Separating device and separating method for self streaming gas-solid magnetic field fluidized bed

A sorting device and fluidized bed technology, applied in the field of dry sorting, can solve problems such as difficult control of operating parameters and technical indicators, complex structure, etc., achieve good sorting effect, improve sorting accuracy, and reduce the lower limit of sorting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

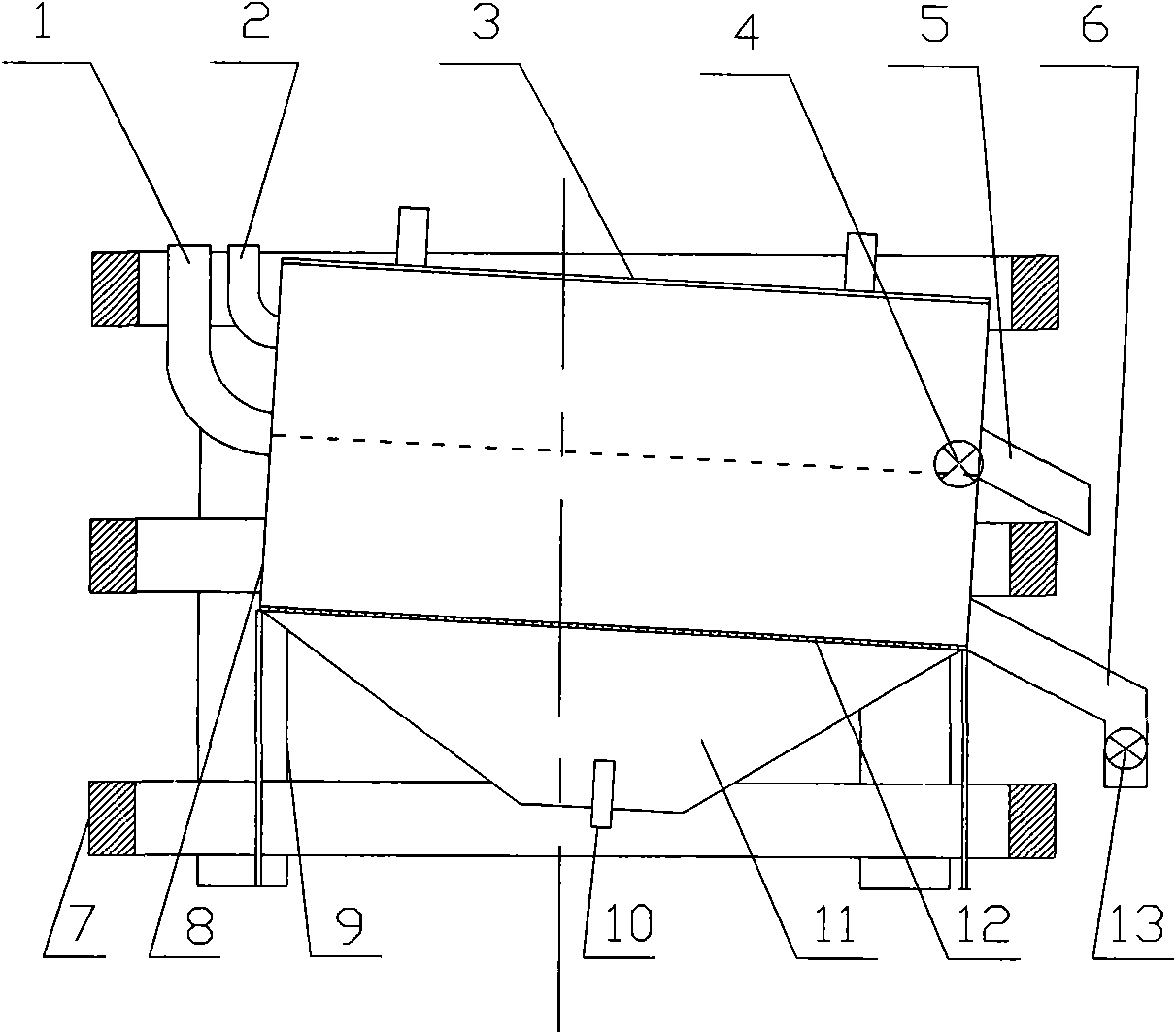

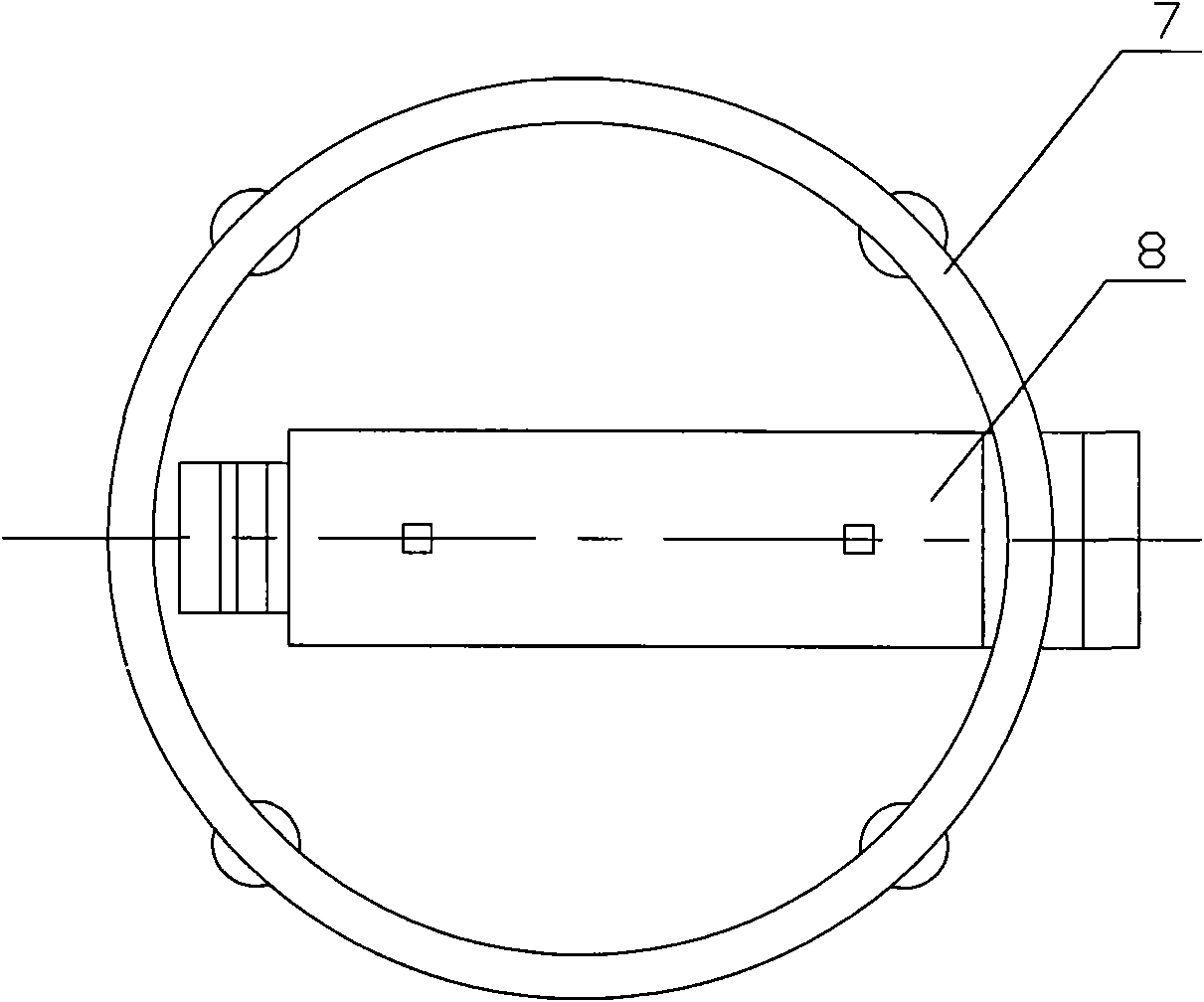

[0011] The magnetic field fluidized bed separation device of the present invention is mainly composed of a fluidized bed body 8 arranged obliquely, an air distribution plate 12 , an air chamber 11 , and a multi-turn Helmholtz coil 7 . The front part of the fluidized bed body 8 is connected with the medium chute 1 and the raw coal chute 2 through bolts, and the tail part of the fluidized bed body 8 is connected with the overflow chute 5 and the underflow chute 6 through bolts, and the feed end of the overflow chute 5 is provided with Float discharge impeller 4, underflow discharge impeller 13 is provided at the discharge end of underflow chute 6; upper sealing cover 3 is provided on the upper part of fluidized bed body 8; air distribution plate is connected to the lower part of fluidized bed body 8 by bolts 12. The air distribution plate 12 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com