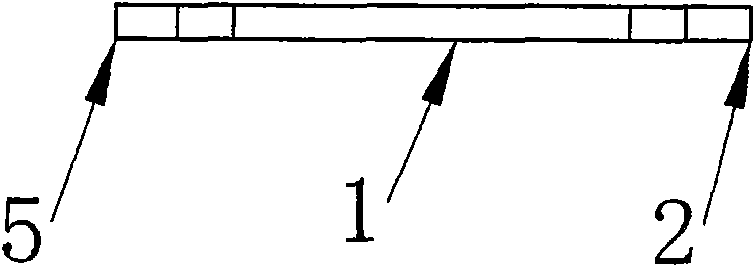

[0027] Such as Figure 1-6 As shown, the filter bag of the present invention is made of polypropylene melt-blown ultrafine fiber material, and its shape is U-shaped, with an opening on the upper part, and a space that can be loaded with samples is formed in the middle part. The fiber fineness of polypropylene melt-blown microfiber material should be less than 4μm, the filtration efficiency should be greater than 99%, the resistance should be less than 7Pa, and the fixed volume should be 55-60g / m 2 ;And the acid resistance of polypropylene melt-blown microfiber material is greater than 0.255mol / L sulfuric acid, the alkali resistance is greater than 0.313mol / L potassium hydroxide, and the heat resistance is greater than 110°C. After burning, it has no ash and does not contain nitrogen. Strong heat seal.

[0028] The thickness of the U-shaped filter bag is 0.28mm, the upper side 1 is 56mm long, the lower side, that is, the bottom side 6 is 44mm long, the hypotenuse of the left s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com